Three-degree-of-freedom plane parallel mechanism with novel redundant drive branched-chain

A technology for driving branch chains and degrees of freedom, applied in manipulators, manufacturing tools, program-controlled manipulators, etc., can solve the problems of difficult to achieve optimal control, increase control complexity, reduce loading accuracy, etc., achieve compact structure, increase rigidity, The effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

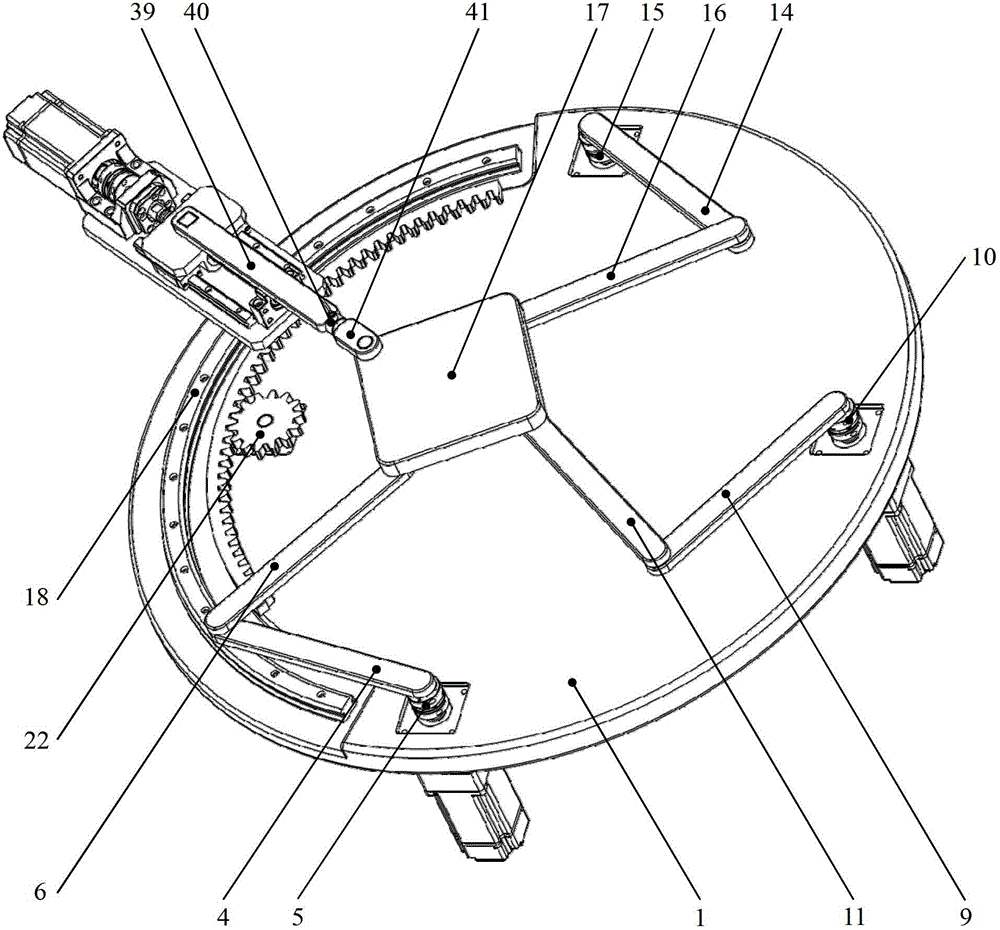

[0026] The working process of the three-degree-of-freedom planar parallel mechanism with novel redundant drive branch chain described in the present invention is described in detail as follows:

[0027] Such as figure 1 As shown, what the parallel mechanism needs to control is the position and rotation angle of the moving platform 17 . After giving its position and rotation angle, according to figure 1 In the assembly mode shown, the rotation angles of the first connecting rod 4, the third connecting rod 9 and the fifth connecting rod 14 can be respectively obtained through the inverse solution of the position of the mechanism, and the corresponding servo motors are used to control the rotation angles to obtain the required motion. The pose of platform 17. The redundant drive branch chain is to further improve the rigidity of the mechanism and the dynamic operation accuracy of the moving platform; through the analysis of the dynamic characteristics of the mechanism, the opti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com