Roller heating system for electric heat drying and ironing

A heating system and drum technology, applied in applications, ironing machines, household appliances, etc., can solve the problems of wasting heat energy, low work efficiency, waste of resources, etc., and achieve high heat transfer efficiency, convenient adjustment and operation, and advanced and reasonable structural design Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

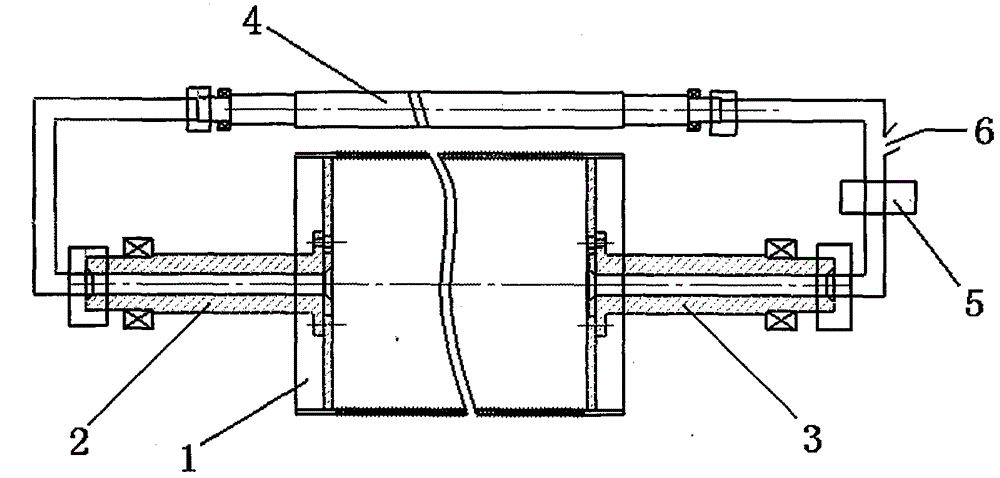

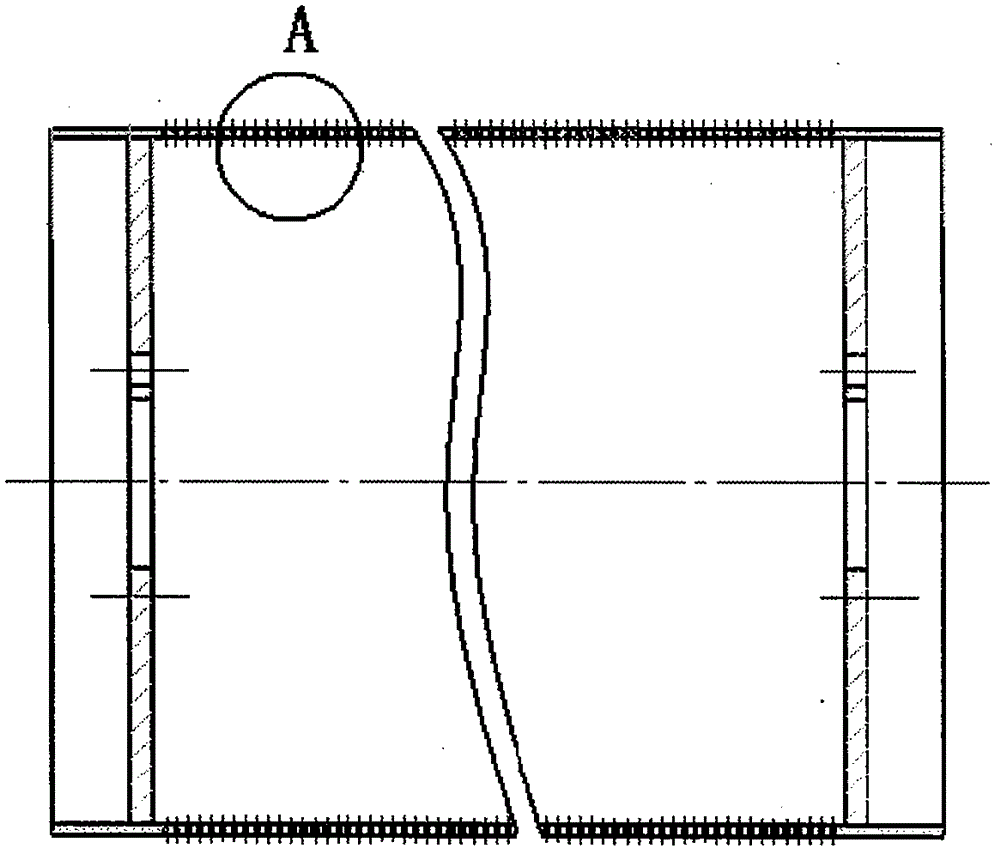

[0016] Please refer to the accompanying drawings to illustrate its implementation process:

[0017] A drum heating system for electric drying and ironing, comprising a drum 1, an electric heating tube is arranged inside the drum 1, air holes are uniformly arranged on the wall of the drum 1 along the circumferential direction and the axial direction, and the two ends of the drum 1 are respectively provided with Drive shaft one 2 and drive shaft two 3 communicated with the interior, the drive shaft one 2 is connected to one end of the driven roller 4 through the rotary joint and the air pressure pipe, and the other end of the driven roller 4 is connected to the driven roller 4 through the rotary joint and the air pressure pipe. The fan 5 is connected, and the fan 5 is connected with the drive shaft 2 3 through a wind pressure pipe and a rotary joint. The vertical air hole can be proportioned according to the diameter of the drum, and its diameter is 0.5 to 10 mm. The blower fan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com