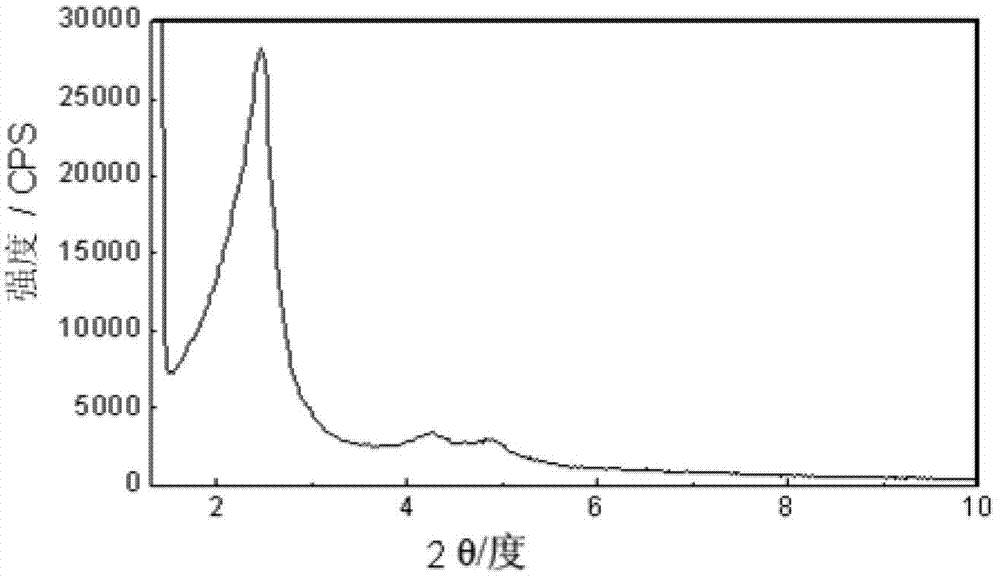

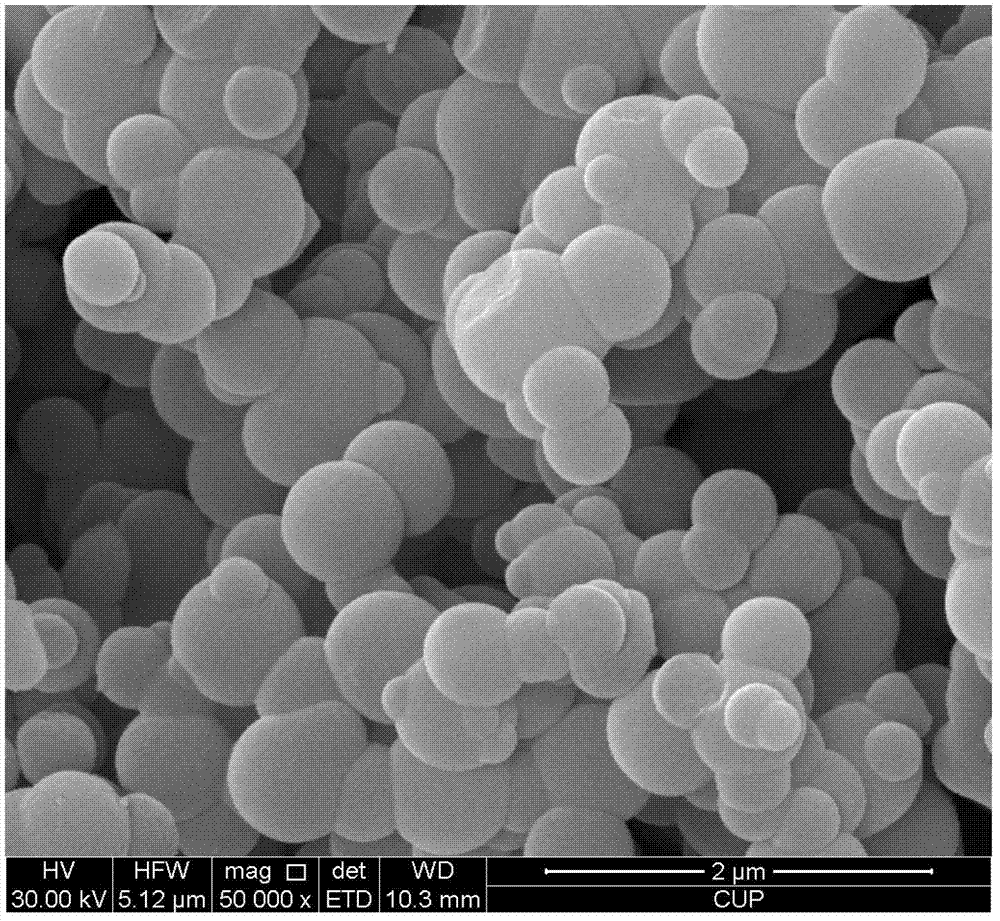

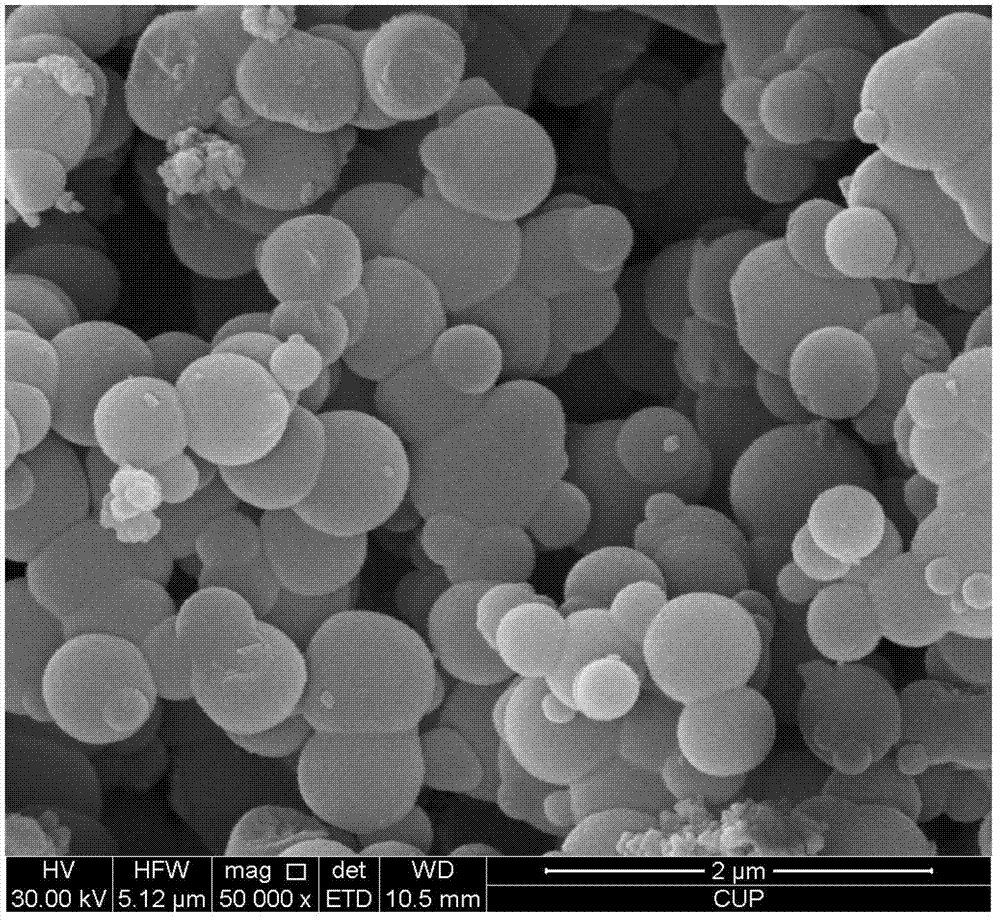

Silicon-based mesoporous material and preparation method thereof

A technology for silicon-based mesoporous materials and raw materials, applied in the field of chemistry, can solve the problems of difficult coordination, low degree of ordering, and higher price of silylation reagents, and achieves good coordination removal effect and improved ordering degree. , the effect of improving similarity compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a method for preparing the aforementioned silicon-based mesoporous material, comprising:

[0047] Weigh raw materials according to the amount of raw materials added;

[0048] mixing absolute ethanol and water to prepare the first mixed solution;

[0049] Adding a quaternary ammonium salt type cationic surfactant to the first mixed solution to prepare a second mixed solution;

[0050] Adding β-alanine to the second mixed solution to prepare a third mixed solution;

[0051] Add ammonia water to the third mixed solution to prepare the fourth mixed solution;

[0052] Ethyl orthosilicate was added into the fourth mixed solution to prepare a silicon-based mesoporous material.

[0053] Using quaternary ammonium cationic surfactant as template, ethyl orthosilicate as silicon source, and adding β-alanine, the order degree of the material synthesized under weak alkaline conditions is significantly improved, and the material contains ammonia ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com