Aerial ropeway wheel side braking device

A braking device and technology for aerial ropeways, which are used in cable railways, motor vehicles, transportation and packaging, etc., can solve problems such as wear failure, inability to stop the operation of aerial ropeways, and safety accidents.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

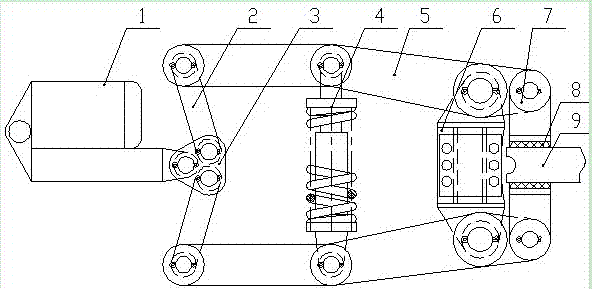

[0009] Below in conjunction with accompanying drawing, the wheel side braking device of aerial ropeway of the present invention will be further described.

[0010] Such as figure 1 As shown, the invention includes an explosion-proof electro-hydraulic pusher 1, a connecting rod 2, a connecting block 3, a compression spring rod 4, a brake arm 5, a base 6, and a brake block 7. This invention is provided with a base 6, and a pair of brake arms 5 are symmetrically hinged up and down respectively on the base 6, and a compression spring rod 4 is connected between the brake arms 5, and one end of each brake arm 5 A corresponding brake block 7 is respectively hinged, and the other end of each brake arm 5 is correspondingly hinged with a connecting rod 2, and the other end of the connecting rod 2 is opposite, and the connecting block 3 is hinged, and the connecting block 3 is connected to the spacer. Explosive electro-hydraulic pusher 1 is hingedly connected. The friction plate 8 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com