Vapor generator primary side baffle operation robot

A technology of robot and mechanical arm, which is applied in the field of steam generator primary side blocking plate operation robot, which can solve the problems of increasing the time of operators in contact with the nuclear environment, affecting the health status of operators, prolonging the time for overhaul of nuclear power plants, etc., and shortening the overhaul time, avoid inconsistent bolt tightening degree, and reduce work effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical scheme of the present invention will be described in detail below in conjunction with the accompanying drawings.

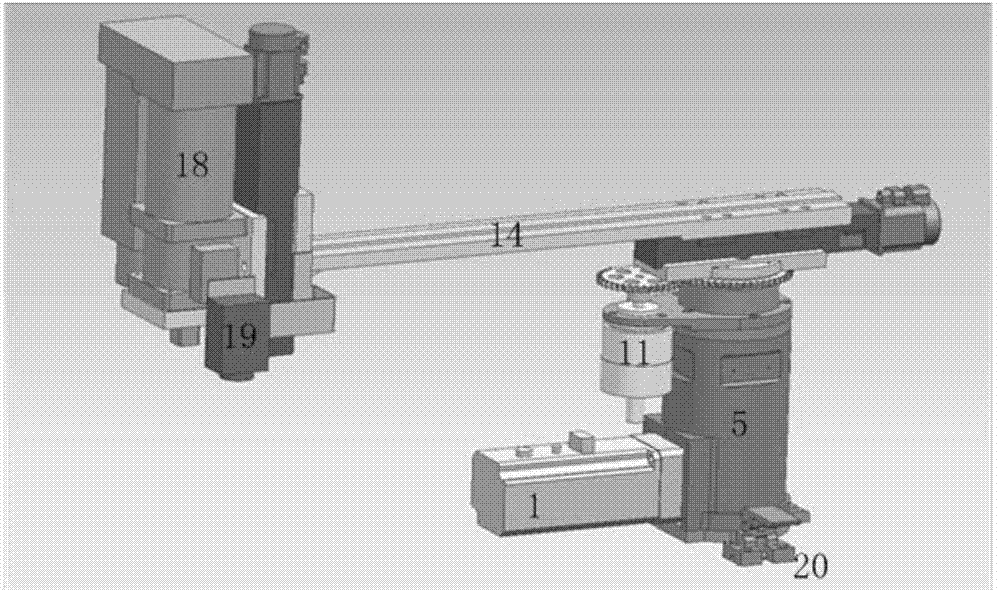

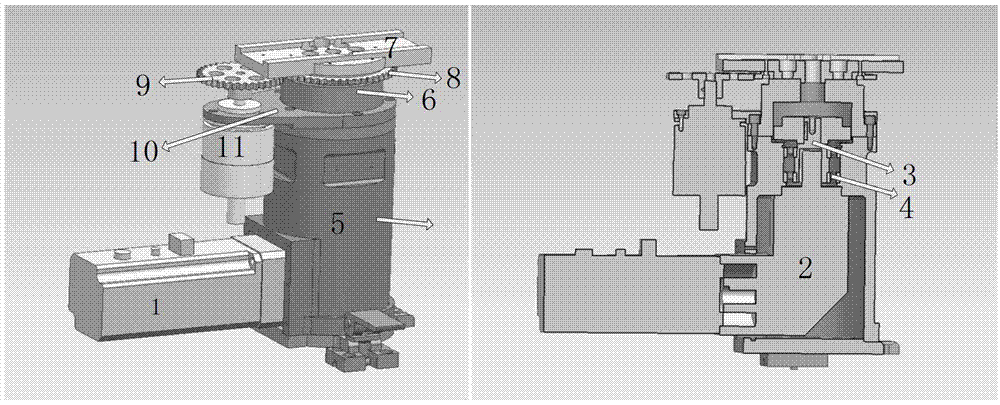

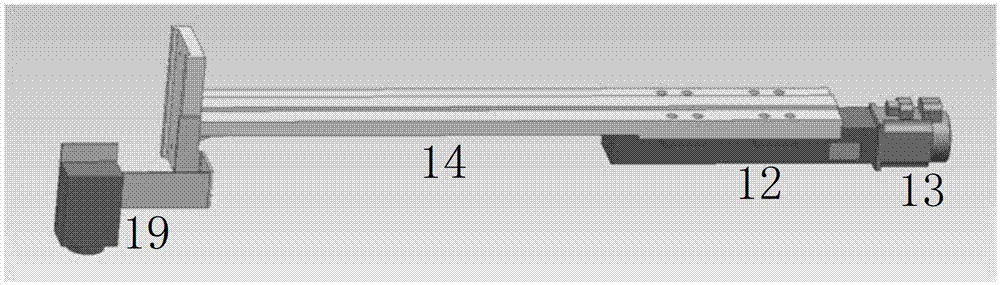

[0040] Such as figure 1 As shown, the steam generator primary side blocking plate operation robot according to the present invention consists of three parts: a rotating part, a radially telescopic part and an end lifting part.

[0041]The steam generator primary side blocking plate operation robot adopts a typical cylindrical coordinate system design, which has the advantages of simple and compact structure, convenient operation, small volume, light weight, and easy moving and clamping. Its overall structure is divided into three parts: the rotating part, the radial expansion part and the end lifting part. The three parts cooperate with each other and coordinate the control to realize the tightening and loosening of the bolts on the blocking plate at the primary side cold and hot ports of the steam generator to prevent During an overhaul of a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com