Biochemical strengthening treater

A processor and biochemical technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of difficulty in improving water quality, easy clogging of microporous aerators, and treatment costs Advanced problems, to achieve the effect of improving oxygenation efficiency and mass transfer rate, accelerating organic matter degradation rate and microbial growth rate, and high oxygenation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

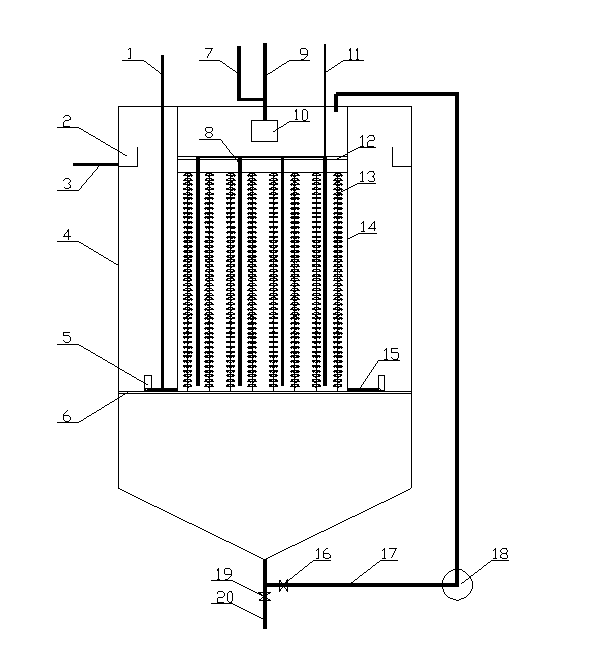

[0022] see figure 1 , an embodiment of a biochemical enhanced processor of the present invention, the shell 4 of the biochemical enhanced processor is made of a steel plate with a certain thickness (such as: carbon steel plus glass fiber reinforced plastic or stainless steel) to make a circular cylinder, the upper part is cylindrical, and the lower part It is conical and supported by a base. Ozone generating equipment and iron salt dosing equipment are arranged outside the housing 4 of the biochemical enhancement processor.

[0023] A support frame 6 is set in the lower part of the housing 4 , and a central cylinder 14 is arranged in the middle of the housing 4 . The central cylinder 14 is equipped with biological fillers 13, the biological fillers 13 are sheet-shaped composite fillers, each sheet-shaped composite filler is formed into a string of biologic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com