Multi-type material continuously feeding method for

A kind of material type and silo technology, applied in the field of continuous feeding of multiple types of materials, can solve the problems of not being able to accurately grasp the moving position of materials, consuming feeding time, reducing feeding efficiency, etc., so as to avoid waiting time for materials to empty, Achieve online switching and improve feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

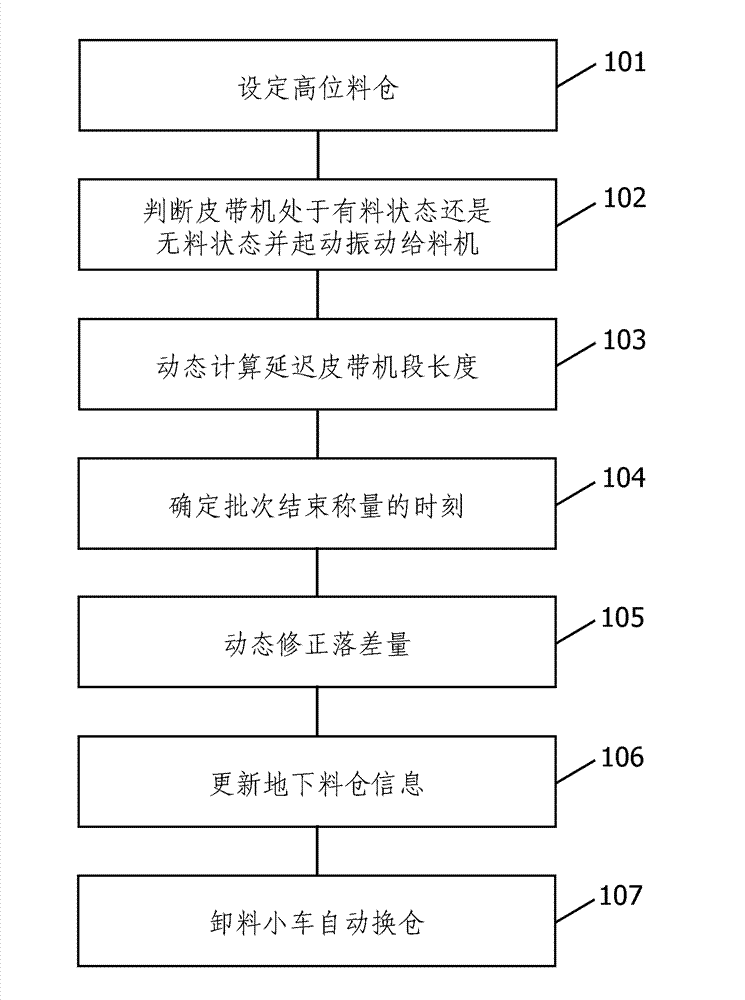

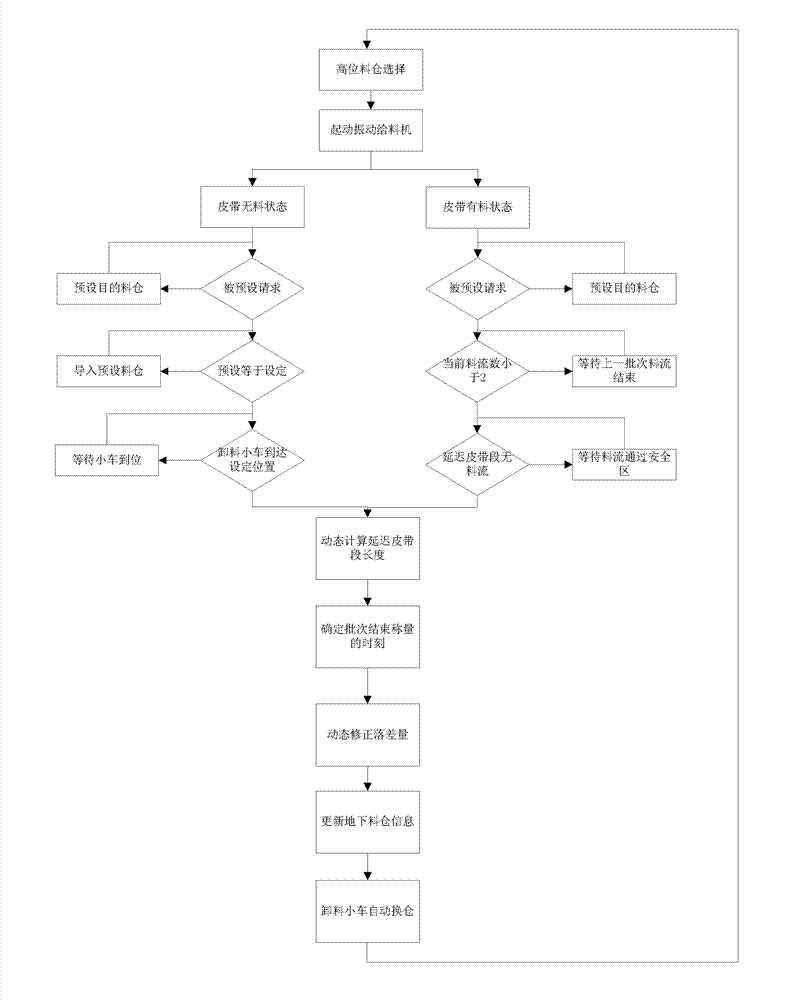

[0028] refer to figure 1 As shown, the present invention discloses a kind of multi-material kind continuous feeding method, and this method comprises the steps:

[0029] 101. Setting the high-level silo includes setting the current silo and setting the preset silo, where the current silo is the target high-level silo for the current batch of materials, and the preset silo is the target for the next batch of materials High bunker. In one embodiment, when the high-level bin is set in step 101, there is no material on all the belt conveyors.

[0030] 102. Determine whether the belt conveyor is in the state of material or no material and start the vibrating feeder. In one embodiment, the belt conveyor is in a material-free state and starting the vibrating feeder includes the following steps: 1) setting the underground silo as a preset request; 2) setting the preset silo as the current silo ; 3) Move the unloading trolley to the current silo. The belt conveyor is in a material-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com