Online automatic detecting and defoaming method for bonding spray glue

An automatic detection and glue spraying technology, which is applied in the direction of material inspection products, foam dispersion/prevention, etc., can solve the problems of barreled glue treatment, air bubbles, uneven mixing, etc., and achieve high defoaming efficiency, easy operation and maintenance, and reliable operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Further illustrate by the following examples.

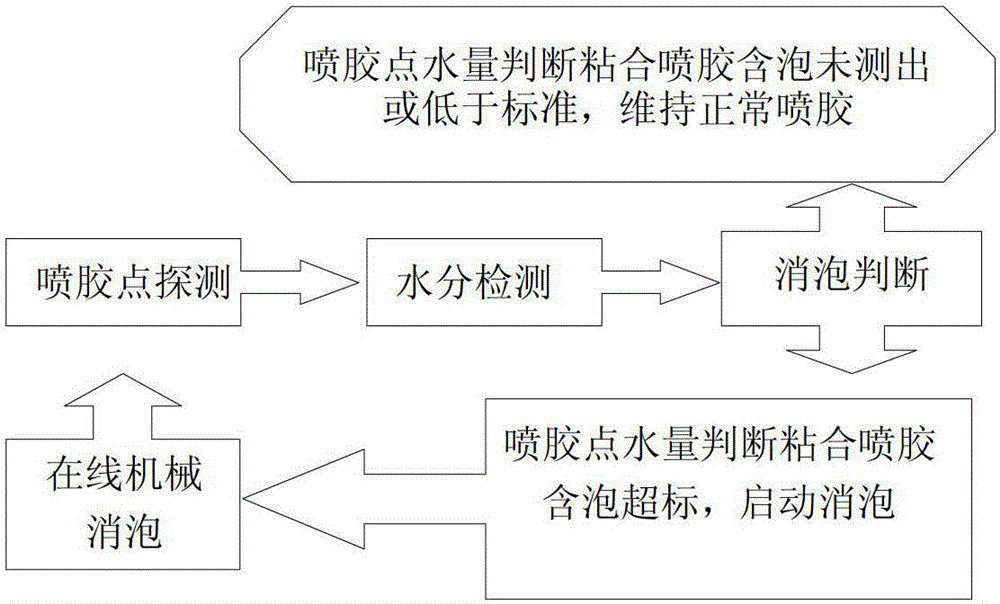

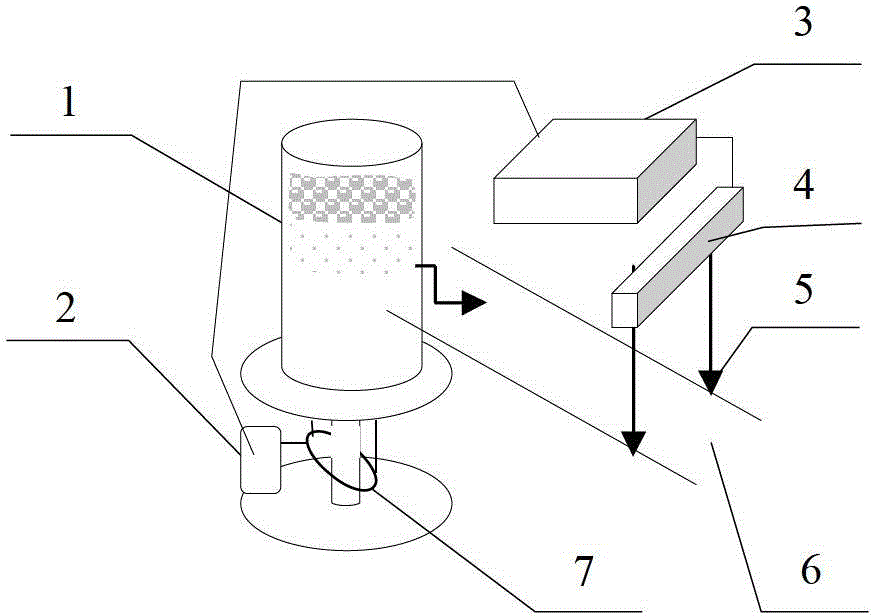

[0020] as attached figure 1 As shown, the glue spraying test is carried out before the glue spraying is updated or the printing operation is on the machine; or online detection is carried out during production; the glue spraying point is detected through the detection head, and the water amount of the glue spraying point is controlled by a moisture detection system. The defoaming judgment is based on the evaluation of the water volume of the glue point. If the water volume of the glue point judges that the foam in the glue spray is not detected or is lower than the standard, no need to defoam; if the water volume of the glue point judges that the foam in the glue spray exceeds the standard, start Defoaming, and then start the online physical defoaming until the glue point detection and defoaming judge that the foam is not detected or is lower than the standard, so there is no need to defoam.

[0021] In the foregoing, as...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com