A method for extracting oleuropein from Qiaoling flower

An oleuropein and extraction technology, which is applied in the field of extracting high-purity oleuropein, can solve the problem of low oleuropein content, and achieve the effects of improving separation and purification efficiency, high yield, and convenient industrialized operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

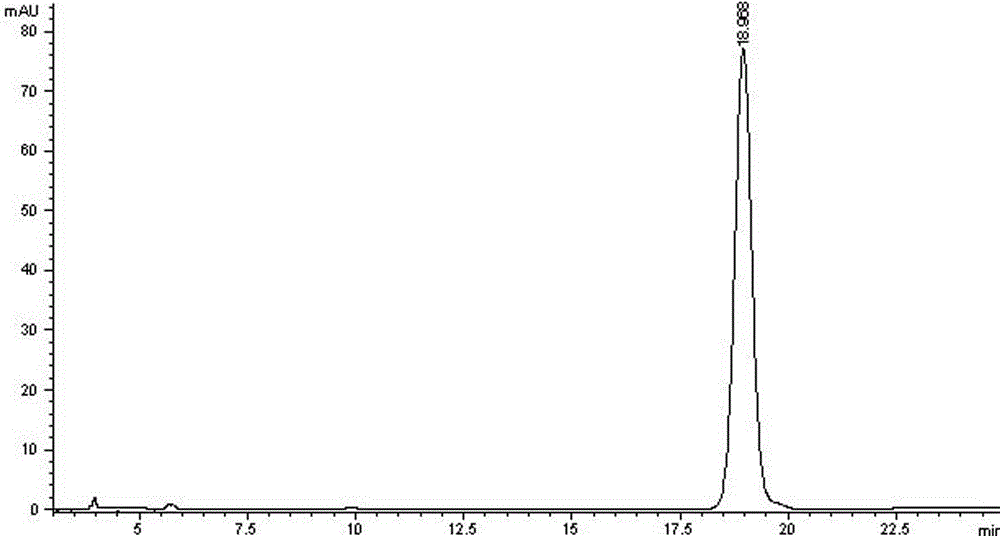

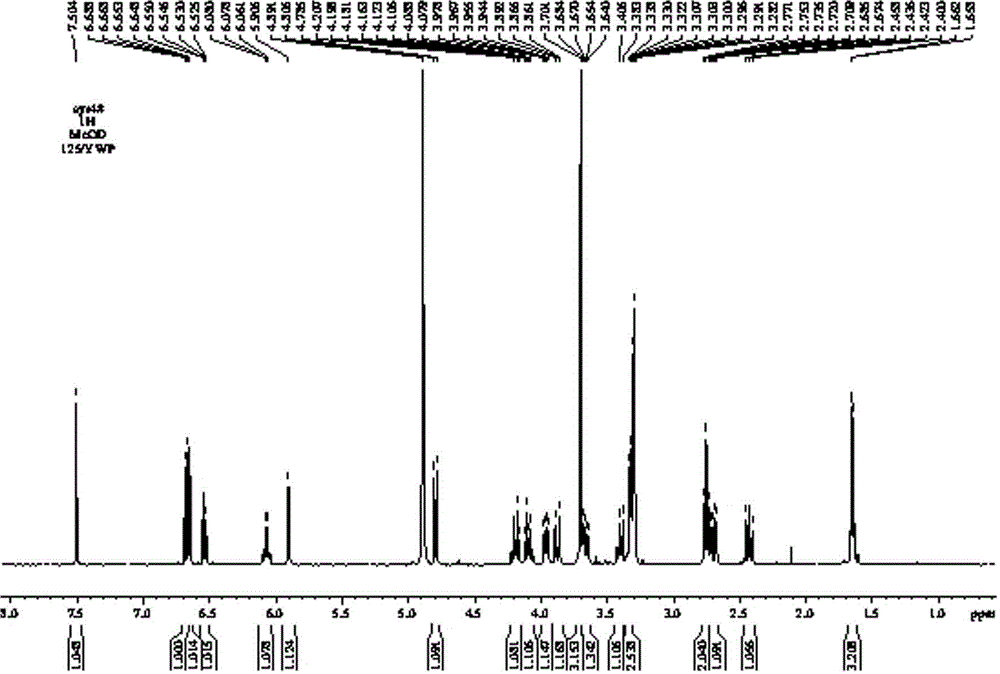

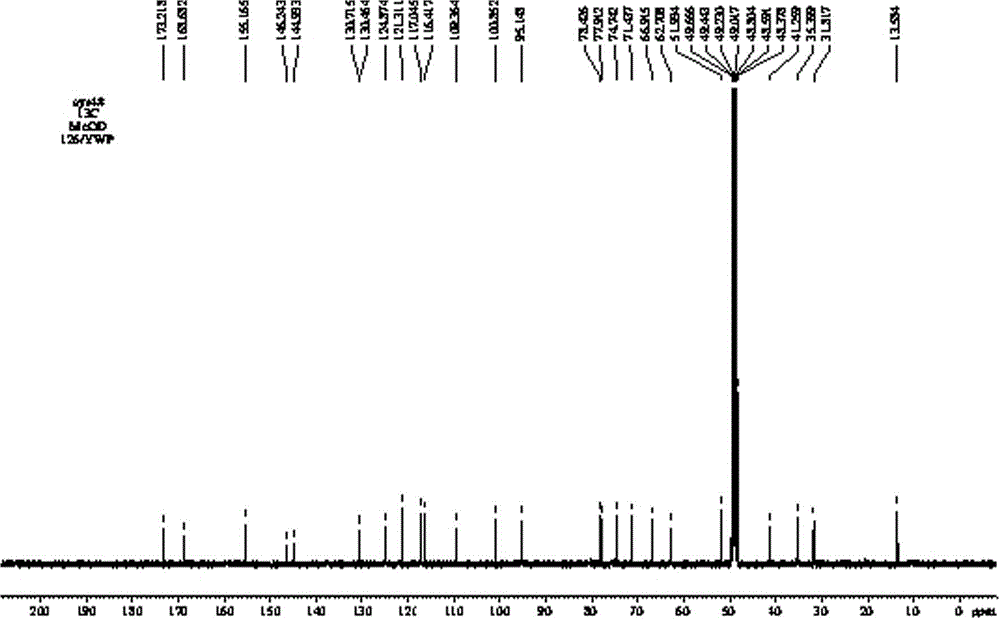

Image

Examples

Embodiment 1

[0039] A method for extracting oleuropein from Qiaolinghua, comprising the steps of soaking crushed dried Qiaolinghua in ethanol and then ultrasonically extracting, concentrating the extract into an extract, and purifying and separating the obtained extract ;

[0040] The method of ultrasonically extracting and concentrating Qiaolinghua after soaking is as follows: soak 1 kg of dried Qiaolinghua with a mass of 12 kg and 90% volume concentration of ethanol for 36 hours, and then ultrasonically extract 50% at 60°C. Minutes, filtered, repeated extraction of the filter residue 3 times, combined extracts, concentrated under reduced pressure distillation at 50-60°C, to obtain 210g of extract;

[0041] The step of described purification separation is:

[0042] Step 1: Dissolve 200g of the prepared extract with 7 times the mass of methanol, filter, mix the filtrate with silica gel-diatomaceous earth (mass ratio 1:1) with a mass multiple of 4 times the mass, evaporate the solvent and ...

Embodiment 2

[0046] A method for extracting oleuropein from Qiaolinghua, comprising the steps of soaking crushed dried Qiaolinghua in ethanol and then ultrasonically extracting, concentrating the extract into an extract, and purifying and separating the obtained extract ;

