Vibration absorption type downhole hydraulic pulse generation device and well drilling method thereof

A generating device and hydraulic pulse technology, applied in liquid/gas jet drilling, wellbore/well components, earthwork drilling and production, etc., can solve problems affecting drilling construction efficiency, affecting downhole tool performance, drill string fracture and damage, etc. Remarkable use effect, simple principle and structure, high drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

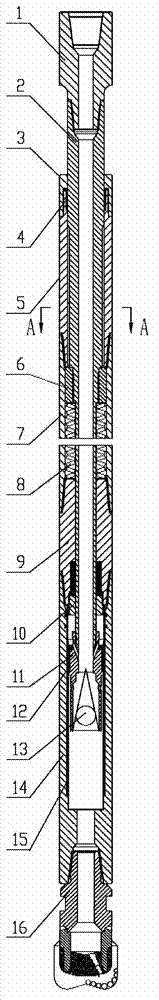

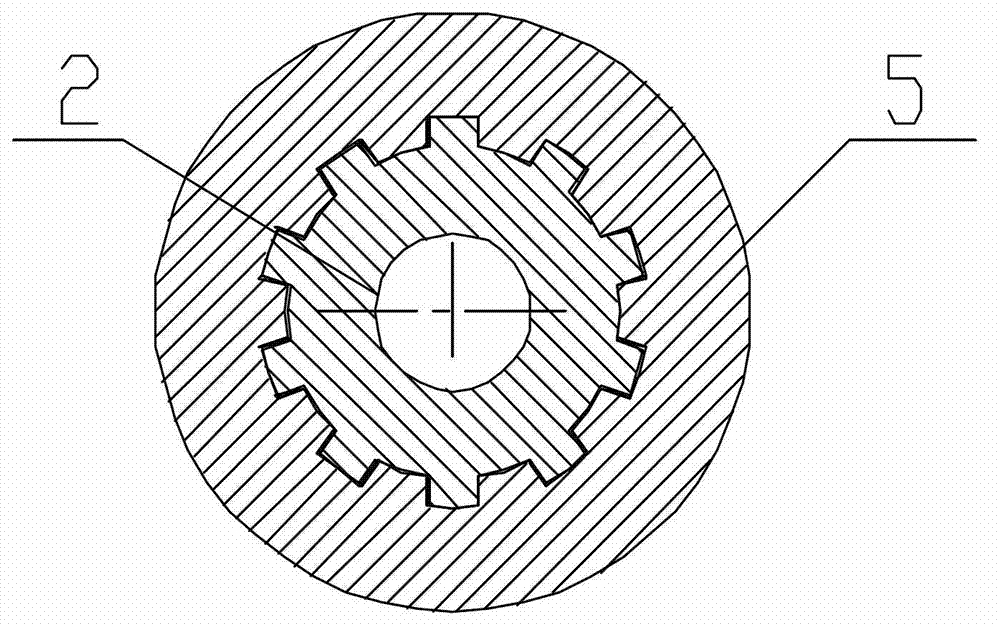

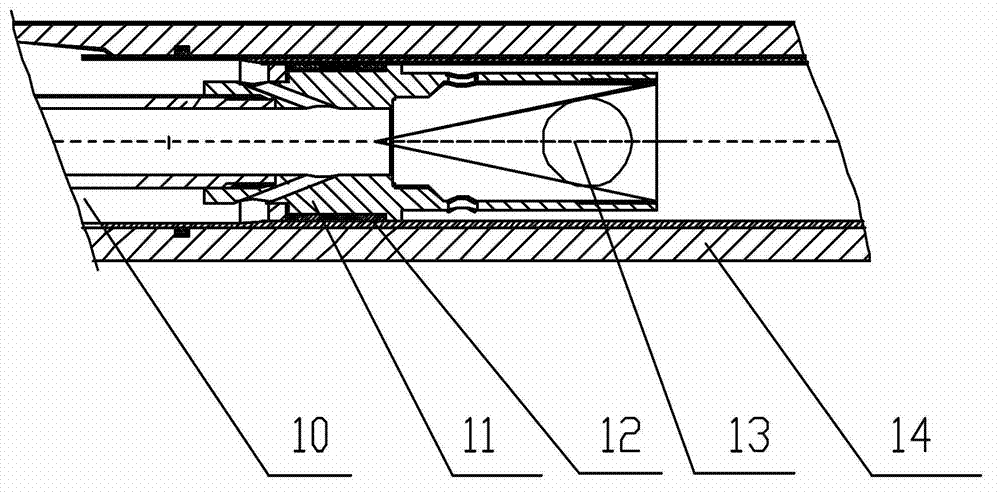

[0020] Specific embodiment one: as Figures 1 to 3 As shown, a vibration-absorbing downhole hydraulic pulse generating device, the device includes a drill string linkage body and a drill string transfer body, wherein the drill string linkage body includes a tool upper joint 1, a mandrel 2 and a sleeve set outside the middle of the mandrel 2 The limit body 6 of the drill string transfer body includes a plunger cylinder, a drill bit 16, a spline outer cylinder 5 set on the upper part of the mandrel 2 and a tool center joint 9 connected with the spline outer cylinder 5, and the plunger cylinder outer cylinder The bottom of 14 is connected with the drill bit 16, and the top is connected with the joint 9 in the tool; the plunger head 11 is installed inside the outer cylinder 14 of the plunger cylinder, and the plunger head 11 is connected with the upper joint 1 of the tool through the mandrel 2, and the plunger head 11 There is a diversion hole in the upper part of the plunger head...

specific Embodiment 2

[0033] Specific embodiment two: a kind of method that utilizes pulse jet to drill well, and its drilling step is: utilize the longitudinal vibration of drill string and the pressure-on-bit fluctuation, produce relative motion through the drilling linkage body of pulse generating device and drill string transfer body, make The relative motion generated by the internal plunger pump periodically compresses the drilling fluid in the plunger cylinder to generate pulsed jets, and uses the generated pulsed jets to improve the stress state at the bottom of the well and the effect of rock cleaning to increase the drilling speed and achieve rapid drilling .

[0034] The process of the pulse generator generating the pulse jet is as follows: when the drill string vibrates downward, that is, when the bit pressure increases, the drill string linkage body moves downward relative to the drill string transfer body, the volume in the plunger cylinder decreases, and the elastic reset The element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com