Machine vision system

A technology of machine vision inspection and parts program, which is applied in general control systems, control/regulation systems, instruments, etc., and can solve problems such as unfavorable movement of platforms under environmental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

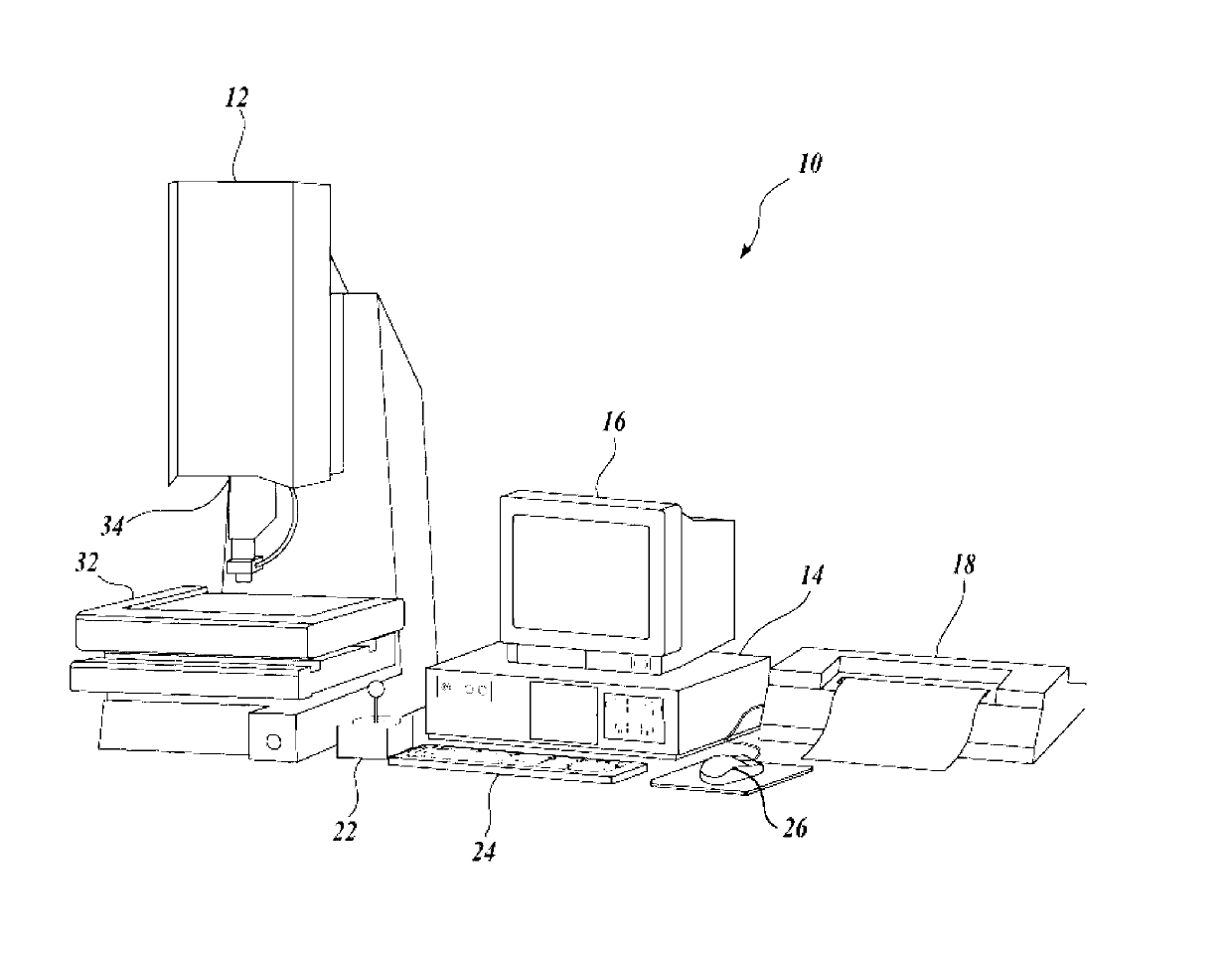

[0042] figure 1 is a block diagram of an exemplary machine vision inspection system 10 that may be used in accordance with the methods described herein. The machine vision inspection system 10 includes a vision measurement machine 12 operably connected to exchange data and control signals with a control computer system 14 . Control computer system 14 is also operably connected to exchange data and control signals with monitor or display 16 , printer 18 , joystick 22 , keyboard 24 and mouse 26 . Monitor or display 16 may display a user interface suitable for controlling and / or programming the operation of machine vision inspection system 10 .

[0043] Vision measurement machine 12 includes a movable workpiece stage 32 and an optical imaging system 34 that may include a zoom lens or interchangeable lenses. Zoom lenses or interchangeable lenses typically provide various magnifications to the image provided by optical imaging system 34 . Machine vision inspection systems 10 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com