Belt buckle buckle head pressing machine

A belt and equipment technology, applied in the field of belt buckle processing equipment, can solve problems such as high labor costs and long working hours, and achieve the effects of improving production quality, improving production efficiency and high profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

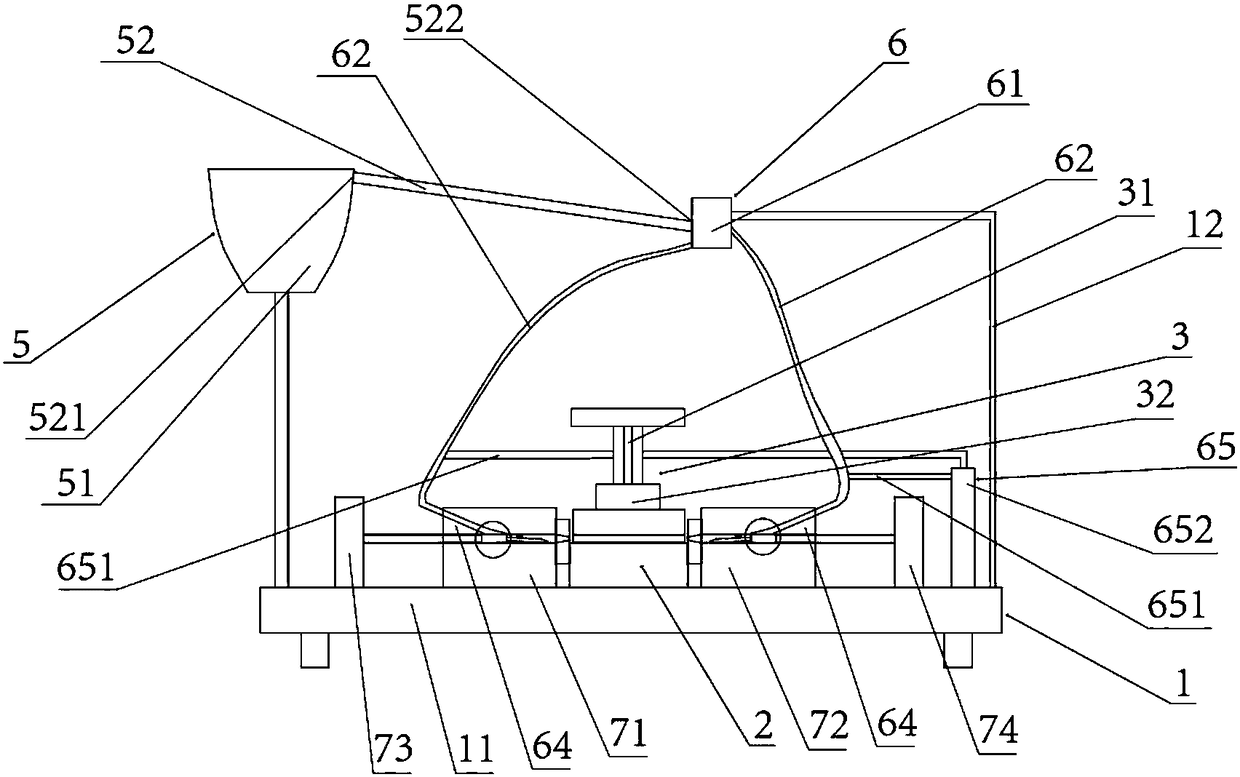

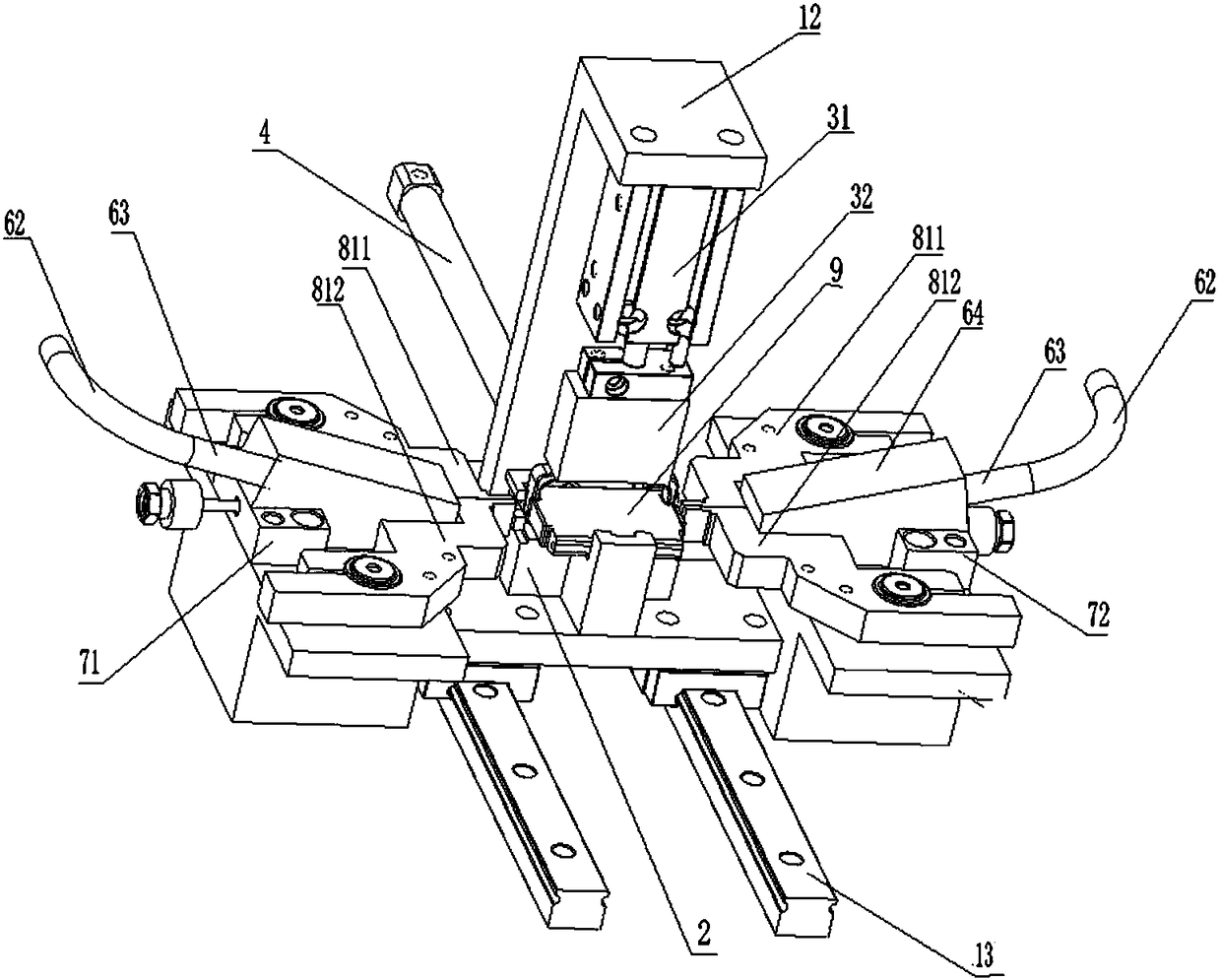

[0045] The present invention will be further elaborated below in conjunction with accompanying drawing, wherein, the direction of the present invention is with figure 1 as standard.

