Method used for implementing two-stage mixing optimized batch processing scheduling and based on variable time window

A technology of time window and batch processing, which is applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve the problems of low precision, long running time of scheduling algorithm, and multi-entry characteristics increase the difficulty of scheduling, etc., to achieve real-time optimization Scheduling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

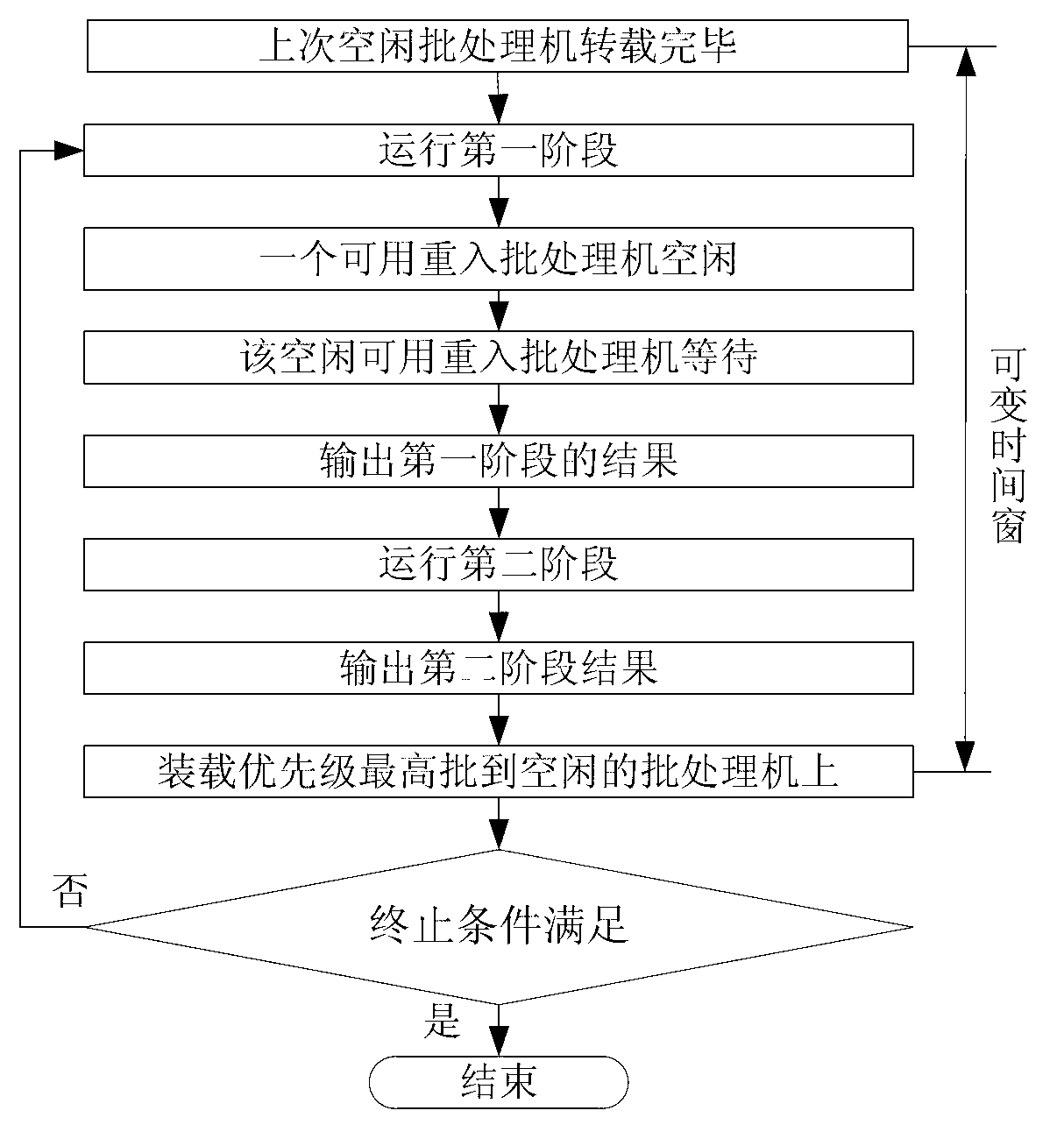

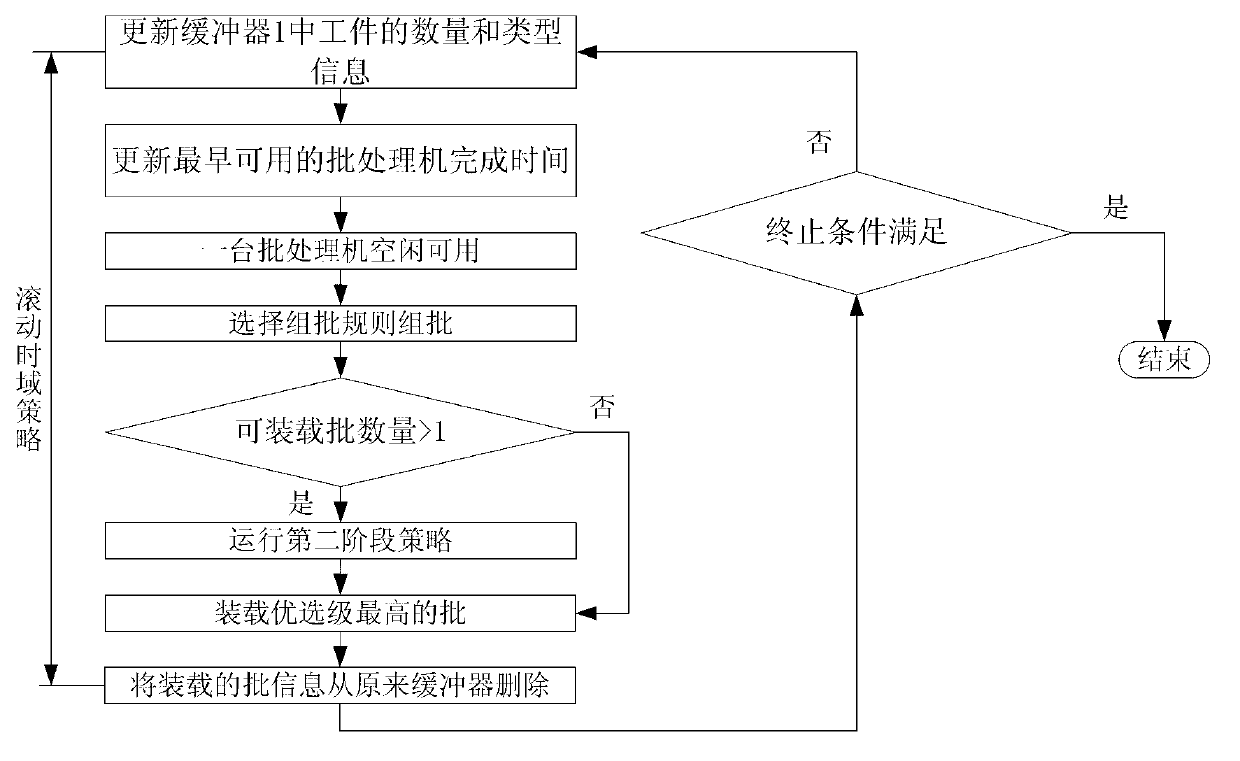

[0034] see figure 1 , a typical virtual model of batch processing with reentrant characteristics, mainly including four device groups: device group one 11, device group two 9, device group three 4 and device group four 6, among which device group one 11 is upstream of device group two 9 Equipment group; equipment group 2 9 is the researched batch processor, which is multi-machine parallel (in the dotted line box in the figure, not marked); equipment group 3 4 and equipment group 4 6 are equipment groups downstream of equipment group 2 9. The product flow direction is to enter from equipment group one 11 and output from equipment group four 6 . Equipment group one 11, equipment group two 9 and equipment group three 4 have buffer one 10, equipment group two 9 and equipment group three 4 have buffer two 3, equipment group two 9 and equipment group 4 have buffer two Buffer Three 7. The workpieces in buffer one 10 come from the re-entry flow of equipment group one 11 and equipmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com