Biological rotary disk device having filtration cavity

A biological turntable and filtration chamber technology, applied in sustainable biological treatment, ultrafiltration, semi-permeable membrane separation, etc., can solve the problems of many system processes, high cost, low efficiency, etc., and achieve high oxygenation efficiency and stable solid-liquid The effect of the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

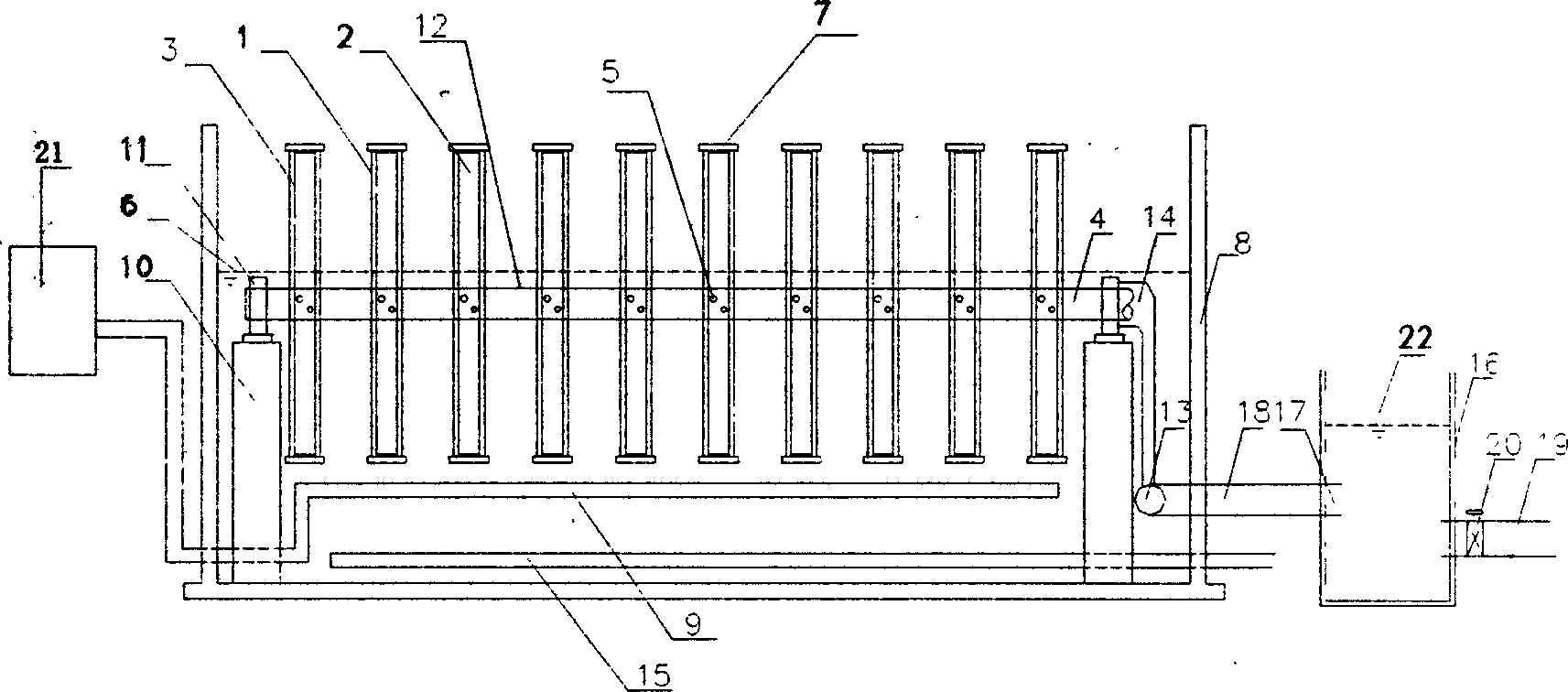

[0016] Embodiment 1: Apply the present invention to treat urban sewage.

[0017] In this embodiment, a biodegradable plastic net with a pore size of 0.5 mm is used as the filter membrane material, such as figure 1 The rotating biofilm device shown in work, 1 is the filter membrane, 2 is the cavity composed of two filter membranes, 3 is the cavity support, 4 is the main shaft of the rotary biofilm device, one end is closed, the other end is open, 5 The small hole for passing water that the main shaft opens in the cavity, and 7 is an air cup installed on the filter cavity. 6 is the water level of the reaction tank, 8 is the reaction tank, 9 is the aeration pipe, arranged at the bottom of the reaction tank, 10 is the base, the base is in the reaction tank, the base is equipped with a bearing seat and a bearing 11, and the main shaft 5 of the rotating biofilm device 12 The two ends of the two ends are placed in the bearing, and the bearing seat at the open end of the main shaft i...

Embodiment 2

[0018] Embodiment 2: Apply the present invention to treat urban sewage.

[0019] In this embodiment, the same rotating biofilm device as in Embodiment 1 is used, wherein the filter membrane is selected as a nylon mesh with a mesh aperture of 0.1 mm, the reaction tank is an oxidation ditch, and the operating parameters of the oxidation ditch are: the concentration of the mixed liquid suspended sludge is 8000-9000mg / l, the hydraulic retention time is 5 hours, the sludge retention time is 25 days, the average dissolved oxygen concentration is controlled at 1-2mg / l, the influent water quality is at COD200-400mg / l, and the suspended solids are at 100- 200mg / l, completely submerge the rotating biofilm device under water. Implementation effect: the effluent water quality is 30-50mg / lCOD, and the concentration of suspended solids is controlled below 3mg / l.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com