Light stacking robot pallet fork device

A stacking robot, light-weight technology, applied in the direction of lifting devices, etc., can solve the problems of reduced work efficiency and stability, large motion noise, poor positioning accuracy, etc., to improve work stability and production efficiency, reduce weight, and improve efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following describes the implementation of the present invention in detail with reference to the drawings and embodiments.

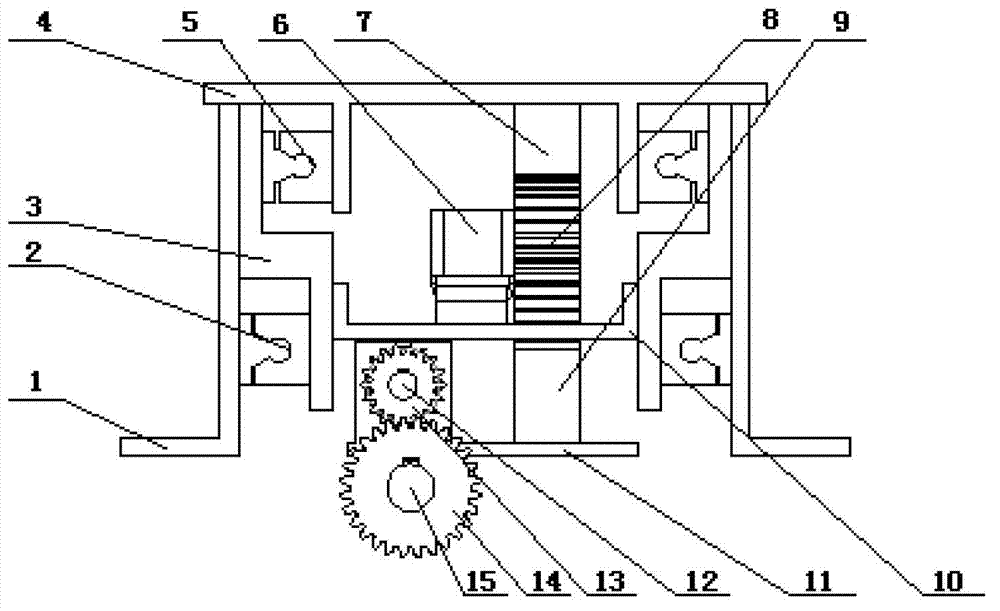

[0019] Such as figure 1 Shown is a schematic diagram of the overall structure of the stacking robot fork device. The system is mainly composed of upper fork 4 and upper fork slide 5, middle fork 3 and middle fork connecting plate 10, lower fork 1 and lower fork slide 2, gear It is composed of rack differential mechanism and screw mechanism. figure 2 versus image 3 The structure of the stacking robot fork device is shown from different directions.

[0020] The detailed structure and working principle of the stacking robot fork device are as follows: the motor shaft 15 connected to the motor forms a fixed connection with the motor gear 14 through the keyway and the key on the shaft, thereby driving the motor gear 14 to rotate, and the screw gear 13 and the wire The rod 12 is also fixedly connected by the cooperation of the keyway and the key on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com