Preparation method of glutinous essence

A technology of essence and waxy flavor, which is applied in the field of preparing natural heat-reactive waxy flavor, can solve the problems of short processing time and achieve the effects of good product quality, mild enzyme action conditions, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

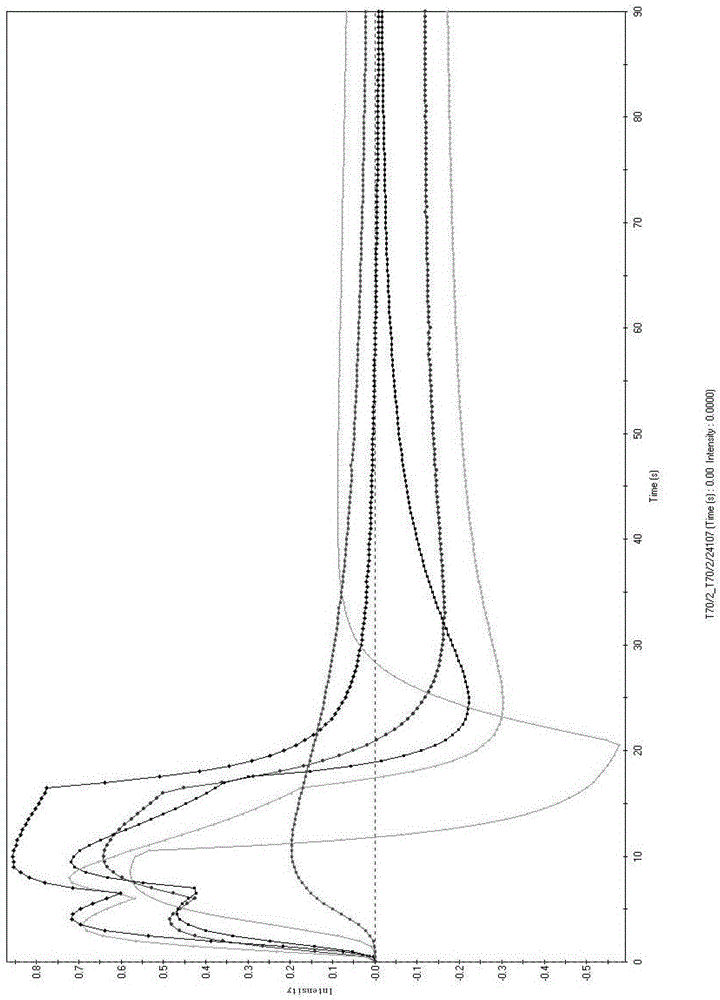

Image

Examples

Embodiment 1

[0040] (1) Preparation of raw materials: cleanly select dried orange peel produced in Zhejiang Province, remove the impurities, crush it, and pass through a 60-100 mesh sieve to obtain dry orange peel powder for use;

[0041] (2) Reagents: 95% ethanol, glycerol, Coomassie brilliant blue reagent, DNS reagent; glucose, bovine serum albumin.

[0042] (3) Instruments: HMB-701C pulverizer, H1650 high-speed centrifuge, DHG-9240A electric blast drying oven, BC / BD-199DSA Haier horizontal double-door refrigerator-freezer conversion cabinet, DK-8D electric constant temperature water tank (temperature fluctuation : ±0.5℃), RE-52A rotary evaporator, AL-104 electronic balance (division value: 0.0001g), T6 new century UV-visible spectrophotometer, HH-2 digital display constant temperature water bath, LXJ-Ⅱ centrifugal sedimentation machines, vortex shakers, microwave ovens, etc.

[0043] (4) Determination of amino acids by Coomassie brilliant blue method

[0044] Coomassie Brilliant Blue ...

Embodiment 2

[0079] (1) Preparation of raw materials: cleanly select dried orange peel produced in Zhejiang Province, remove the impurities, crush it, and pass through a 60-100 mesh sieve to obtain dry orange peel powder for use;

[0080] (2) Treatment of raw materials: Take 100g of dried orange peel powder, add deionized water 40 times the mass of dried orange peel powder (4000g), add 0.04% pectinase (enzyme activity is 30000u / g) and 0.2% cellulase (Enzyme activity is 40000u / g), enzymolysis at 45°C and pH 5.0 for 180min; then increase the extraction temperature to 95°C for 60min, centrifuge and filter to obtain filtrate and filter cake, take the filtrate and concentrate to the water content 89wt%, to obtain a concentrated solution of 1.76L.

[0081] (3) Maillard reaction: add 0.29kg (1 / 6 kg / L) of L-aspartic acid and 1.76kg (1 / 1 kg / L) of glycerol to the concentrated solution, control the water content at 44%, and Stir in a stirrer for 120min, then use 0.2mol / L NaHCO 3 Adjust the pH of th...

Embodiment 3

[0084] (1) Preparation of raw materials: cleanly select dried orange peel produced in Zhejiang Province, remove the impurities, crush it, and pass through a 60-100 mesh sieve to obtain dry orange peel powder for use;

[0085] (2) Treatment of raw materials: Take 20g of dried orange peel powder, add deionized water with a mass 100 times (2000g) of dried orange peel powder, add 0.01% pectinase (enzyme activity: 30000u / g) and 0.05% cellulase (Enzyme activity is 40000u / g), enzymolysis at 50°C and pH 4.0 for 90min; then increase the extraction temperature to 85°C and extract for 150min, centrifuge and filter to obtain filtrate and filter cake, take the filtrate and concentrate to the water content 95wt%, to obtain a concentrated solution of 0.92L.

[0086] (3) Maillard reaction: add 0.12kg (1 / 8 kg / L) of L-aspartic acid and 1.84kg (2 / 1 kg / L) of glycerin to the concentrated solution, control the water content at 32%, and Stir in a stirrer for 120min, then use 0.2mol / L NaHCO 3 Adjus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com