Lifting ring assembling device

An assembly device and ring-dividing technology, which is applied in packaging and other directions, can solve problems such as high requirements for lifting rings, inability to hang bottles, and small application range, etc., to achieve the expansion of application range, reduce the incidence of work-related injuries, and reduce the requirements for shape and placement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

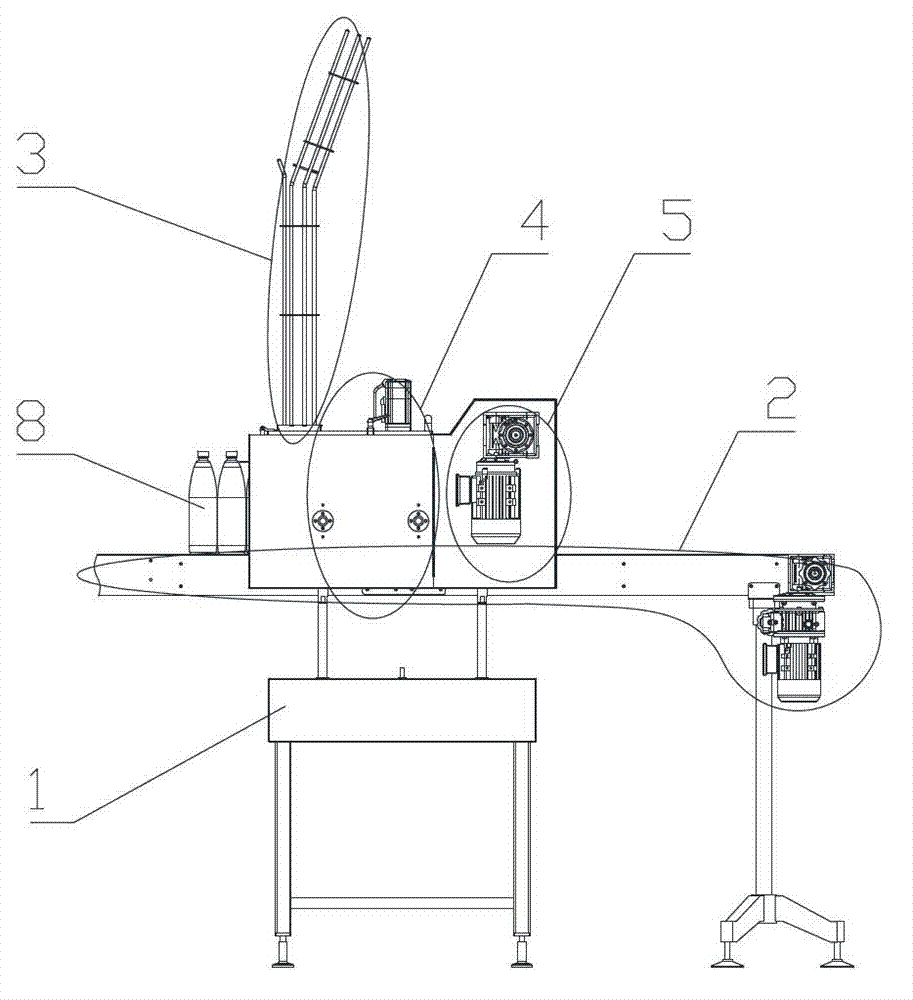

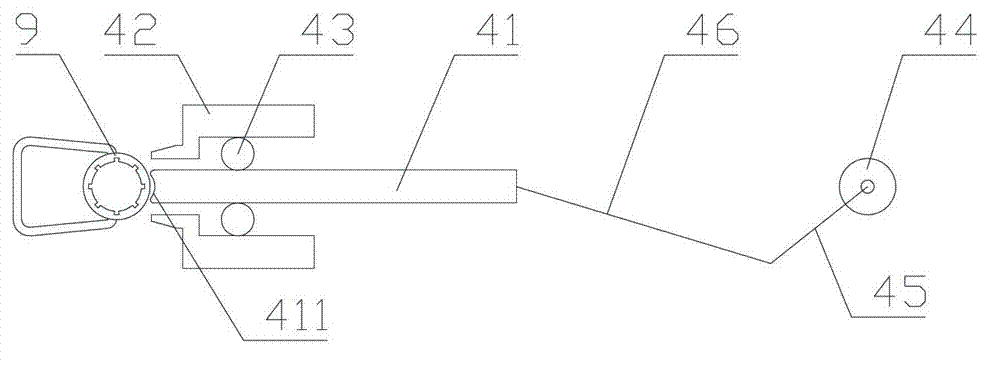

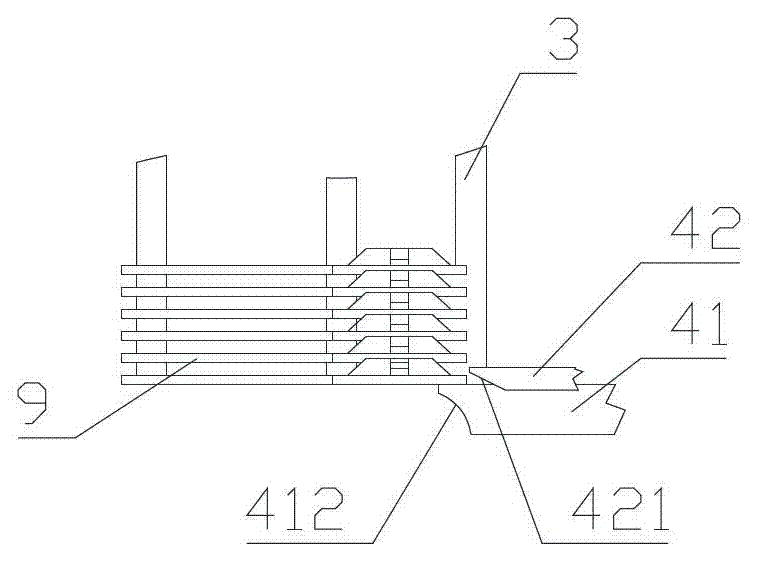

[0024] Such as figure 1 Shown is the first embodiment of the present invention, a lifting ring assembly device, including a frame 1 and a conveying part 2, a material storage part 3, a sub-ring part 4 and a ring pressing part 5 arranged on the frame 1. The material storage part 3, the sub-ring part 4 and the pressure ring part 5 are arranged sequentially from front to back along the conveying direction of the bottle 8, and the material storage part 3, the sub-ring part 4 and the pressure ring part 5 are arranged on the conveying part 2 above, the sub-ring part 4 corresponds to the lower part of the storage part 3 . The conveying part 2 is used to transport the bottle 8, the storage part 3 is used to store the lifting ring 9, the sub-ring part 4 separates the lifting ring 9 from the storage part 3 so that the lifting ring 9 falls on the bottle 8, and the pressing ring part 5 is used for Then press the fastening portion of the lifting ring 9 onto the bottle 8 and assemble it. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com