Desulfurization gypsum concrete

A technology of desulfurized gypsum and desulfurized building gypsum, which is applied in the field of desulfurized gypsum concrete, can solve the problems of waste of support materials, slow setting time, and low flexural strength, and achieve reduced construction period, fast curing time, shear resistance and The effect of improving cracking ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

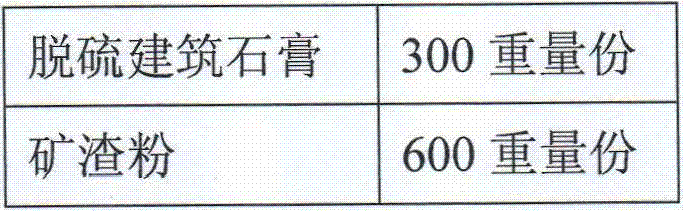

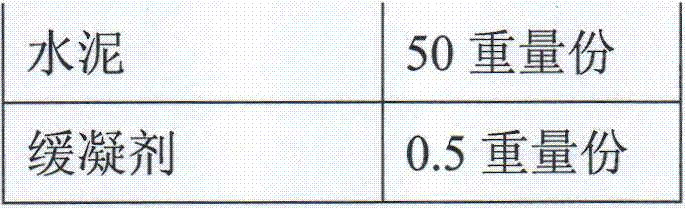

[0070] 1. Masterbatch formula

[0071] Table 1

[0072]

[0073]

[0074] Mix the masterbatch according to the above formula, and stir evenly. Test its performance, the test data is as follows:

[0075] Table 2

[0076] performance parameters

Test Results

14 days flexural strength / Mpa

GB / T17671-1999

5.7

14 days compressive strength / Mpa

GB / T17671-1999

26.1

compressive strength softening factor

0.86

[0077] 2. Preparation of desulfurized gypsum concrete

[0078] Mix the masterbatch, medium sand, melon seeds with a fineness modulus greater than 2.5, and water at a volume ratio of 1:1.5:1.5:0.4, and stir evenly.

[0079] The performance test of the prepared gypsum sprayed concrete is carried out, and the test data are as follows:

[0080] table 3

[0081] performance parameters

Embodiment 2

[0083] 1. Masterbatch formula

[0084] Table 4

[0085] Desulfurization building gypsum

600 parts by weight

300 parts by weight

cement

100 parts by weight

[0086] alum

0.2 parts by weight

1.5 parts by weight

0.5 parts by weight

VAC / VeoVa copolymerized redispersible latex powder

1 part by weight

1 part by weight

[0087] Mix the masterbatch according to the above formula, and stir evenly. Test its performance, the test data is as follows:

[0088] table 5

[0089] performance parameters

Test Results

14 days flexural strength / Mpa

GB / T17671-1999

6.4

14 days compressive strength / Mpa

GB / T17671-1999

28.3

compressive strength softening factor

0.89

[0090] 2. Preparation of desulfurized gypsum concrete

[0091] Mix the masterbatch, medium san...

Embodiment 3

[0096] 1. Masterbatch formula

[0097] Table 7

[0098] Desulfurization building gypsum

[0099] Mix the masterbatch according to the above formula, and stir evenly. Test its performance, the test data is as follows:

[0100] Table 8

[0101] performance parameters

[0102] 2. Preparation of desulfurized gypsum concrete

[0103] Mix the masterbatch, medium sand, melon seeds with a fineness modulus greater than 2.5, and water at a volume ratio of 1:1.5:1.5:0.36, and stir evenly.

[0104] The performance test of the prepared gypsum sprayed concrete is carried out, and the test data are as follows:

[0105] Table 9

[0106] performance parameters

[0107] 28-day standard curing axial compressive strength standard value / Mpa

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com