Sample automatic random racking machine suitable for multi-item cigarette inspection

A packaging machine, sample technology, applied in the direction of packaging automatic control, packaging, packaging cigarettes, etc., can solve the problems of complex sorting and inspection, high labor intensity, human error, etc., and achieve the effect of expanding flexibility, reducing labor intensity and improving speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

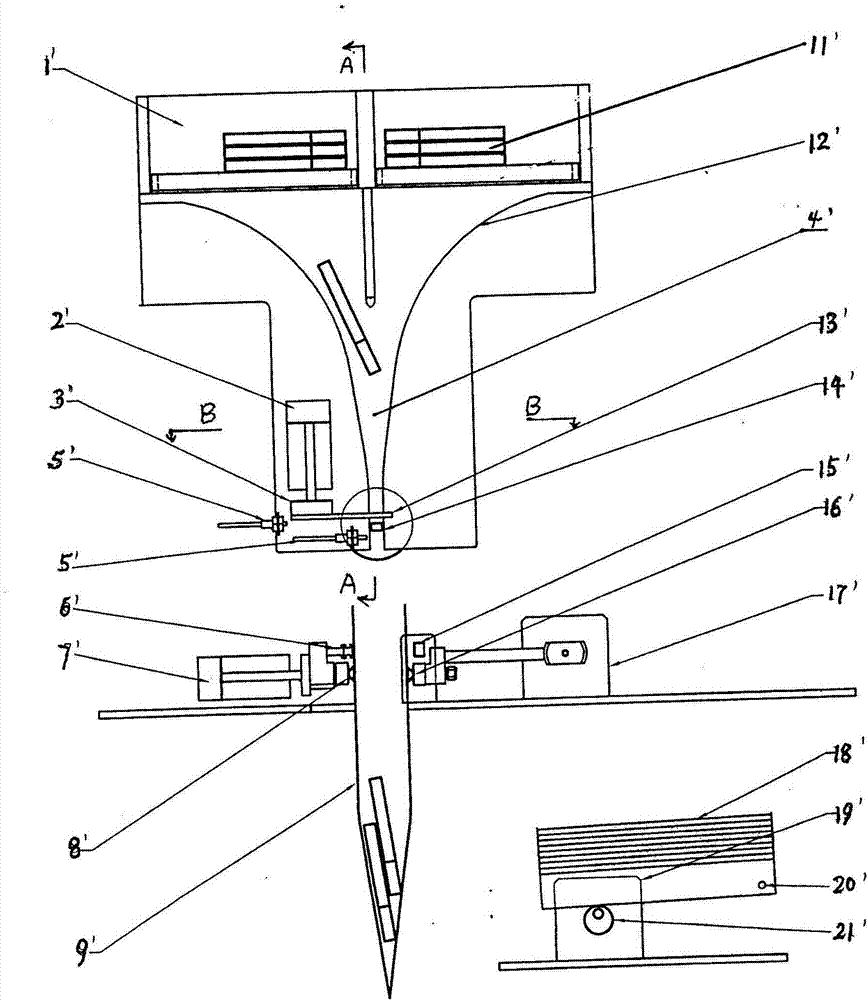

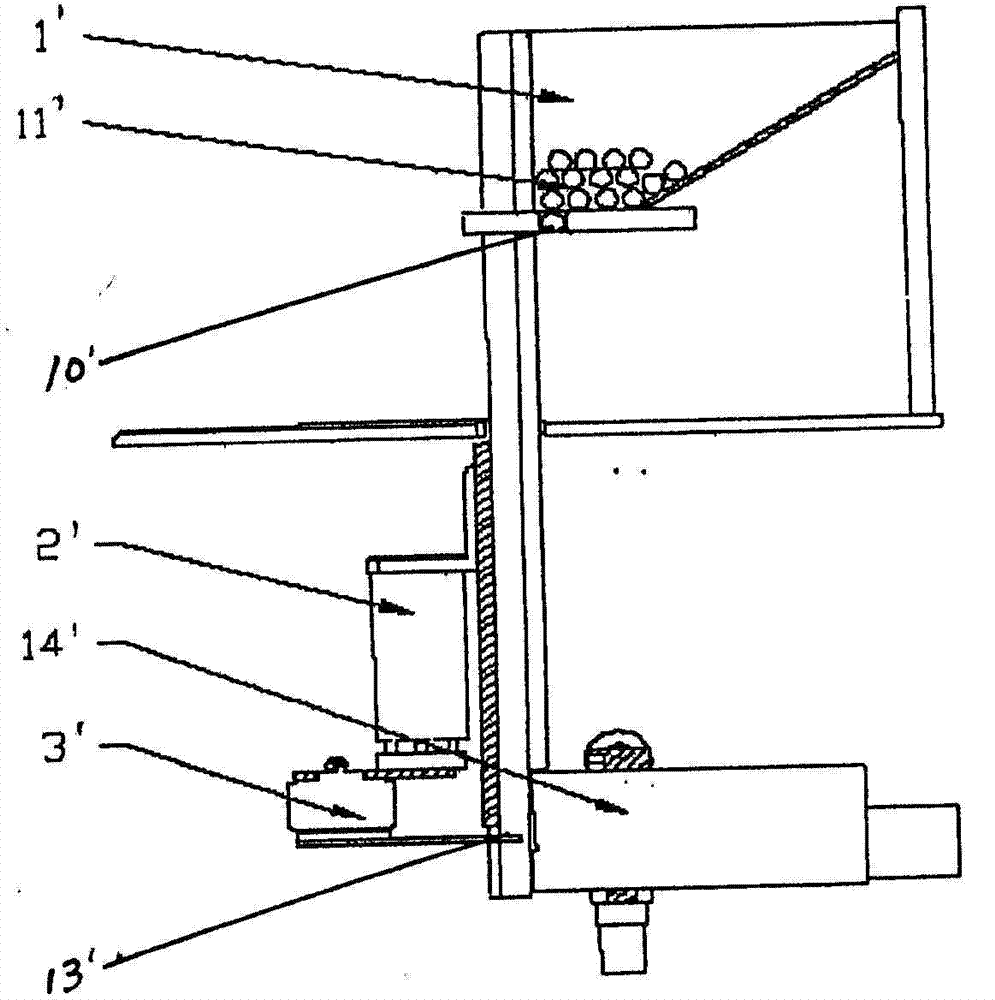

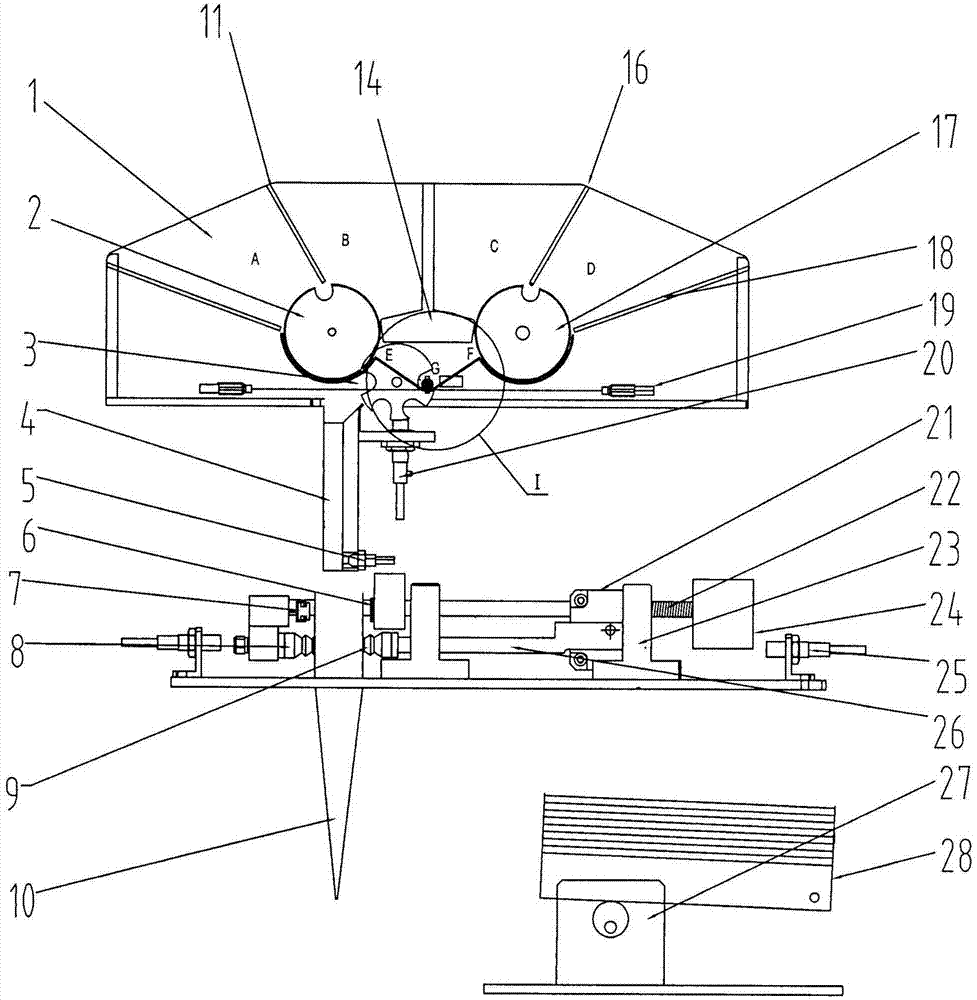

Method used

Image

Examples

Embodiment 1

[0074] Task: A cigarette company has adjusted the formula of a certain specification of cigarettes, and needs to conduct a three-point inspection on the products before and after the adjustment. Assume that the sample before adjustment is A, the sample after adjustment is B, and there are 6 inspectors.

[0075] 1). The sample size is set to 6, and the software system automatically produces the cigarette composition and coding scheme, examples are as follows:

[0076]

