Water loss reducing agent used for well cementation in deepwater at low temperature and preparation method thereof

A fluid loss reducing agent, low temperature technology, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of low concentration of fluid loss reducing agent, uneconomical transportation, storage and use, uneven mixing, etc. Achieve high effective concentration, save material storage space, and simplify the effect of on-site use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] formula:

[0025] Sodium thiosulfate pentahydrate (Langfang Asia Pacific Longxing Chemical Co., Ltd., industrial grade), 47%;

[0026] Polyvinyl alcohol BP-24 (Taiwan Chunguang Company, industrial grade), 30%;

[0027] The balance is deionized water.

[0028] The method for preparing the fluid loss reducer of the above formula is:

[0029] Add sodium thiosulfate pentahydrate and water into the reaction kettle and stir to dissolve, then slowly add polyvinyl alcohol and stir evenly to obtain the fluid loss reducer for low-temperature well cementing in deep water.

[0030] The measured solid content of the fluid loss reducer was 60% (mass percentage), consistent with the calculated value. The fluid loss reducer is effective when used immediately after preparation. However, the fluid loss reducer is easy to segregate, and there will be stratification after a period of time, so it is not suitable for long-term storage and use.

Embodiment 2

[0032] formula:

[0033] Polyether defoamer Basopur DF5 (German BASF company), 0.5%;

[0034] Xanthan gum XC-CH (Hebei Xinhe Biochemical Co., Ltd., industrial grade), 0.2%;

[0035] Sodium thiosulfate pentahydrate (Langfang Asia Pacific Longxing Chemical Co., Ltd., industrial grade), 47%;

[0036] Polyvinyl alcohol BP-24 (Taiwan Chunguang Company, industrial grade), 30%;

[0037] Sodium benzoate (Tianjin Xin Dayu Chemical Co., Ltd., industrial grade), 0.3%;

[0038] The balance is deionized water.

[0039] The method for preparing the fluid loss reducer of the above formula is:

[0040] Weigh deionized water and xanthan gum, and at room temperature, dissolve xanthan gum in water in a reactor with a stirring device, completely dissolve and increase viscosity, then add polyether defoamer Basopur DF5 and stir evenly, Add sodium thiosulfate pentahydrate and stir to dissolve. After fully stirring and dissolving, add polyvinyl alcohol and stir evenly, add sodium benzoate and st...

Embodiment 3

[0043] The fluid loss reducer (named G72LA, prepared according to Example 2) of the application for deepwater low-temperature cementing was combined with the G72S fluid loss reducer in the traditional powder form (purchased from Tianjin Zhonghai Oilfield Chemical Co., Ltd.) and the G72L in liquid form ( purchased from Tianjin Zhonghai Oilfield Chemical Co., Ltd.) for performance testing.

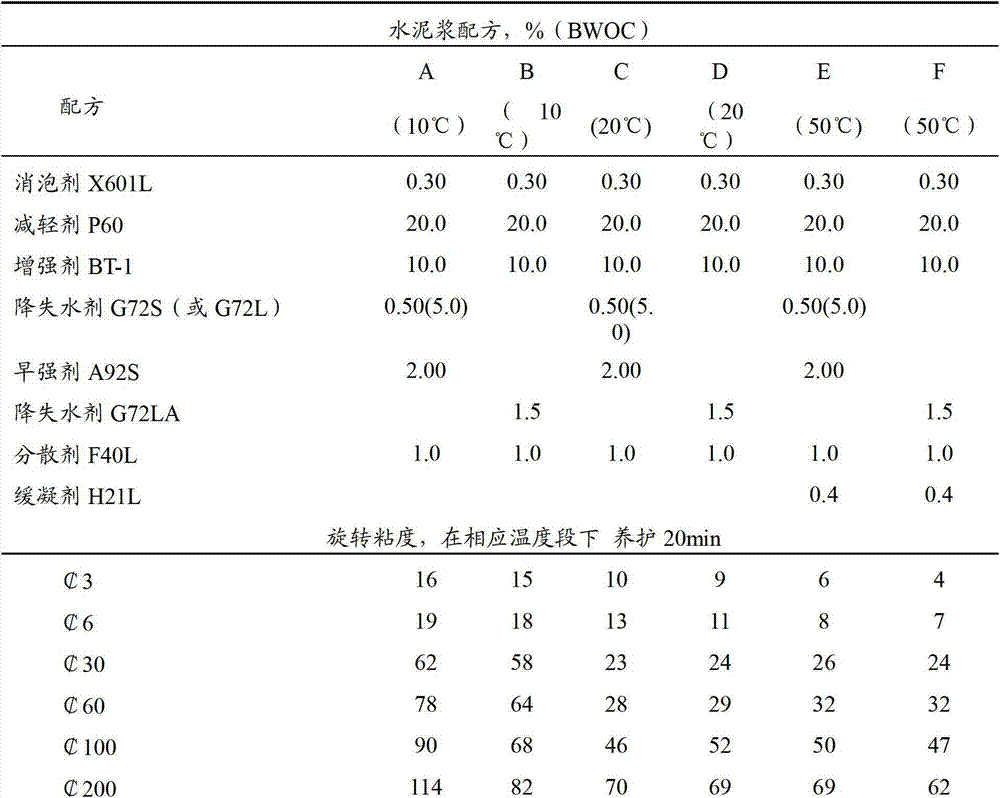

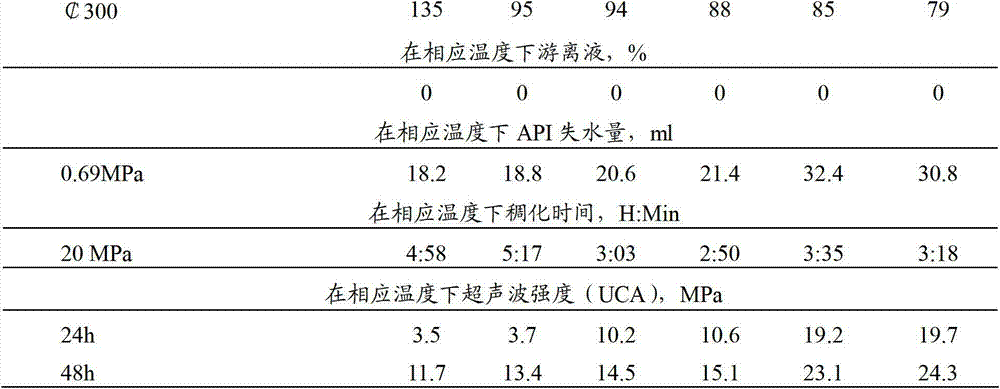

[0044] Table 1 lists the cement slurry properties measured under the conditions of 10°C, 20°C and 50°C using G72LA fluid loss reducer of the present application, G72S fluid loss reducer in traditional powder form and G72L in liquid form.

[0045] Table 11.50S.G Cement Slurry Formula and Performance Evaluation

[0046]

[0047]

[0048] Note: 1. BWOC is the amount of other admixtures calculated based on the weight percentage of cement;

[0049] 2. X601L is ether defoamer, G72S is traditional PVA fluid loss reducer, G72L is traditional liquid PVA fluid loss reducer (effective concentrat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| alcoholysis degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com