Rear wheel of direct-current brushless permanent-magnet motor

A permanent magnet motor, DC brushless technology, applied in electrical components, electromechanical devices, magnetic circuit rotating parts, etc. The effect of reducing production costs and avoiding installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, further describe the technical solution of the present invention, but the present invention is not limited to these embodiments.

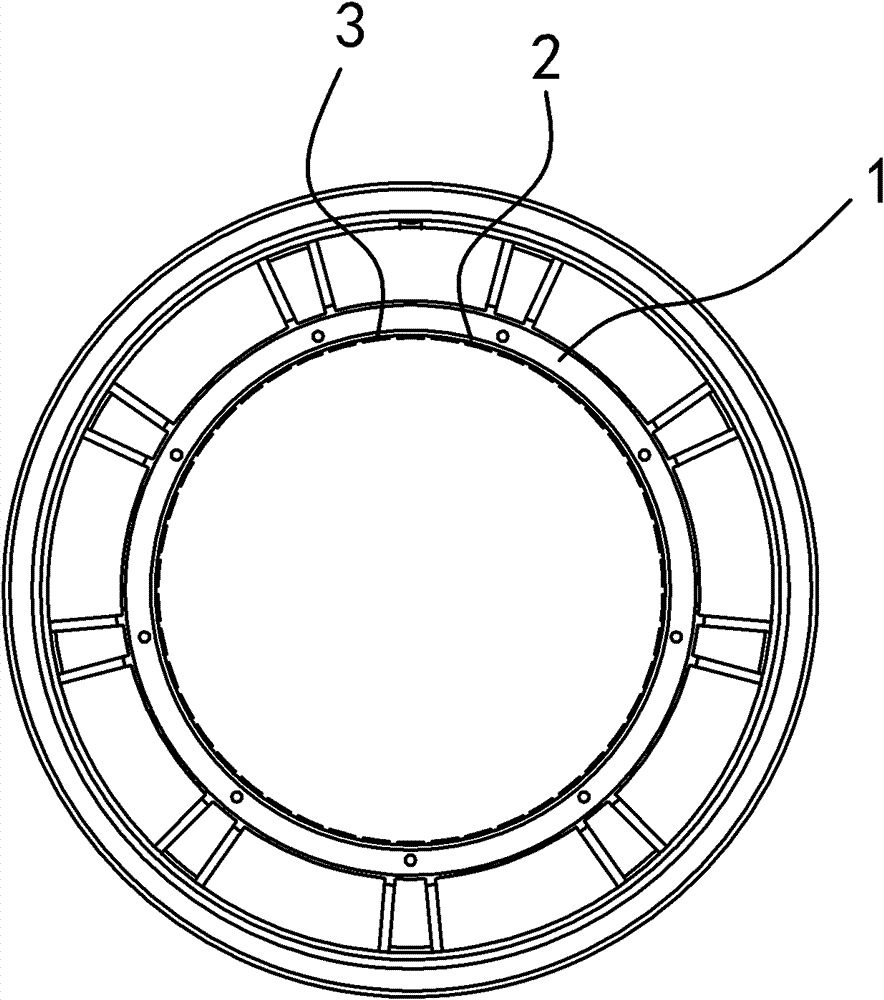

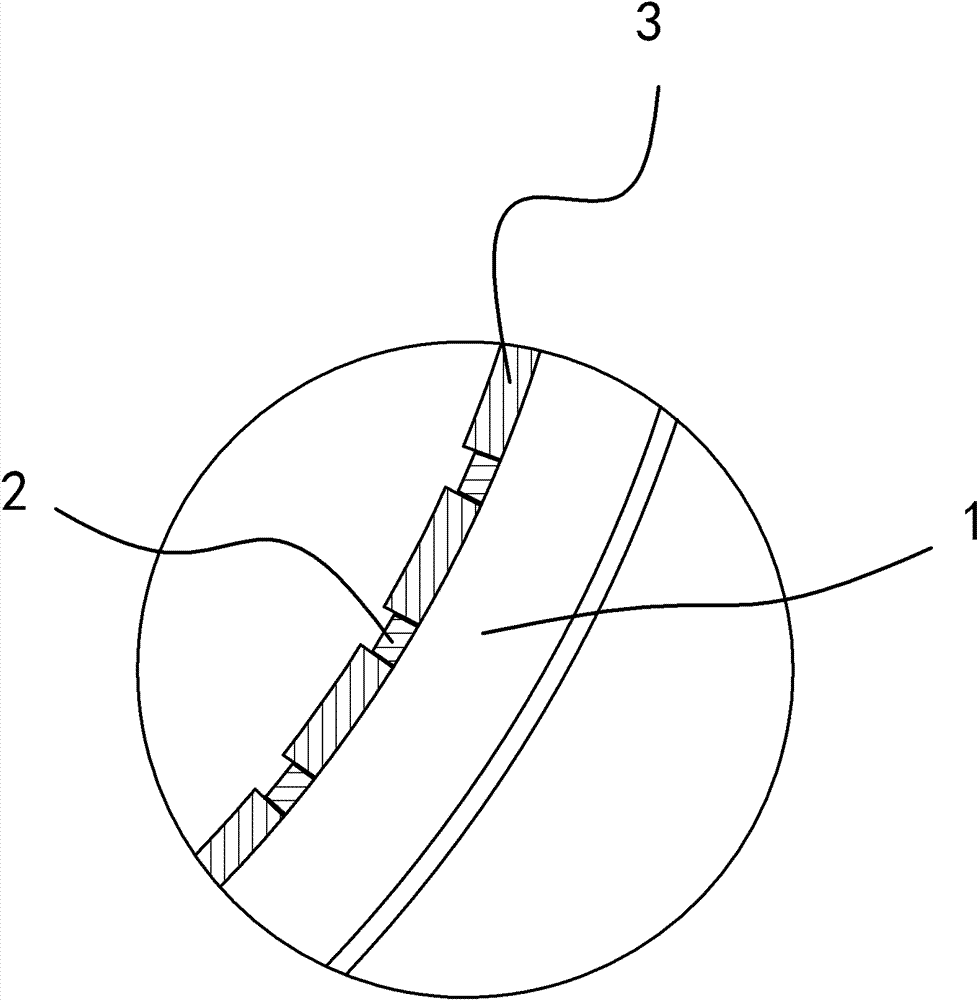

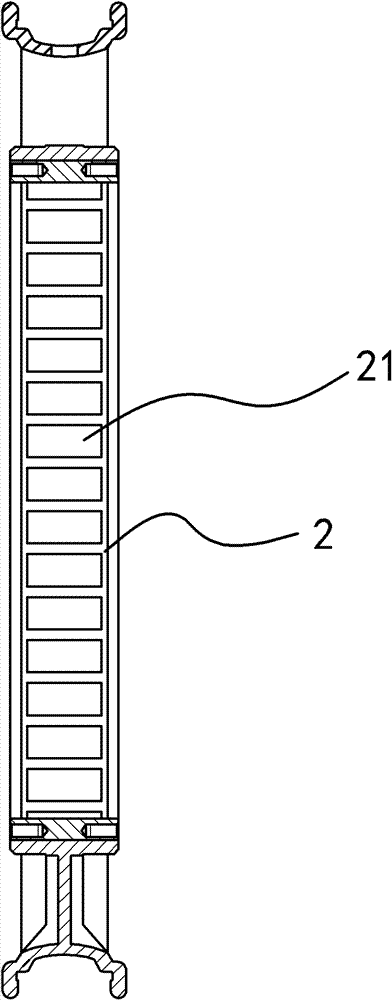

[0020] Such as figure 1 and figure 2 As shown, the rear wheel of this kind of DC brushless permanent magnet motor includes a hub 1, and a ring-shaped fixing strip 2 is fixedly connected to the inner ring of the hub 1 by glue, and the fixing strip 2 is made of a metal material. In this embodiment , The fixing bar 2 is made of steel material, which can not only ensure the strength of the fixing bar 2, but also be wear-resistant and corrosion-resistant, so as to improve the service life.

[0021] A plurality of evenly distributed mounting holes 21 are provided on the fixing bar 2, and a magnetic steel 3 is installed in each mounting hole 21, and there is a gap between two adjacent magnetic steels 3. The gaps are kept consistent,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com