Process for realizing natural gas preparation with coke oven gas by using anaerobic microbes

An anaerobic microorganism, coke oven gas technology, applied in sustainable manufacturing/processing, gas fuel, chemical industry, etc., can solve the problems of high investment and operation cost, low conversion efficiency of alkane gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

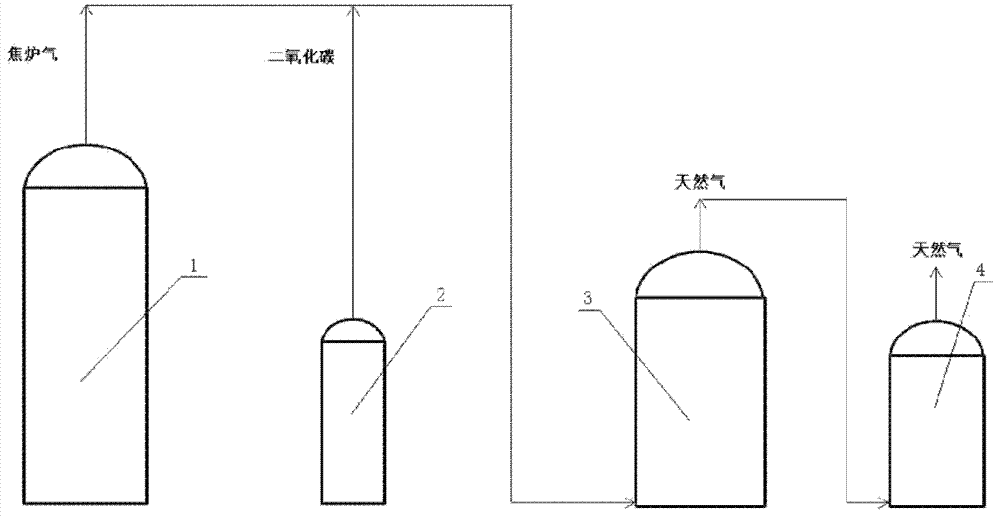

Image

Examples

Embodiment 1

[0023] With 1 volume of coke oven gas (H 2 Content 60%, CO content 8%, CH4 content 25%, CO 2 Content 3%), with 0.06 volume of CO 2 Mixed, passed into the high temperature (55 ℃) CSTR anaerobic reactor, the microorganisms were inoculated with the sludge of the high temperature anaerobic reactor for cow dung, and the highly active anaerobic microorganisms had passed through the H 2 , CO, CO 2 The substrate was pre-acclimated and cultured in a nutrient salt liquid medium containing peptone and dipotassium hydrogen phosphate. The reactor was mechanically stirred at a stirring speed of 400rpm. The residence time of the mixed gas in the reactor is controlled at 1 hour, and every 1.07 volume of the mixed gas can produce about 0.5 volume of the mixed gas, wherein the methane content is about 90%. The resulting mixed gas is further purified through pressure swing adsorption separation to obtain natural gas with a methane content of more than 98%.

Embodiment 2

[0025] With 1 volume of coke oven gas (H 2 Content 60%, CO content 8%, CH4 content 25%, CO 2 Content 3%), with 0.06 volume of CO 2 Mixed, passed into the medium temperature (35 ℃) upflow anaerobic sludge expanded bed reactor (UASB), the microorganisms were inoculated with the medium temperature anaerobic granular sludge, and the highly active anaerobic microorganisms had been passed through the H 2 , CO, CO 2 It was pre-acclimated to the substrate and cultured in nutrient liquid medium containing peptone and dipotassium phosphate. The residence time of the mixed gas in the reactor is controlled at 3 hours, and every 1.07 volume of the mixed gas can produce about 0.45 volume of the mixed gas, wherein the methane content is about 90%. The resulting mixed gas is further purified through cryogenic separation to obtain natural gas with a methane content of more than 98%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com