Belt separating unit

A separation device and belt technology, used in transportation and packaging, conveyors, conveyor objects, etc., can solve problems such as low efficiency, scratches, time-consuming and labor-intensive

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

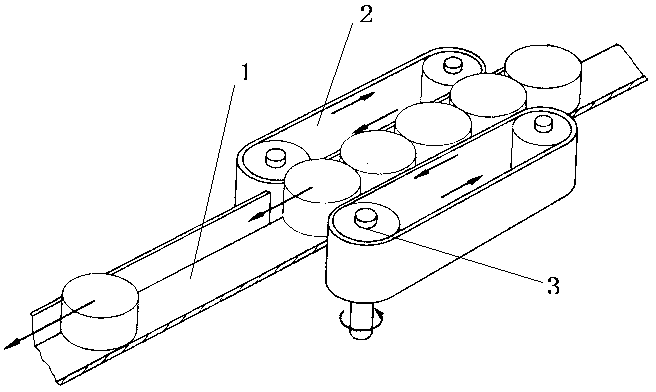

[0010] Such as figure 1 Shown: The belt separation device includes a workpiece storage part and a separation part. The workpiece storage part is a chute 1 arranged horizontally; the separation part includes two endless belts 2 which are symmetrical to the chute 1 and arranged close to the chute 1. The belt 2 consists of Belt pulley 3 drives, and the motion direction of two belts 2 is the same.

[0011] In this embodiment, the workpiece storage part is a horizontally arranged chute 1, and the workpiece flows in from one end of the chute 1, and the workpiece is pushed to the other end of the chute 1 by two moving belts 2 on the side of the chute 1, and enters the lower end of the chute 1. One-step machining equipment; at the same time, the belt 2 is driven by the pulley 3, and the two belts 2 move in the same direction, so that the rotation speed of the pulley 3 can be adjusted to facilitate the control of the flow rate of the workpiece. The above structure not only facilitates...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com