Electric brake

A brake, electric technology, applied in the direction of brake type, brake actuator, engine, etc., to achieve the effect of low reduction ratio, reduced position requirements and cost, simple and reliable force introduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

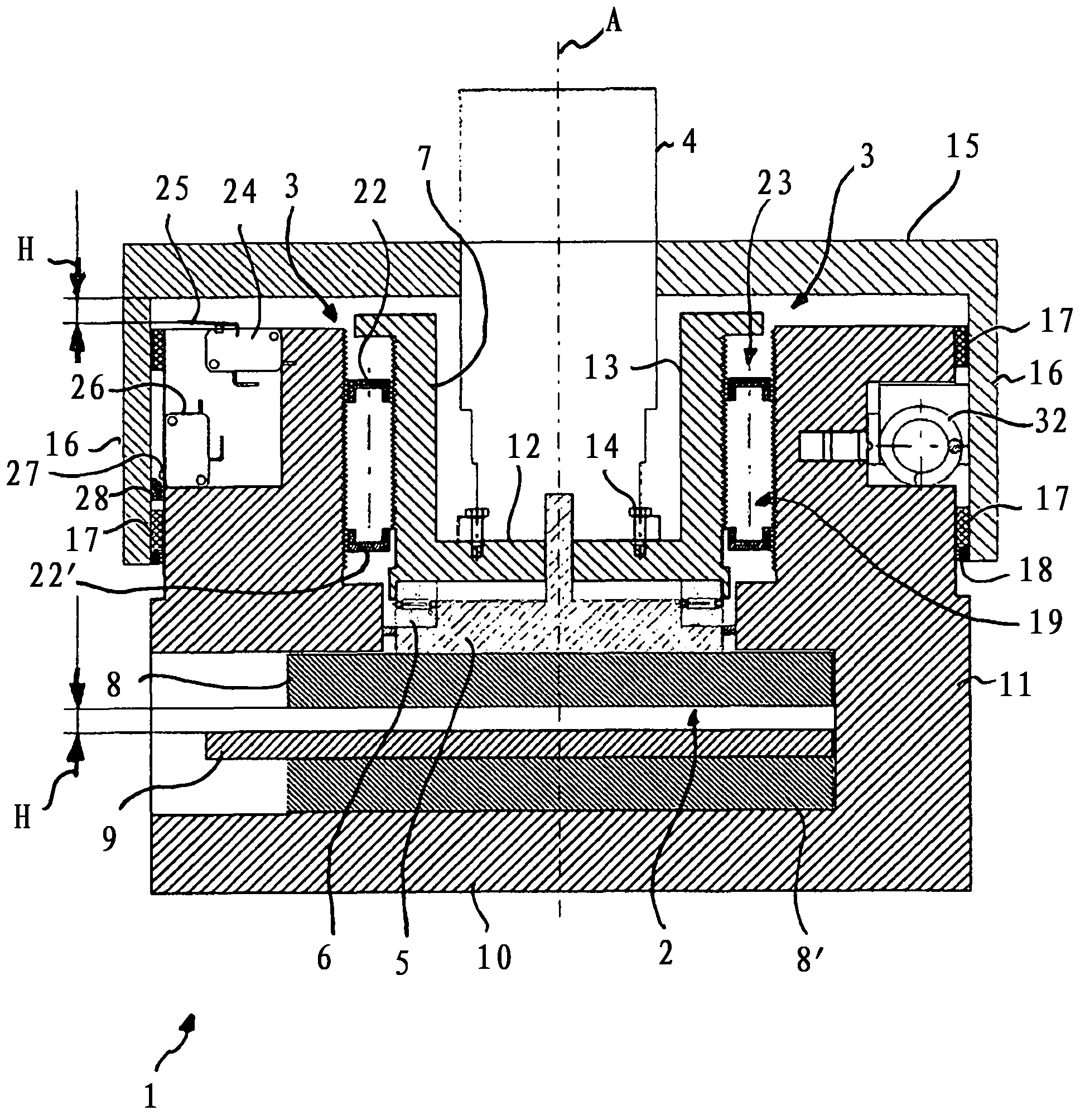

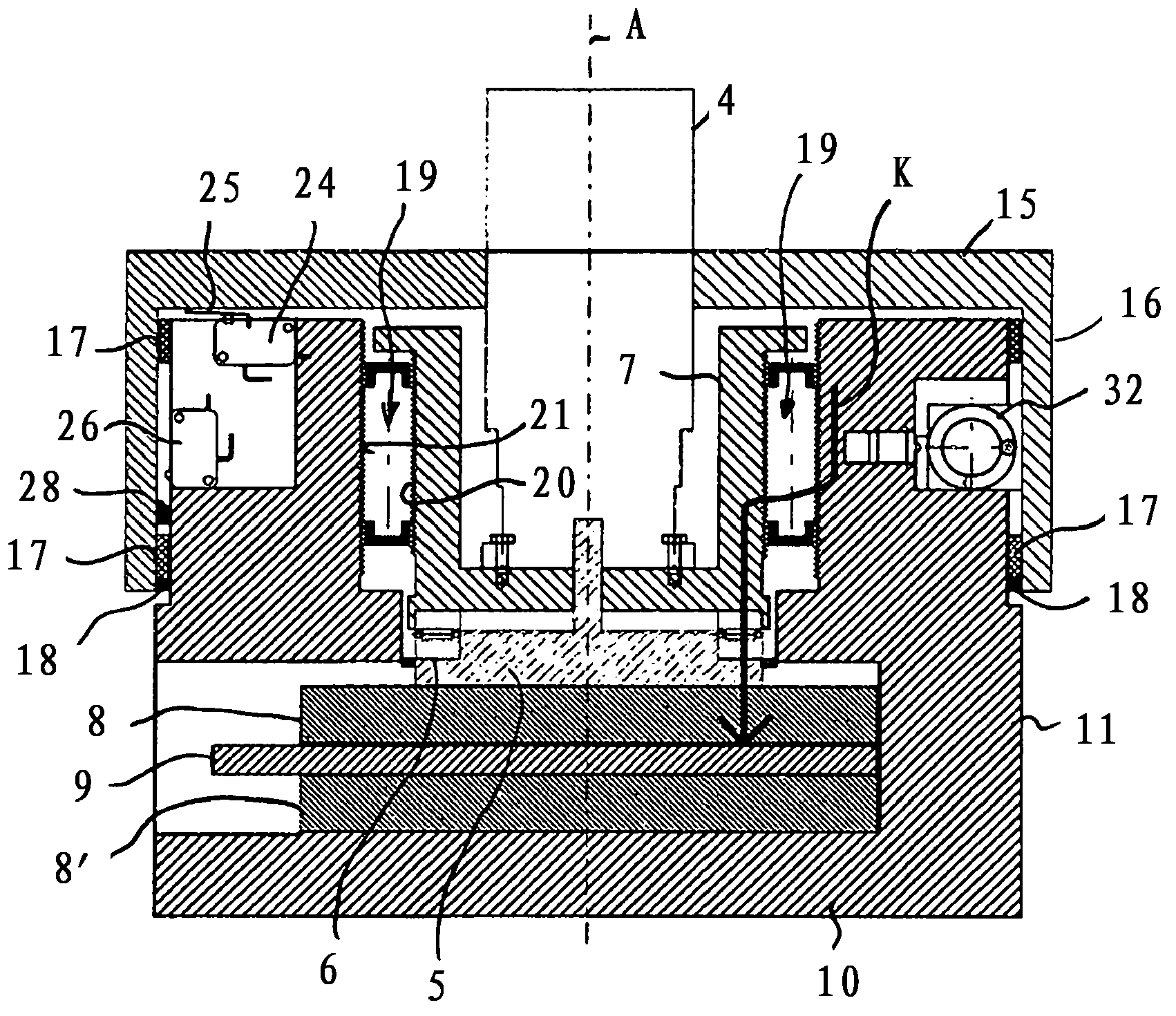

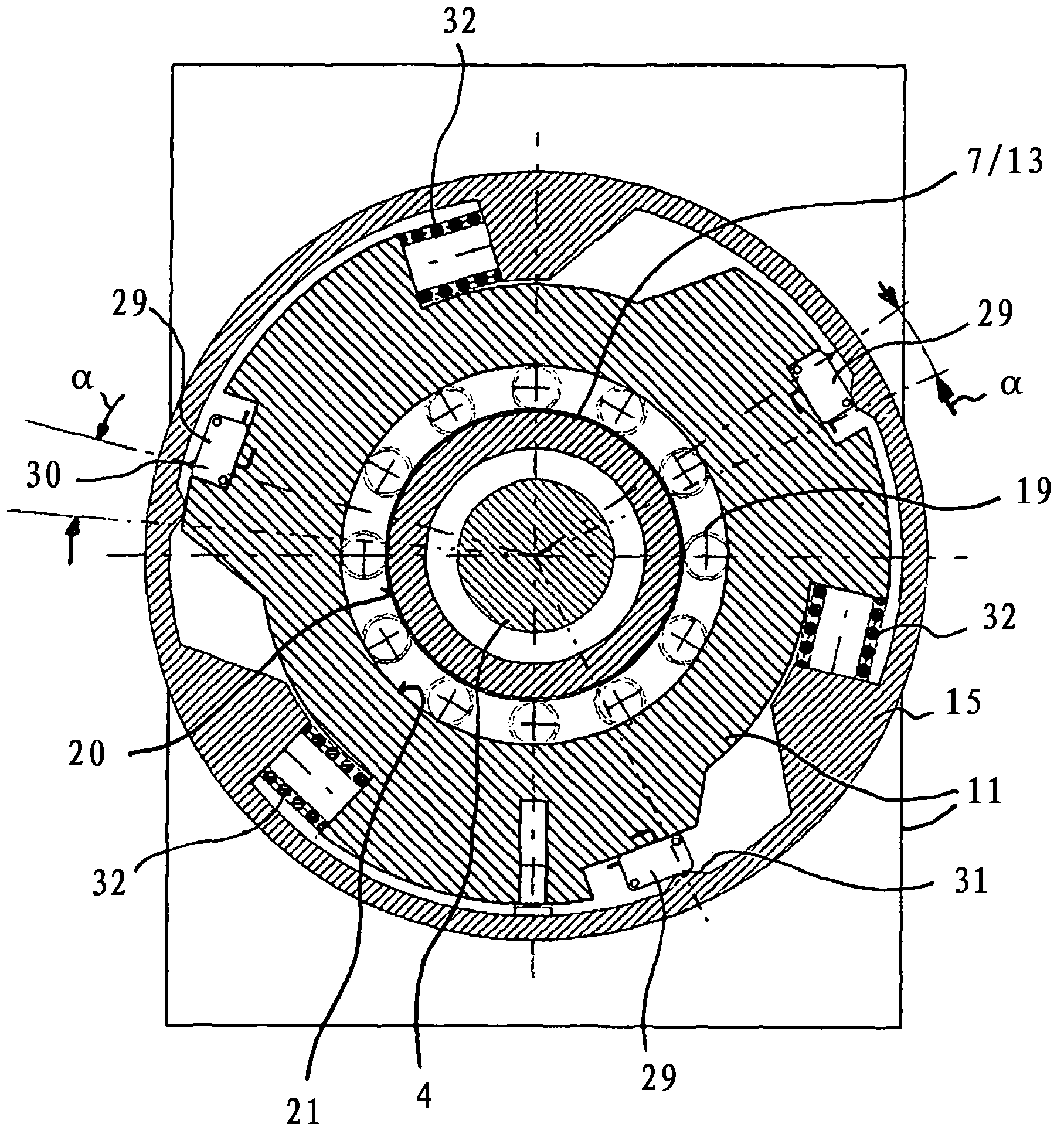

[0023] The brake 1 according to the invention can preferably be used in a wind power plant for braking a rotor blade. Alternatively, the brake 1 can also be used in a braking system for a sun-tracking device or in a braking system in the field of mechanical engineering or medical technology.

[0024] Brake 1 essentially has a brake actuating element 2 (brake shoe), a planetary roller screw unit 3 coupled to brake actuating element 2 , and an electric drive 4 coupled to planetary roller screw unit 3 .

[0025] The brake actuating element 2 has on the one hand a holding disk 5 which is coupled to a bell-shaped spindle element 7 via an axial bearing 6 designed as a needle bearing. On the other hand, the holding disc 5 of the brake operating element 2 has a brake lining 8 on the side facing away from the spindle element 7 , which brake lining 8 when the brake 1 is actuated, that is to say in the axial direction of the brake operating element 2 . When exercising by figure 1 The n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com