Auxiliary brake device applied to non-drive axle

A non-drive axle, auxiliary braking technology, applied in the direction of brakes, brake components, brake types, etc., can solve the problems of heavy load, overheating of brake drums and brake pads, affecting driving safety, etc., to reduce The effect of maintenance cost, reduction of maintenance frequency, and traffic accident avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

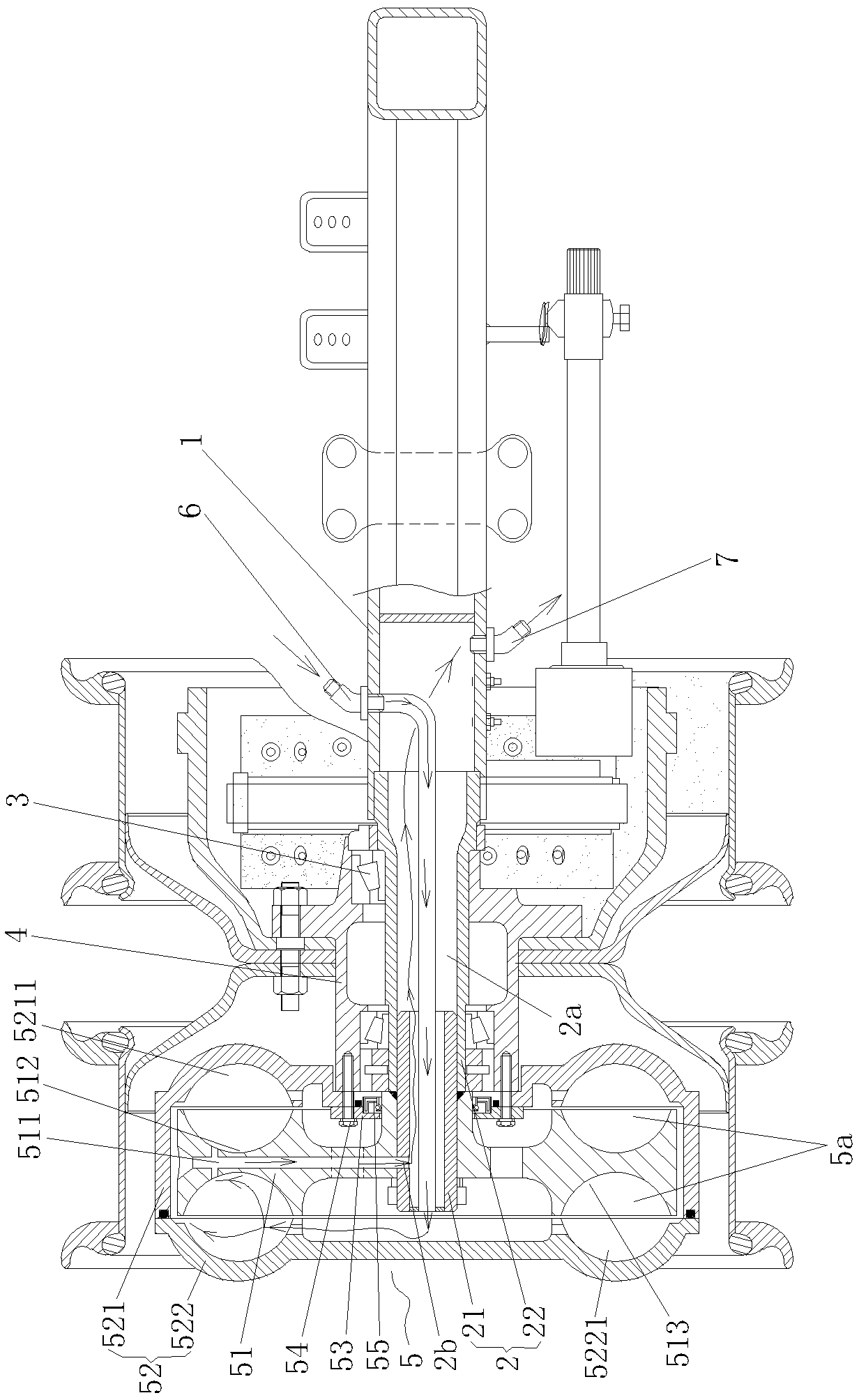

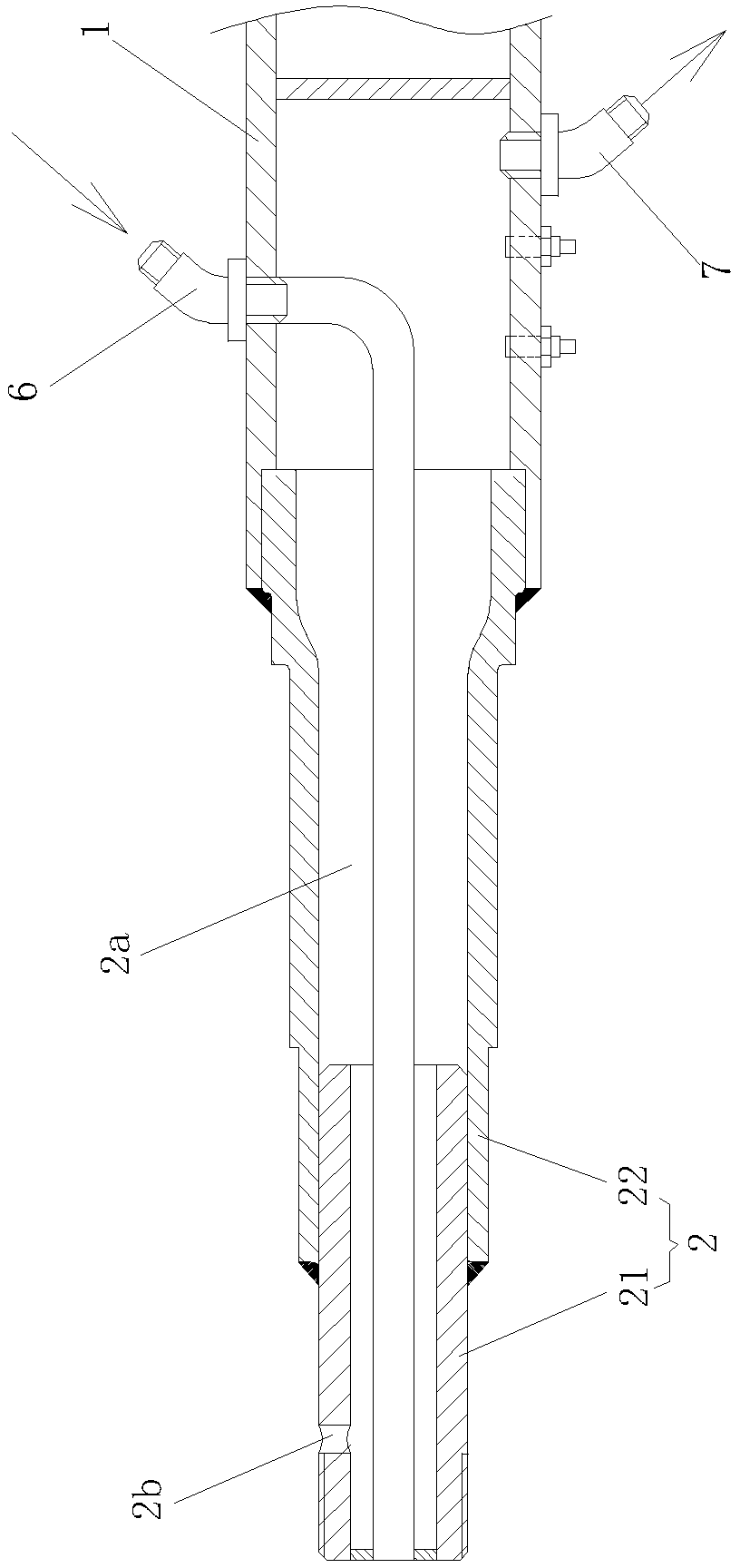

[0028] Example one figure 1 , figure 2 , image 3 As shown, an auxiliary braking device applied to a non-driving axle includes an axle housing 1 of the non-driving axle. Both ends of the axle housing 1 are fixed with axle heads 2, and the outer surface of each axle head 2 passes through a bearing 3 is connected to the hub 4, a hydraulic retarder 5 is installed between the end of the hub 4 and the shaft head 2, and each shaft head 2 is provided with an axial through hole 2a, and the axial through hole 2a constitutes A part of the oil passage of the hydraulic retarder 5, and the oil inlet pipe 6 and the oil return pipe 7 are installed on the axle housing 1;

