Deflection-resisting rail spacing device

A fixed-distance and deflection technology, which is applied in the field of rail transit, can solve the problems of anti-rail wear performance, weak tensile and bending resistance, and inability to suppress rail wear and corrugation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

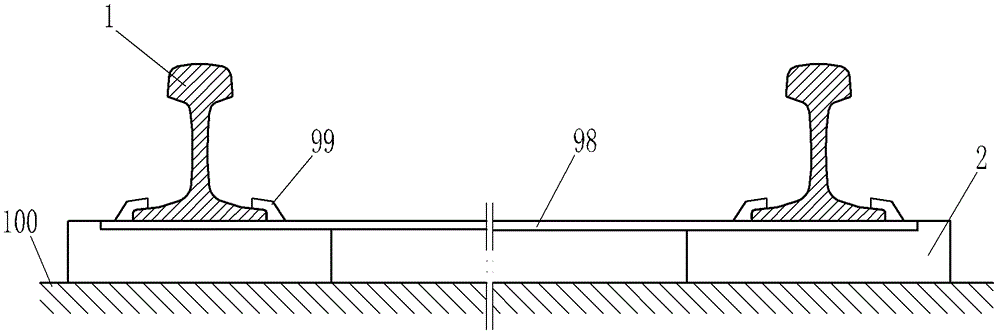

[0071] Such as figure 1 As shown, taking the short sleeper ballastless track bed as an example, the short sleeper 2 is fixed on the track bed 100, and the steel rail 1 is erected above the short sleeper 2. The existing fixed-distance connecting rod includes a connecting rod 98 arranged between two parallel steel rails 1, and bayonets 99 are arranged at both ends of the connecting rod 98, and the bayonets 99 are respectively locked and fixed at the rail bottoms of the two steel rails 1. The connecting rod 98 in the existing fixed-distance connecting rod is basically designed for tensile strength, and the bending moment is less considered. Therefore, the existing fixed-distance connecting rod is strong in tension and weak in bending. Therefore, this fixed-distance connecting rod can ensure that the rail The gauge of the bottom, but it cannot limit the vibration displacement of the rail head due to the bending moment. Because the bayonet of this distance bracket is locked at the...

Embodiment 2

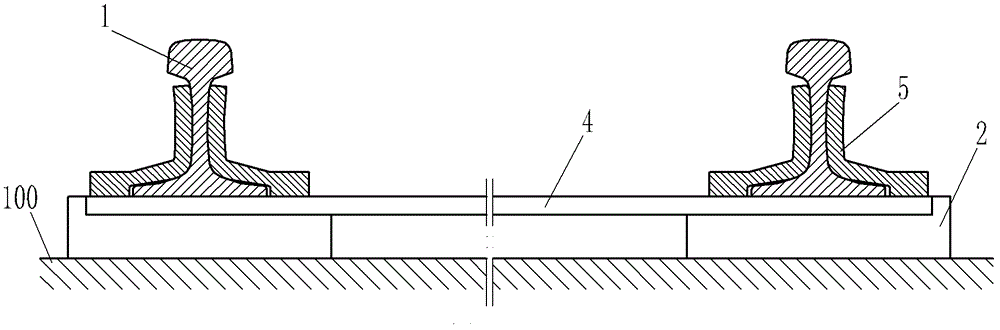

[0080] Such as Figure 5 The difference between the track anti-sway distance fixing device of the present invention and the first embodiment is that the anti-bending link beam 4 is made of glass fiber reinforced plastics, and the anti-sway splint 5 is fixed on the anti-bending link beam 4 by fasteners 8 .

[0081] Since the detachable structure is adopted between the anti-sway splint 5 and the anti-bending beam 4, assembly, maintenance and replacement are more convenient, and the installation of the track anti-sway distance fixing device of the present invention can be completed without disassembling the rail Or replacement, it is suitable for the transformation of existing lines or the laying of new lines, especially suitable for use on seamless steel rails that are widely used at present.

Embodiment 3

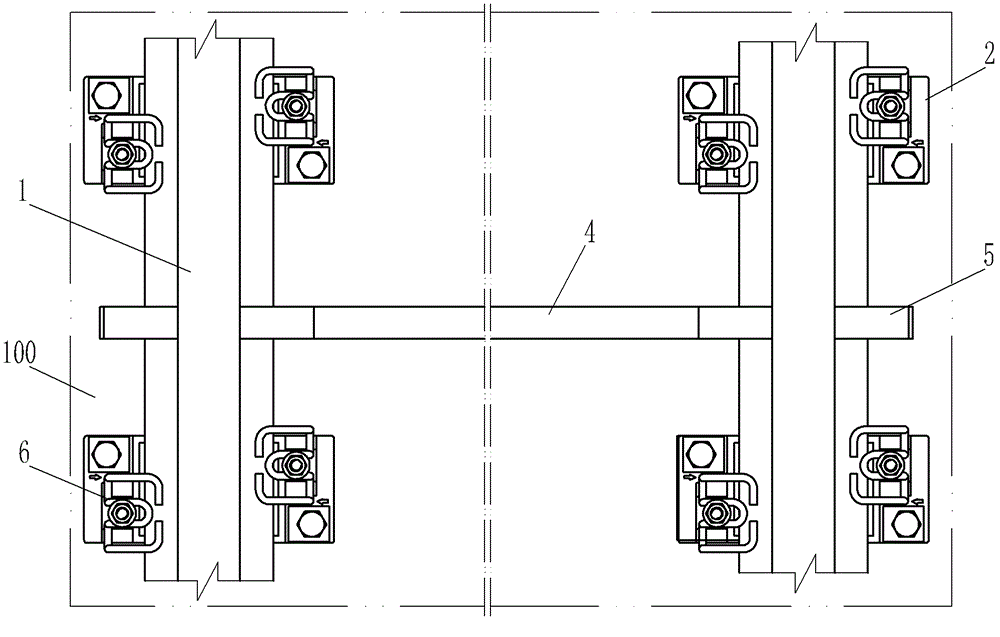

[0083] Such as Figure 6 The difference between the track anti-yaw and distance fixing device of the present invention shown in Embodiment 2 is that the track anti-yaw and distance fixing device of the present invention can also be used for short sleepers with ballast beds, and ballast 9 is normally laid on the ballast bed 100. Can. Additionally, using Figure 6 The shown anti-swing splint 5 has a higher clamping load-bearing point for the rail waist and a stronger ability to withstand the force distance of the rail head, so the performance of anti-sway deflection of the rail is better. In addition, in order to reduce assembly links and improve installation efficiency, two anti-sway splints 5 in the same direction in the clamping assembly are welded and fixed on the anti-bending beam 4, and the other two anti-sway splints 5 in the same direction are fixed by fasteners 8 On the anti-bending beam 4. The anti-bending link beam 4 is made of square steel rods.

[0084] When ass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com