Drying device for containers and method for cleaning such a drying device

A cleaning and container technology, applied in the field of drying devices for containers and for cleaning such drying devices, can solve the problems of time-consuming operators, discomfort, prolonged time interval, etc., and achieve the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

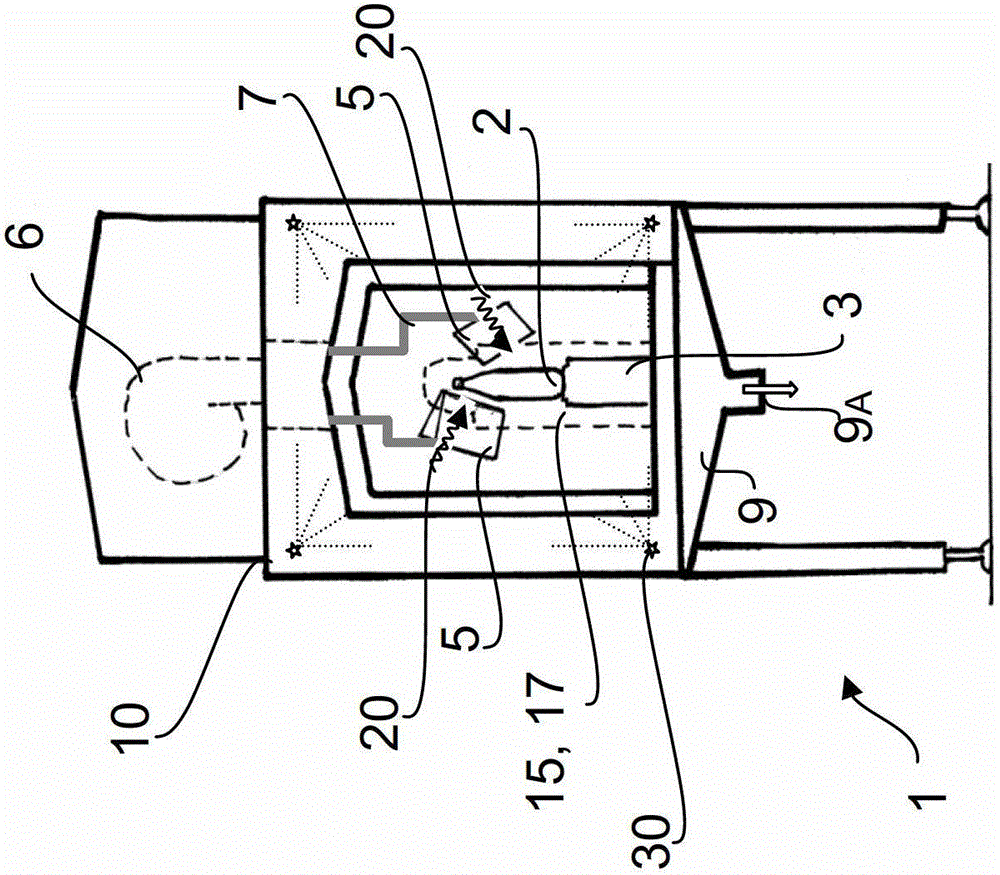

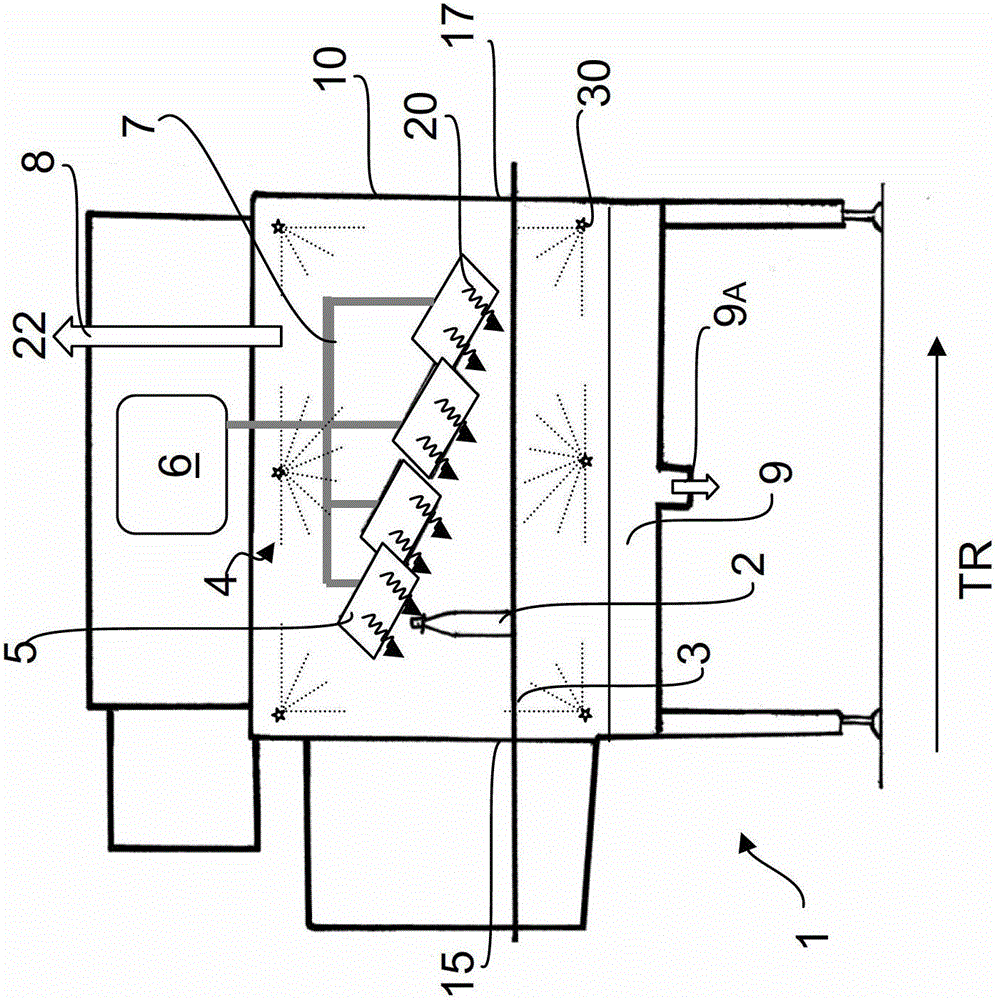

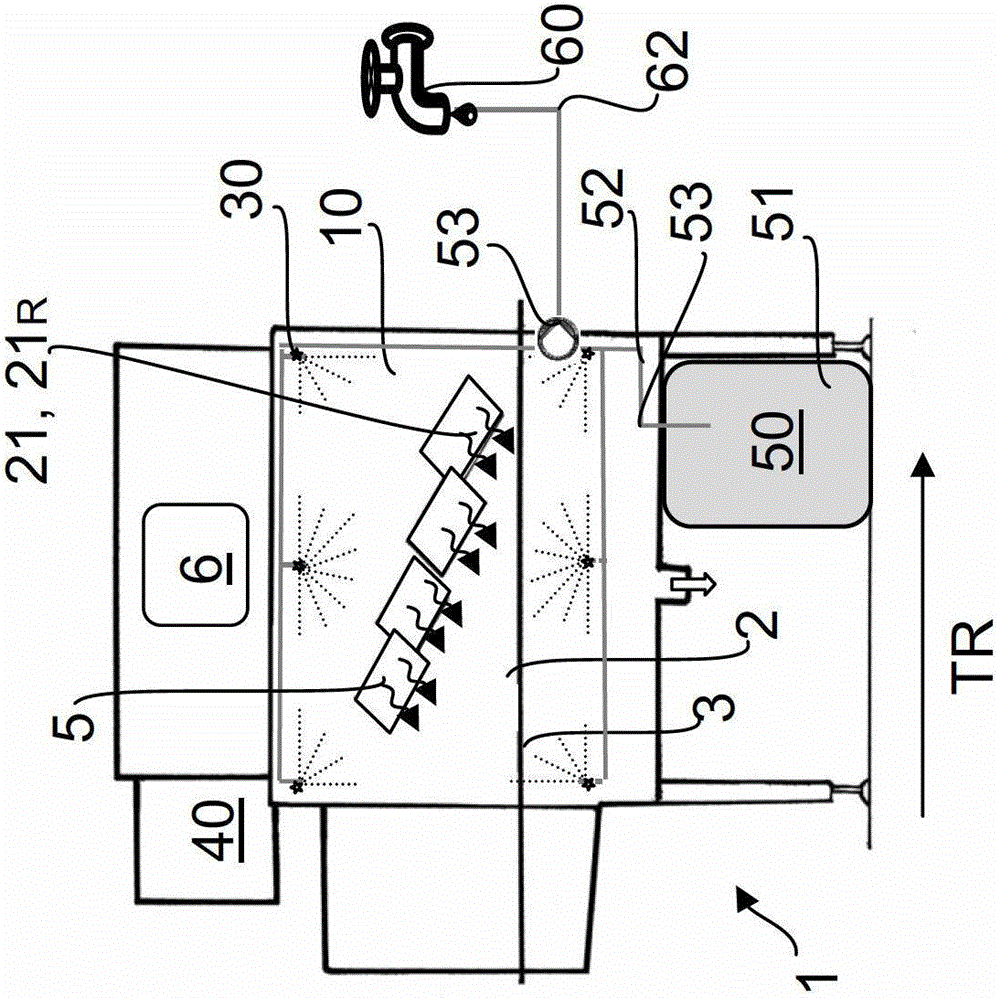

[0032] Figures 1 to 5 A view of a drying module 1 for bottles 2 according to the invention is shown in each case. The drying module 1 comprises a substantially closed drying chamber 10 with inlets and outlets 15 , 17 for the bottles 2 . The bottles 2 are transported vertically through the drying chamber 10 by means of the transport mechanism 3 . This is, for example, a transport channel in which the bottles 2 pass successively along the transport direction TR through the drying chamber 10 .

[0033] Above and / or next to the transport channel for the bottles 2 is arranged an air delivery system 4, for example dry air 20 is generated by a fan 6 and introduced via an air line 7 into the interior of the drying chamber 10, where the dry air 20 is located. The so-called air knife 5 is blown onto the bottle 2, preferably obliquely downwards. The blown-off moisture preferably collects in the outlet trough 9 which includes the outflow opening 9A. The discharge of the moist exhaust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com