Compressor and motor device thereof

A technology for compressors and motors, which is applied to electromechanical devices, parts of pumping devices for elastic fluids, mechanical equipment, etc., and can solve the problem that the gap between the rotor and the stator cannot be kept consistent.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

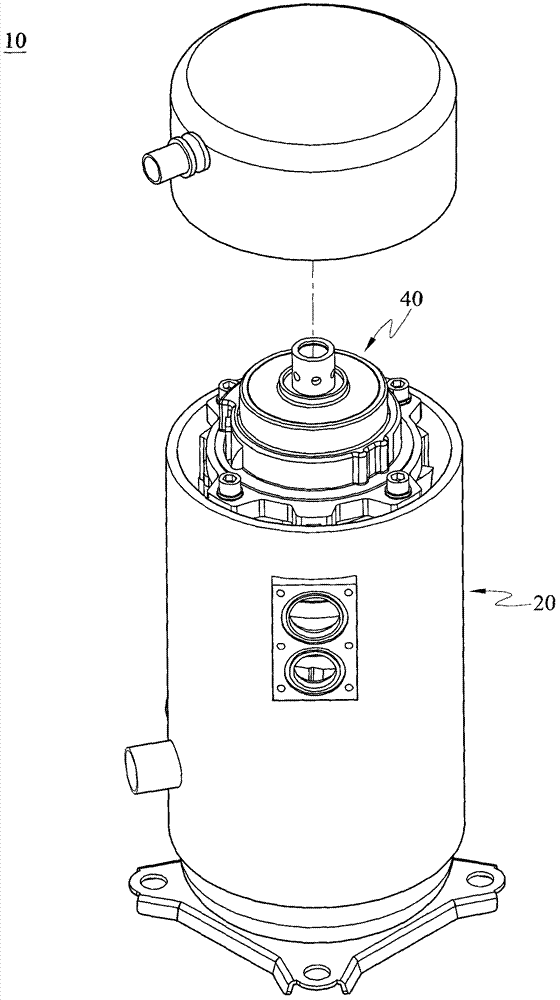

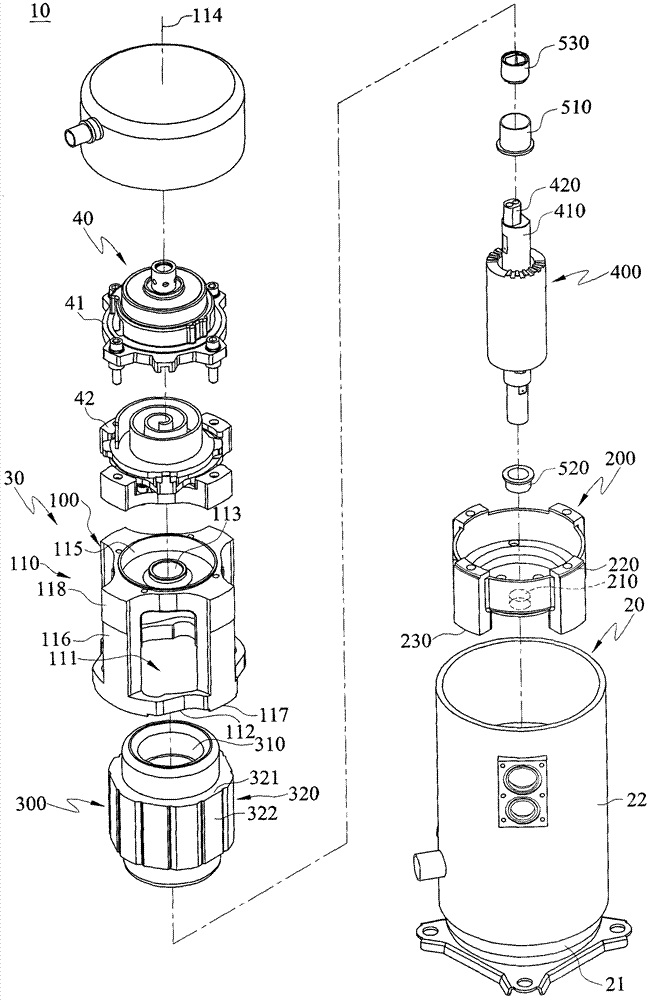

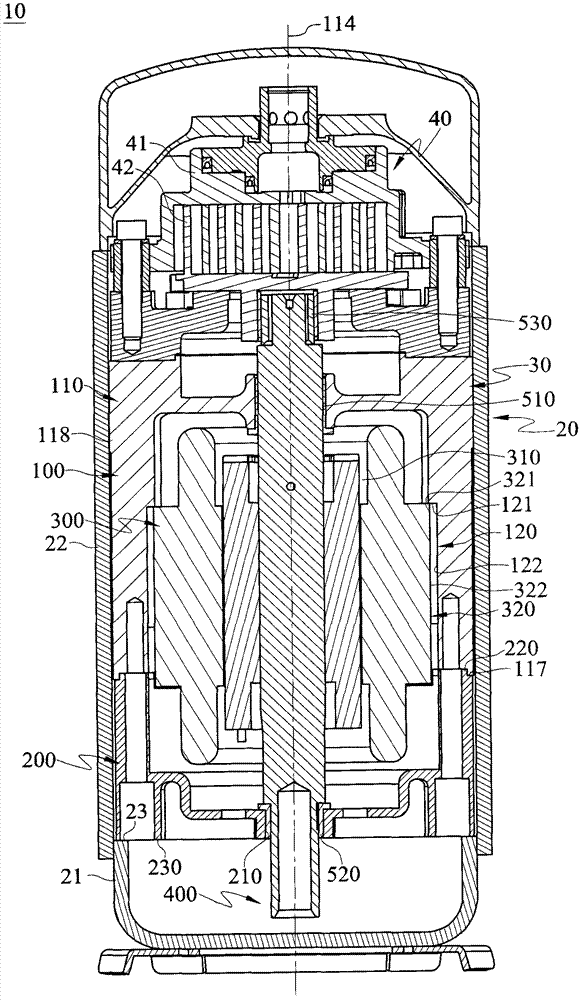

[0054] see Figure 1 to Figure 3B as shown, figure 1 is a three-dimensional schematic view of the compressor disclosed in the first embodiment, figure 2 for figure 1 The decomposition diagram of Figure 3A for figure 1 sectional schematic diagram of Figure 3B It is a schematic cross-sectional view of the compressor disclosed in the second embodiment. The above-mentioned compressor 10 is a scroll compressor.

[0055] The compressor 10 of this embodiment includes a casing 20 , a motor device 30 and a scroll member 40 . The motor device 30 is disposed in the casing 20 and includes a body 100 , an assembly 200 , a stator 300 and a rotor 400 .

[0056] The body 100 includes an assembly groove 110 and a plurality of first coupling parts 120 surrounding the inner wall of the assembly groove 110. In this embodiment, these fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com