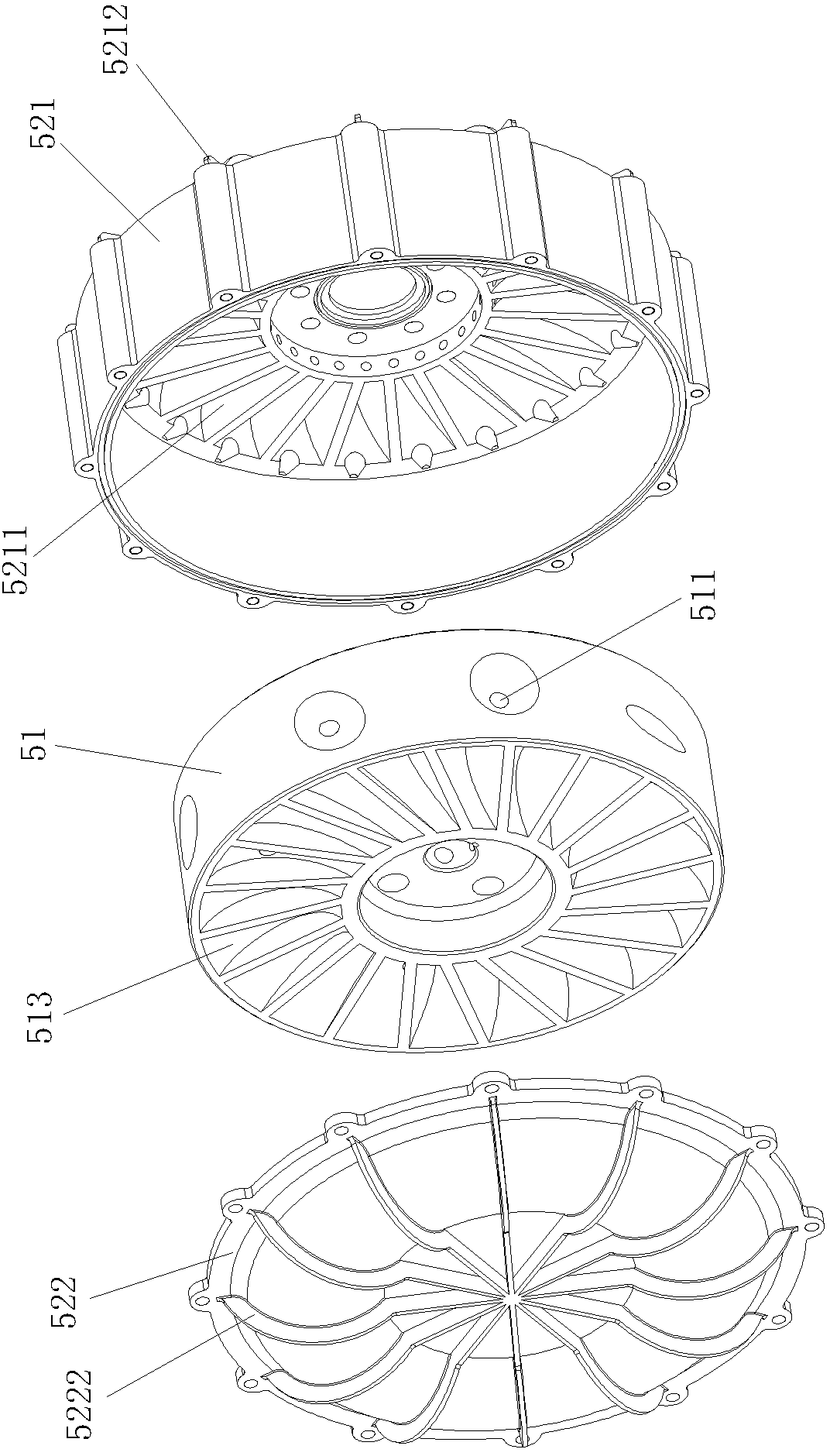

[0029] The hydraulic retarder 5 includes a stator impeller 51 fixed on the outer surface of the end of the shaft head 2, and a rotor impeller 52 that is wrapped around the stator impeller 51 and fixed to the hub 4. The inner surface of the rotor impeller 52 A hydraulic oil working chamber 5a is formed between the outer surfac...

Embodiment 2

[0045] Embodiment two Figure 5 , Image 6 , Figure 7 As shown, the difference from the first embodiment is that the end face of the stator impeller 51 and the front rotor impeller 522 is not provided with multiple damping slots, and the end face of the front rotor impeller 522 and the stator impeller 51 is also not provided with multiple phases. Corresponding damping groove;

[0046] The outer surface of each shaft head 2 close to the hydraulic oil working chamber 5a is radially provided with a radial oil inlet 2c communicating with the axial through hole 2a, and the stator impeller 51 is provided with an oil passage 513 and the radial The oil inlet 2c is matched, the oil return pipe 7 passes through the axial through hole 2a of the shaft head 2 to communicate with the hydraulic oil working chamber 5a, and is close to the axial through hole 2a of the shaft head 2 of the hydraulic oil working chamber 5a. A seal is formed between the inner surface of the axle housing 1 and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com