Axial and lateral scale scraping auxiliary mechanism

An auxiliary mechanism and scale-scraping technology, used in slaughtering, fish processing, food science, etc., can solve problems such as low efficiency and difficult operation, and achieve the effect of ensuring straightness, convenient rotation of the fish body, and enhanced bending rigidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

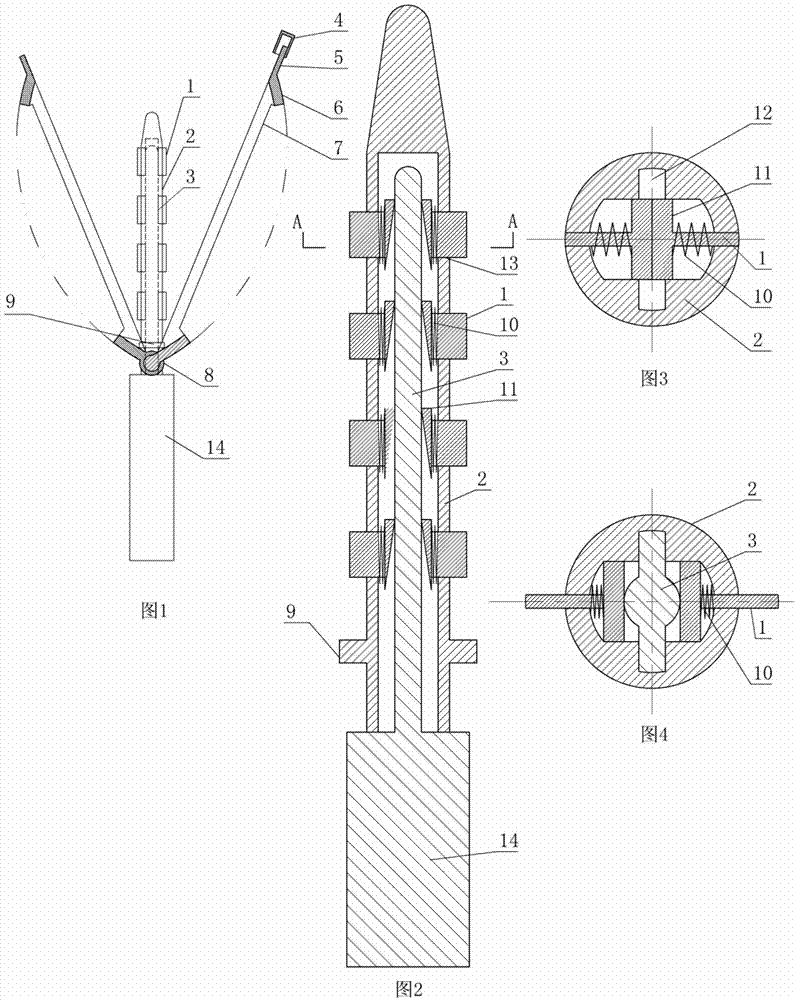

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] The axial and lateral scale scraping auxiliary mechanism consists of fixed wing 1, fixed cylinder 2, stretching rod 3, locking cap 4, locking rod 5, splint 6, scraping window 7, hinge 8, non-return ring 9, Spring 10, guide block 11, positioning groove 12, expansion joint 13 and handle 14 constitute. Wherein, the splint 6 is a pair of shells with an oval profile and a curved surface, and the lower ends of the two splints 6 are connected by a hinge 8 and can be freely separated and closed. At the top of the splint 6, there is a locking rod 5 integral with the splint 6. The locking rod 5 is a screw rod with a semicircular cross section. When the two splints 6 are closed, the two locking rods 5 merge. into a complete cylindrical screw. The inner surface of the locking cap 4 is threaded, and the locking cap 4 is screwed on the locking rod 5 .

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com