Compound type high-voltage direct current transmission system

A high-voltage direct current, power transmission system technology, applied in the direction of power transmission AC network, etc., can solve the problems of being unsuitable for temporary fault power overhead lines, not having the ability to handle DC faults, and unable to adopt fault restart methods, etc., to achieve high reliability , reasonable design and flexible operation mode

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

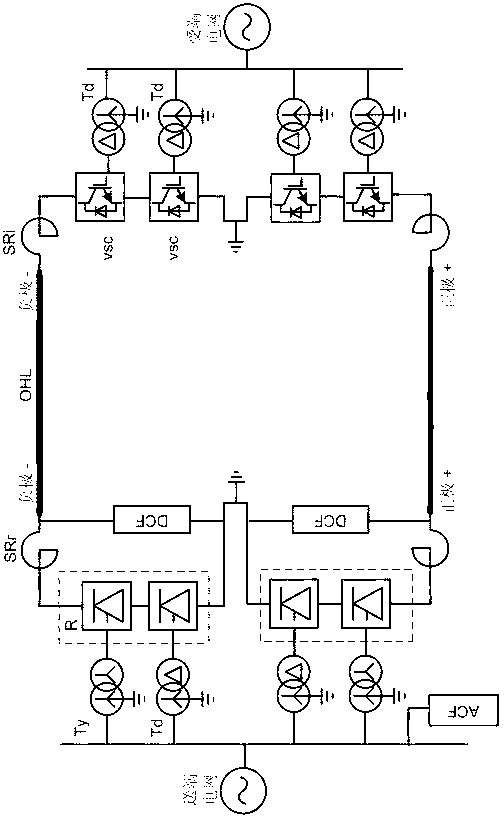

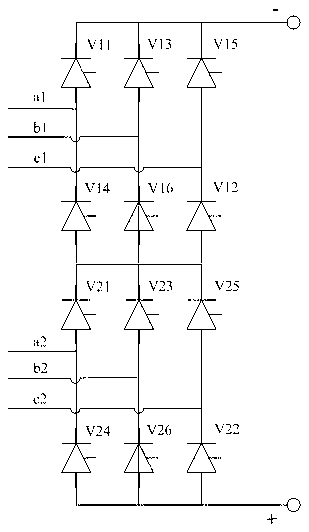

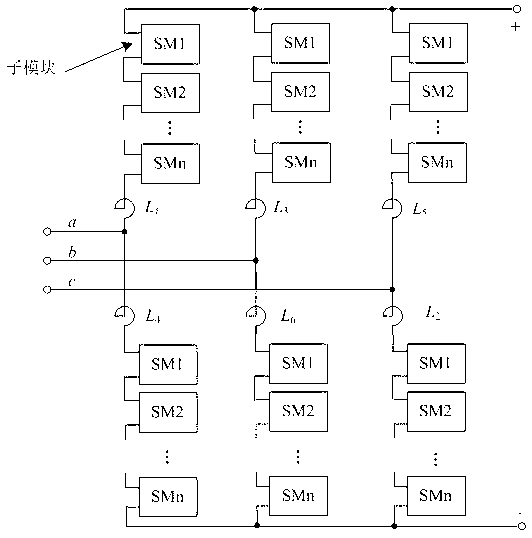

[0023] A compound high-voltage direct current transmission system of the present invention, the compound high-voltage direct current transmission system of the present invention includes at least one rectifier station, one inverter station and overhead power transmission lines, and both the rectifier station and the inverter station include positive and negative poles , where the rectifier station uses a thyristor converter, and the positive and negative poles of the thyristor converter include at least a twelve-pulse thyristor converter; the inverter station uses a voltage source converter with DC fault handling capability, and the voltage source converter The positive pole and the negative pole of the inverter include at least two modular multilevel converters connected in series; The ground electrode or the ground grid in the station are connected, and the rectifier station and the inverter station are connected through overhead power transmission lines.

[0024] Both the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com