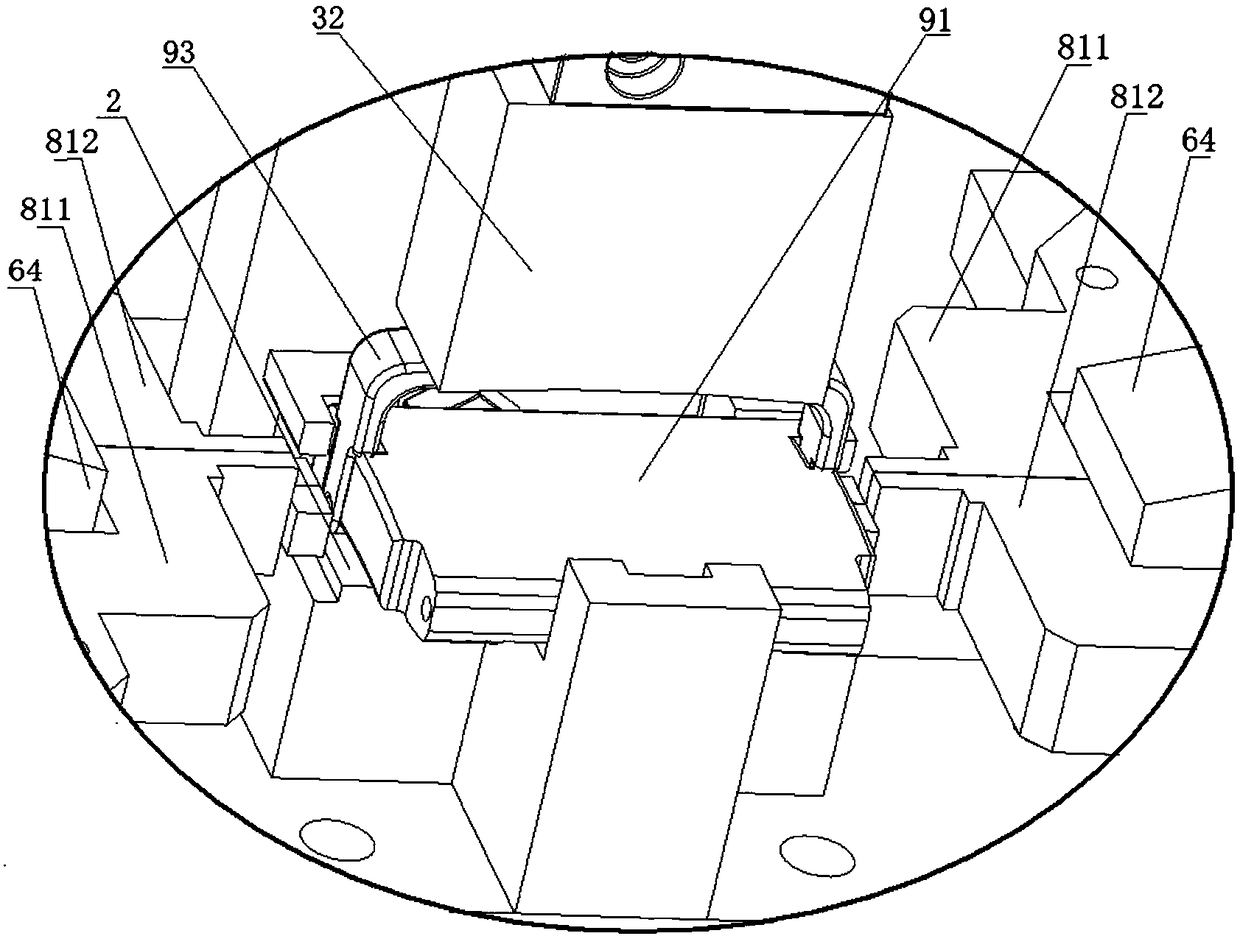

[0046] Such as Figure 1 to Figure 22 As shown, the belt buckle buckle head nail pressing device of the present invention includes a frame 1, a mold cavity 2, a pressing assembly 3, an expansion member, a nail row assembly 5, a nail feeding assembly 6, a nail pressing assembly 7, and a rivet positioning assembly 8 and buckle head 9, buckle head 9 comprises main board 91, teeth boy 92, meson 93 and rivet 94, wherein:

[0047] Frame 1 adopts the frame type structure of prior art, and frame 1 is provided with main frame 11 and side frame 12, and the table top of main frame 11 is provided with two slide rails 13 in parallel at intervals.

[0048] The mold groove 2 is used to place the buckle head 9 and assemble the main board 91, the teeth 92 and the meson 93 of the buckle head 9 together. The mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com