Method for preparing flash glazed wall tile

A flash glaze and ceramic tile technology, applied in the field of building materials, can solve the problems of increased production costs, sensitivity, and large energy consumption, and achieve the effects of reducing pollution, reducing costs, and reducing harmful components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

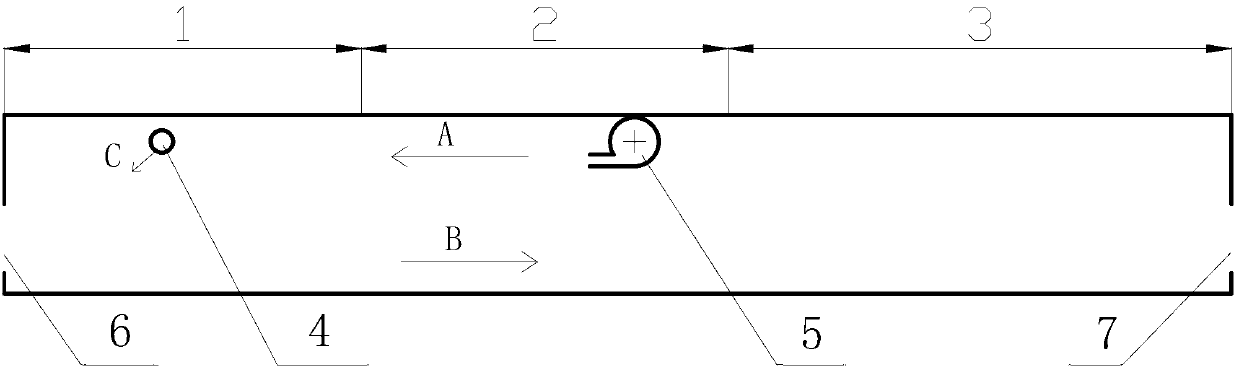

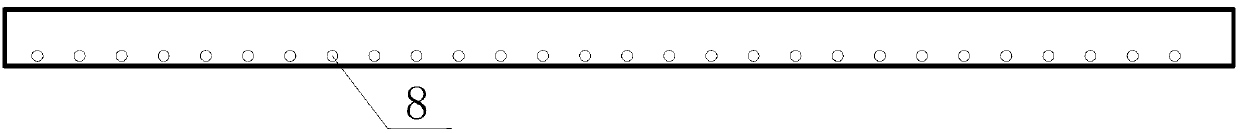

[0100] A roller kiln consists of a kiln chamber, combustion equipment (not shown in the drawings), ventilation equipment (not shown in the drawings), and conveying equipment (not shown in the drawings). The brick inlet 6 to the brick outlet 7 includes a heating section and a cooling section 3 in turn, and the heating section includes a preheating section 1 and a firing section 2 in turn, and the farther the heating section is from the brick inlet, the higher the temperature. High; a dehumidifying fan 5 is set in the firing section to discharge the kiln waste gas out of the kiln chamber; a straight pipe is installed above the tile transportation surface of the preheating section 1 as a cold air pipe 4, and the cold air pipe 4 is Set blowing holes 8, the blowing holes are evenly arranged on the cold air pipe, and the air outlet direction (C direction) of the blowing holes is obliquely downward to blow air, and is opposite to the conveying direction of the tiles (the air outlet di...

Embodiment 2

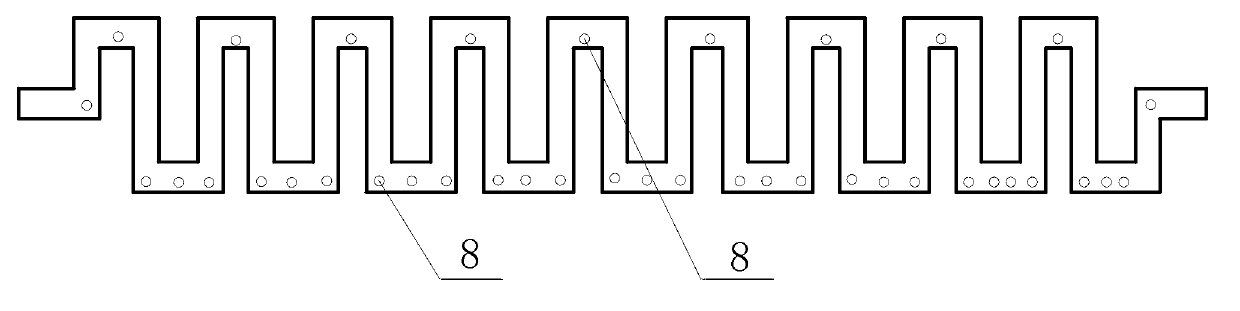

[0105] A roller kiln is composed of a kiln chamber, combustion equipment, ventilation equipment, and conveying equipment. The kiln chamber includes a heating section and a cooling section in turn from the brick inlet to the brick outlet. The heating section includes a preheating section in turn. Section and firing section, the farther the heating section is from the brick inlet, the higher the temperature; a dehumidifier is installed in the firing section to discharge the kiln waste gas from the kiln chamber; the ceramic tile transportation surface in the preheating section An S-shaped pipe is installed on the top of the cold air pipe as a cold air pipe, and blowing holes are arranged on the cold air pipe, and the blowing holes are evenly arranged on the cold air pipe. The direction is opposite (the air outlet direction of the blowing hole is at an angle of 60° to the horizontal), the aperture of the blowing hole is 3mm; and the cold air pipe can vibrate;

[0106] The cold air...

Embodiment 3

[0109] A roller kiln is composed of a kiln chamber, combustion equipment, ventilation equipment, and conveying equipment. The kiln chamber includes a heating section and a cooling section in turn from the brick inlet to the brick outlet. The heating section includes a preheating section in turn. Section and firing section, the farther the heating section is from the brick inlet, the higher the temperature; a dehumidifier is installed in the firing section to discharge the kiln waste gas from the kiln chamber; the ceramic tile transportation surface in the preheating section There are 3 straight pipes installed above as cold air pipes. Blowing holes are arranged on the cold air pipes. The blowing holes are evenly arranged on the cold air pipes. The same (the air outlet direction of the blowing hole is at an angle of 45° to the horizontal), the aperture of the blowing hole is 7mm; and the cold air pipe can vibrate;

[0110] The cold air pipe is installed at 480-550°C in the preh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com