Automatic assembly of lamp base and energy-saving lamp using the lamp base

An automatic assembly and lamp cap technology, which is applied to the parts of gas discharge lamps, discharge lamps, discharge tubes, etc., can solve the problems of inability to realize automatic mechanical assembly, relying on labor, and single connection method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The automatic assembly lamp cap and the energy-saving lamp using the automatic assembly lamp cap of the present invention will be further described in detail below with reference to the drawings and specific embodiments.

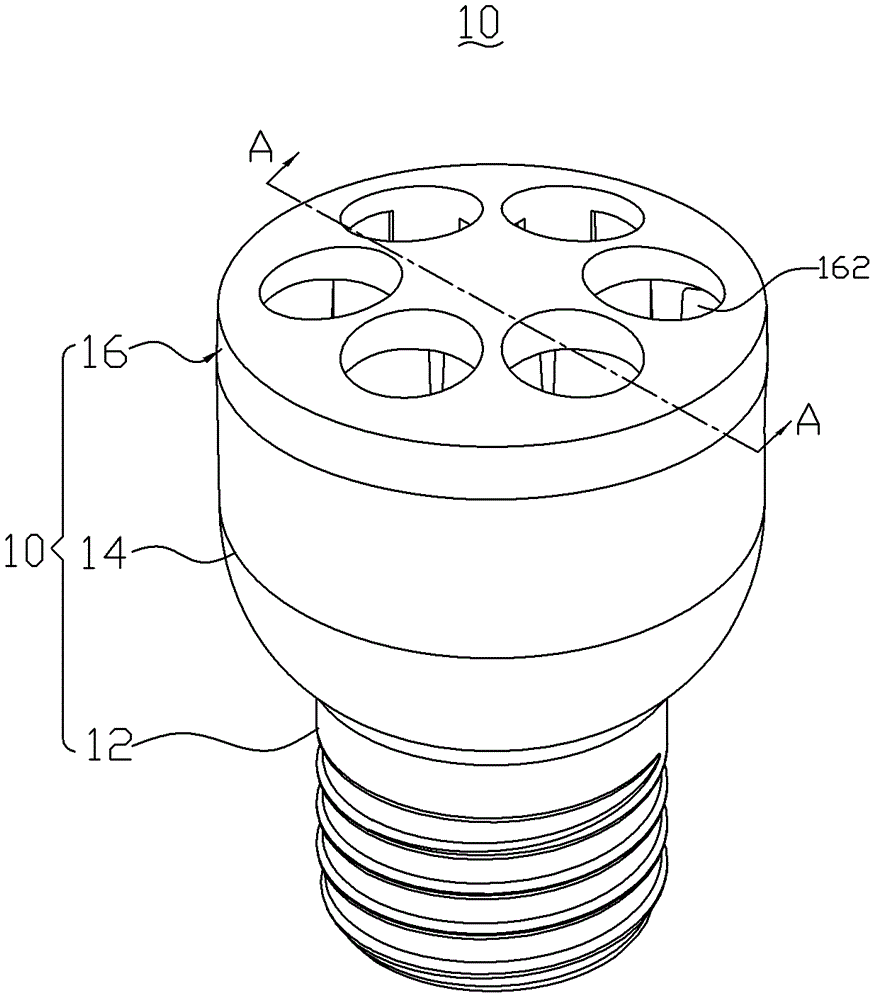

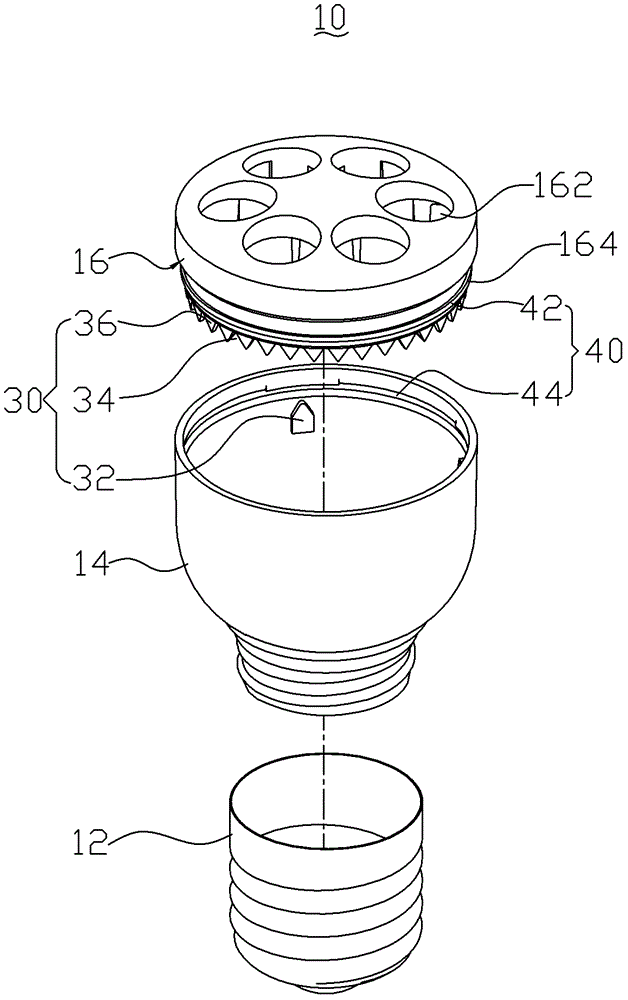

