Gas-liquid distribution plate capable of reducing horizontal susceptibility

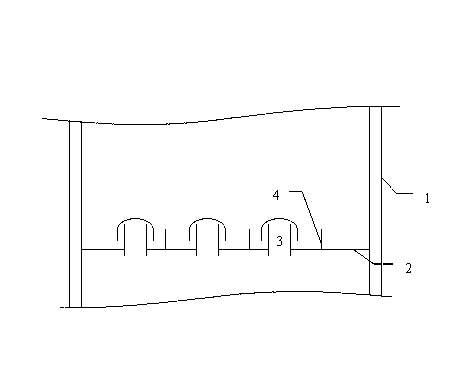

A gas-liquid distribution and gas-liquid distributor technology, which is applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of high level sensitivity, no consideration of the levelness of the distribution plate, etc. Simple structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

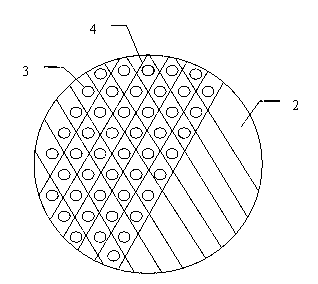

[0028] Such as figure 2 As shown, suction-type gas-liquid distributors 3 are arranged on the gas-liquid distribution tray tray 2 , and each gas-liquid distributor 3 is surrounded by a diamond-shaped liquid phase cofferdam 4 . The height of the liquid phase cofferdam is 1.0 times the height from the bottom edge of the bubble cap to the gas-liquid distribution plate 2 . When the tray 2 of the gas-liquid distribution tray is horizontally deflected, a small area of relatively independent liquid surface will be maintained between the liquid phase cofferdams 4 to ensure that the gas-liquid distributor 3 in the liquid phase cofferdams 4 can continue to function.

Embodiment 2

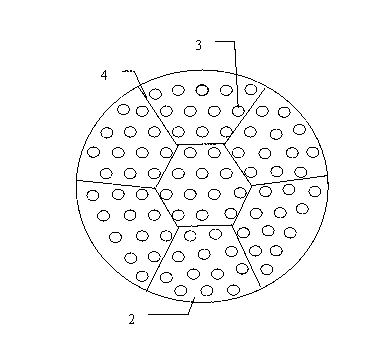

[0030] Such as image 3 As shown, suction type gas-liquid distributors 3 are arranged on the gas-liquid distribution tray 2 , and a plurality of gas-liquid distributors 3 are surrounded by a liquid phase cofferdam 4 . The liquid phase cofferdam in the middle is hexagonal, and the other liquid phase cofferdams are fan-shaped. The height of the liquid phase cofferdam is 1.2 times the height from the bottom edge of the bubble cap to the gas-liquid distribution plate 2 . When the gas-liquid distribution plate tray 2 is horizontally deflected, a small area of relatively independent liquid surface will be maintained between the liquid phase cofferdams 4 to ensure that the multiple gas-liquid distributors 3 in the liquid phase cofferdams 4 have the corresponding Adapt to the liquid level, better play a role.

Embodiment 3

[0032] Such as Figure 4 As shown, suction type gas-liquid distributors 3 are arranged on the gas-liquid distribution tray 2 , and a plurality of gas-liquid distributors 3 are surrounded by a liquid phase cofferdam 4 . The liquid phase cofferdam in the middle is circular, and the circular liquid phase cofferdam is surrounded by fan-shaped liquid phase cofferdams. The height of the liquid phase cofferdam is 1.5 times the height from the bottom edge of the bubble cap to the gas-liquid distribution plate 2 . When the gas-liquid distribution plate tray 2 is horizontally deflected, a small area of relatively independent liquid surface will be maintained between the liquid phase cofferdams 4 to ensure that the multiple gas-liquid distributors 3 in the liquid phase cofferdams 4 have the corresponding Adapt to the liquid level, better play a role.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com