Accumulation pressure balance type clutch controller driving method

A technology of a clutch controller and a driving method, which is applied in the directions of control devices, transportation and packaging, vehicle components, etc., to achieve the effects of simple structure, fast deflation speed, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

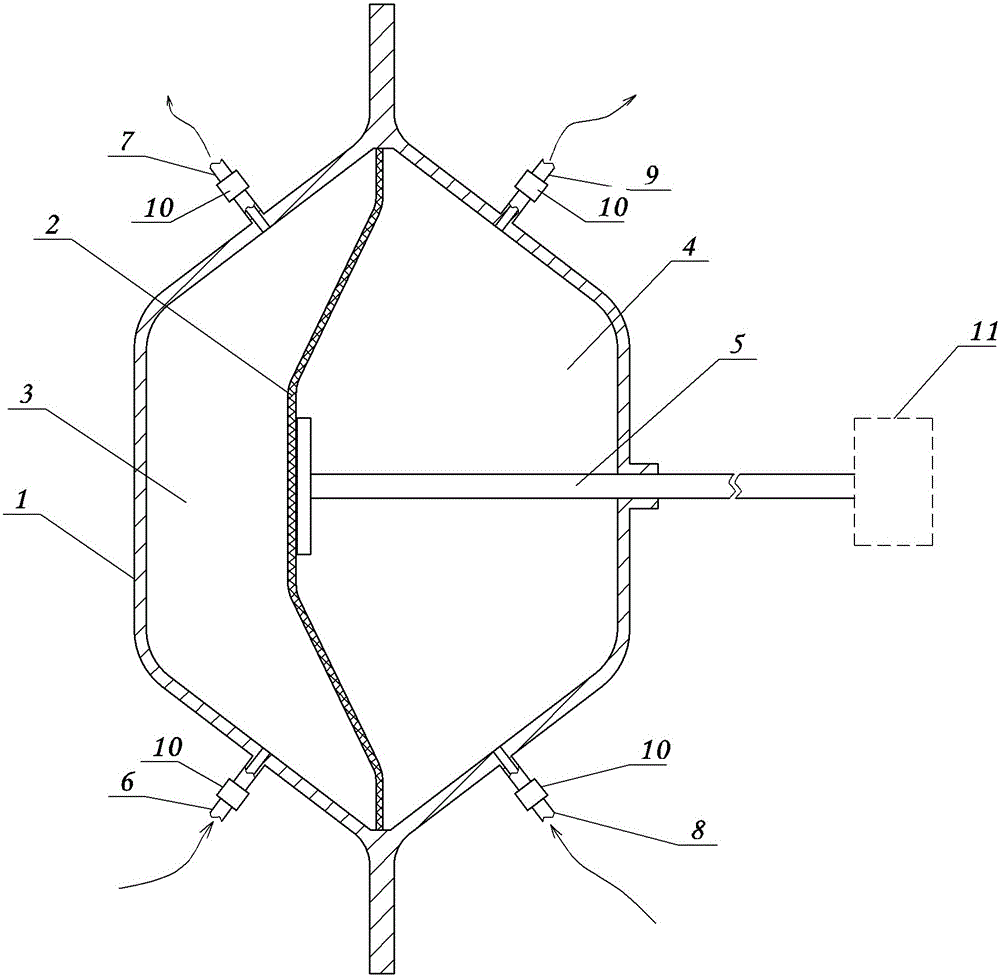

[0009] see figure 1 , a drive method for a pressure-storage balanced clutch controller, using an air film 2 in the air chamber to divide it into a left air chamber 3 and a right air chamber 4, and the outer wall of the right air chamber 4 is provided with a mounting hole and a matching set with a push Rod 5, one end of the push rod 5 is connected with the air film 2, and the other end is connected with the pressure plate of the clutch 11, the air inlet pipe 6 and the air outlet pipe 7 are arranged on the left air chamber 3, and the air inlet pipe 8 and the outlet pipe 7 are respectively arranged on the right air chamber 4. Trachea 9, valve 10 is set respectively on each air intake pipe and air outlet pipe, respectively fills the gas of 8 atmospheres in left air chamber 3 and right air chamber 4 respectively, when needing clutch action, to the outlet of right air chamber 4 The trachea 9 deflates to move quickly, and the right air chamber 4 is inflated after the exhaust, so that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com