[0077] 2). After loading 20 A and B cigarettes into the A hopper and the D hopper respectively, start the device.

[0078] 3). The sample bag conveying mechanism takes out a sample bag from the sample bag box and moves it to the vertical position; the bag taking, bag opening and heat sealing mechanism opens the sample bag; starting from the 01 sample, through signal control, the right roller of the hopper rotates to take a sample bag A cigarette is sent to the rotary pushing area, and then pushed into the...

Embodiment 2

[0081] Task: A cigarette company has adjusted the formula of a certain specification of cigarettes, and needs to conduct a three-point inspection on the products before and after the adjustment. Assume that the sample before adjustment is A, the sample after adjustment is B, and the number of inspectors is 30.

[0082] The sample size is set to 30, and the software system automatically produces the cigarette composition and coding scheme, examples are as follows:

[0083]

[0084] 2). After loading 60 cigarettes into A and B cigarettes respectively in the A hopper and the D hopper, start the device.

[0085] Same as 3) and 4) above, complete the preparation of 01, 02, 03...30 samples.

Embodiment 3

[0087] A cigarette company uses the three-point test method to evaluate the sensory quality consistency of licensed products of cigarettes of multiple specifications. Assume that a three-point test needs to be carried out on 10 specifications of cigarette products, and the number of testers is 30 people.

[0088] 1). Set the number of inspection specifications to 10 and the sample size to 30, and the software system will automatically produce the composition and coding scheme of cigarettes. The example is as follows:

[0089]

[0090]

[0091]

[0092] 2). After loading 60 A and B cigarettes of specification 1 into the A hopper and the D hopper respectively, start the device.

[0093] Same as 3) and 4) above, complete the preparation of 01, 02, 03...30 samples of specification 1, and the first two digits of the codes of all cigarettes in the sample are 01, which means that 30 samples are samples of specification 1. After the completion, replace the A and B cigarett...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com