Pitch-varying design method of inducer with long and short blades

A technology of long and short blades and design methods, applied in mechanical equipment, non-variable pumps, components of pumping devices for elastic fluids, etc., can solve the problem of reducing the efficiency of the inducer and anti-cavitation performance, shedding and boundary Layer separation and other issues, to improve efficiency and anti-cavitation performance, to avoid the effect of boundary layer separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

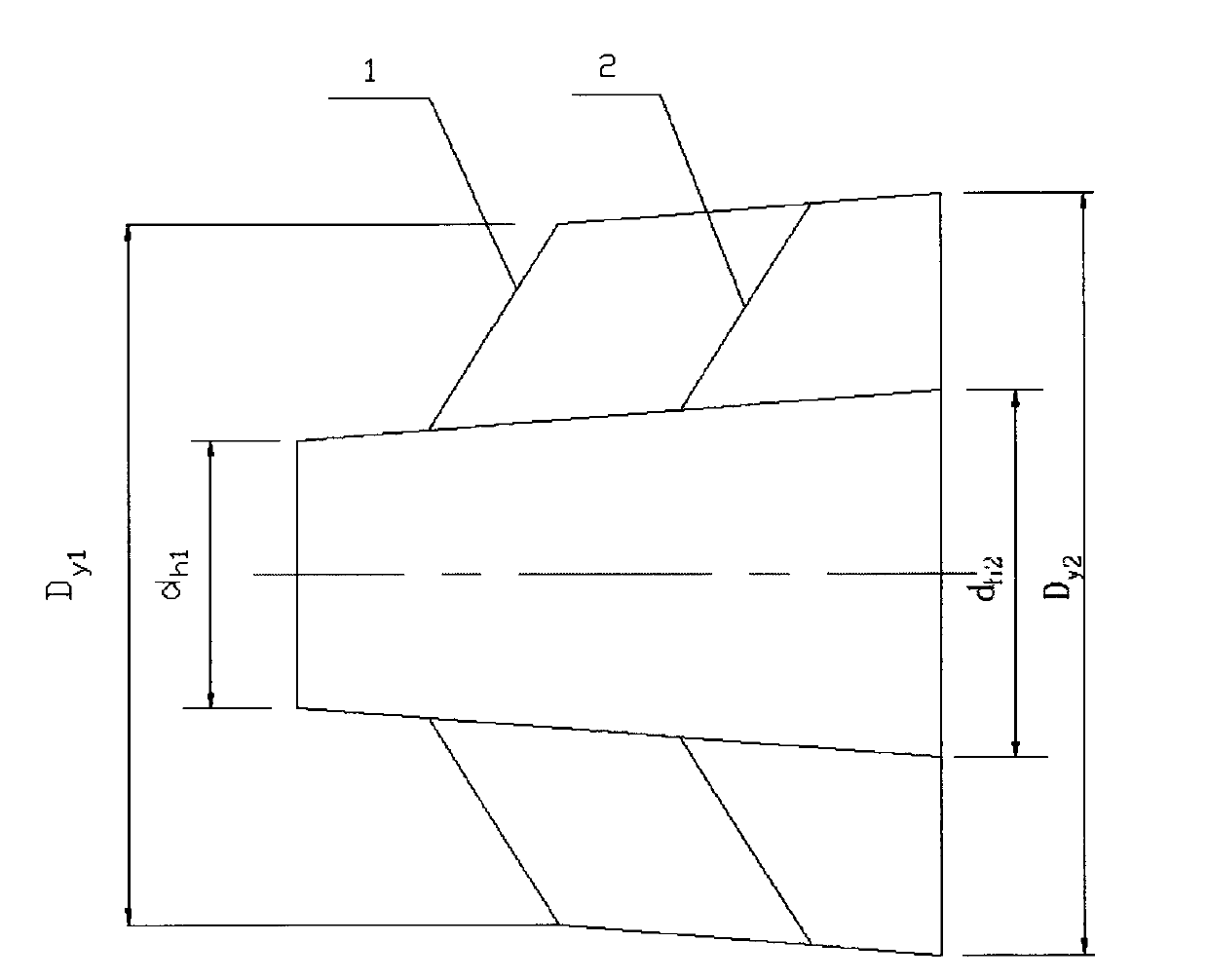

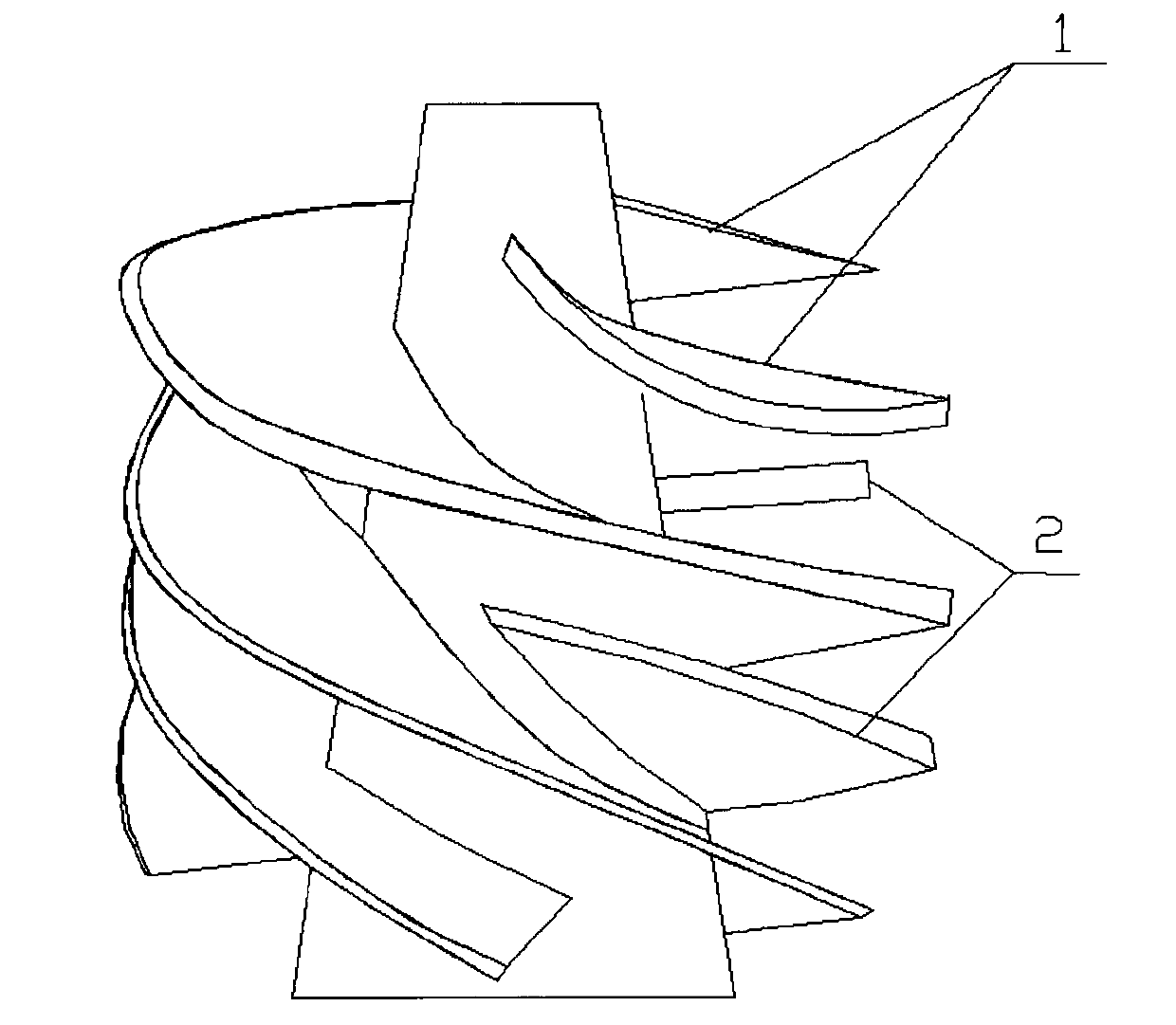

[0049] figure 1 with figure 2 Together determine the shape of this embodiment inducer. It has a tapered hub like most tapered inducers. The blades of the inducer are divided into two types: long blades (1) and short blades (2). The long and short blades are arranged alternately. There are two long and short blades on the inducer. The short blades extend from the middle of the inducer to the exit. Its main purpose is to avoid shedding and boundary layer separation near the outlet of the inducer blades, improve the outlet flow field, and improve the efficiency and anti-cavitation performance of the inducer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com