[0047] The method of ultrasonically extracting and concentrating Qiaolinghua after soaking is as follows: soak 1 kg of dried Qiaolinghua with a mass of 10 kilograms and 90% volume concentration of ethanol for 24 hours, and then ultrasonically extract it at 50°C for 30 Minutes, filtered, repeated extraction of the filter residue twice, combined extracts, concentrated under reduced pressure at 50-60°C to obtain 205 g of extract;

[0048] The step of described purification separation is:

[0049] Step 1: Dissolve the prepared 200g extract with 7 times the mass of acetonitrile, filter, mix the filtrate with silica gel-diatomaceous earth (mass ratio 2:1) with a mass multiple of 4 times the mass, evaporate the solvent and th...

Embodiment 3

[0053] A method for extracting oleuropein from Qiaolinghua, comprising the steps of soaking crushed dried Qiaolinghua in ethanol and then ultrasonically extracting, concentrating the extract into an extract, and purifying and separating the obtained extract ;

[0054] The method of ultrasonically extracting and concentrating Qiaolinghua after soaking is as follows: 3 kg of crushed dried Qiaolinghua is soaked in 30 kg of ethanol with a volume concentration of 90% for 24 hours, and then ultrasonically extracted at 60°C for 30 Minutes, filtered, repeated extraction of the filter residue 3 times, combined extracts, concentrated under reduced pressure distillation at 50-60°C, to obtain 708g of extract;

[0055] The step of described purification separation is:

[0056] Step 1: Dissolve the prepared 700g extract with 5 times the mass of methanol, filter, mix the filtrate with silica gel-diatomaceous earth (mass ratio 1:2) with a mass multiple of 4 times the mass, and evaporate the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com