[0016] Please refer to figure 1 , The automatic assembly lamp cap 10 of the present invention comprises a lamp cap 12 , a lamp cup 14 and a mounting base 16 , the mounting base 16 , the lamp cup 14 and the lamp cap 12 are connected from top to bottom to form the lamp cap 10 . The mounting base 16 is a shell structure with a “door” shape in cross-section. The top of the mounting base 16 is provided with six mounting holes 162 , and the bottom of the mounting base 16 is provided with an annular connecting portion 164 .

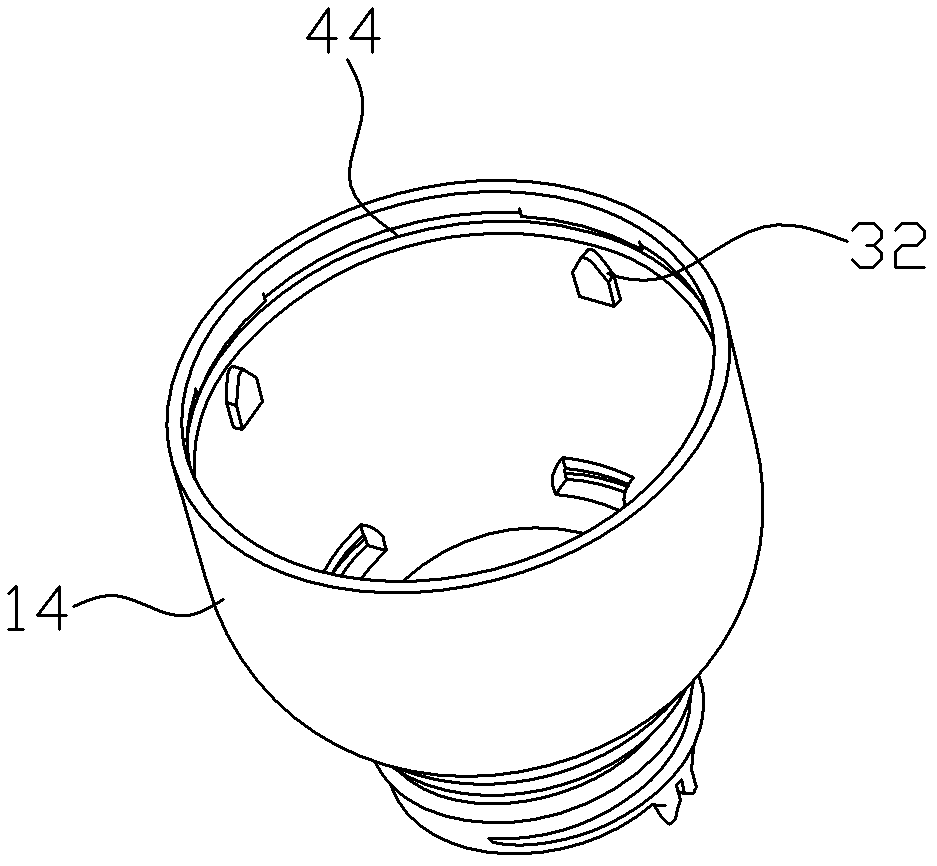

[0017] combine Figure 2 to Figure 6 As shown, the lamp cup 14 is a hollow cylindrical shell structure, and the lamp base 12 is connected to the bottom of the lamp cup 14 through threads. The lamp cup 14 is connected and fixed to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com