Manufacturing method and production device for production line of corrugated fiberboard cushioning pad

A kind of production equipment and corrugated paper technology, applied in the direction of mechanical processing/deformation, etc., can solve the problems of low production efficiency and high labor intensity, and achieve the effects of small footprint, low production cost and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

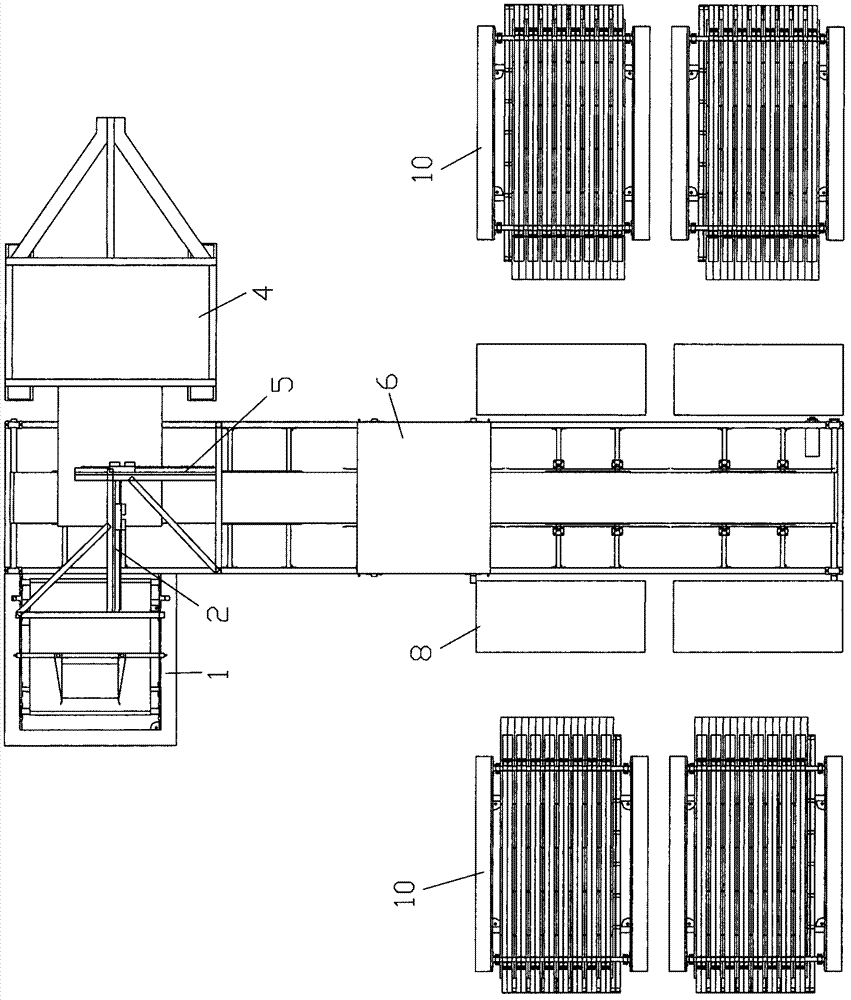

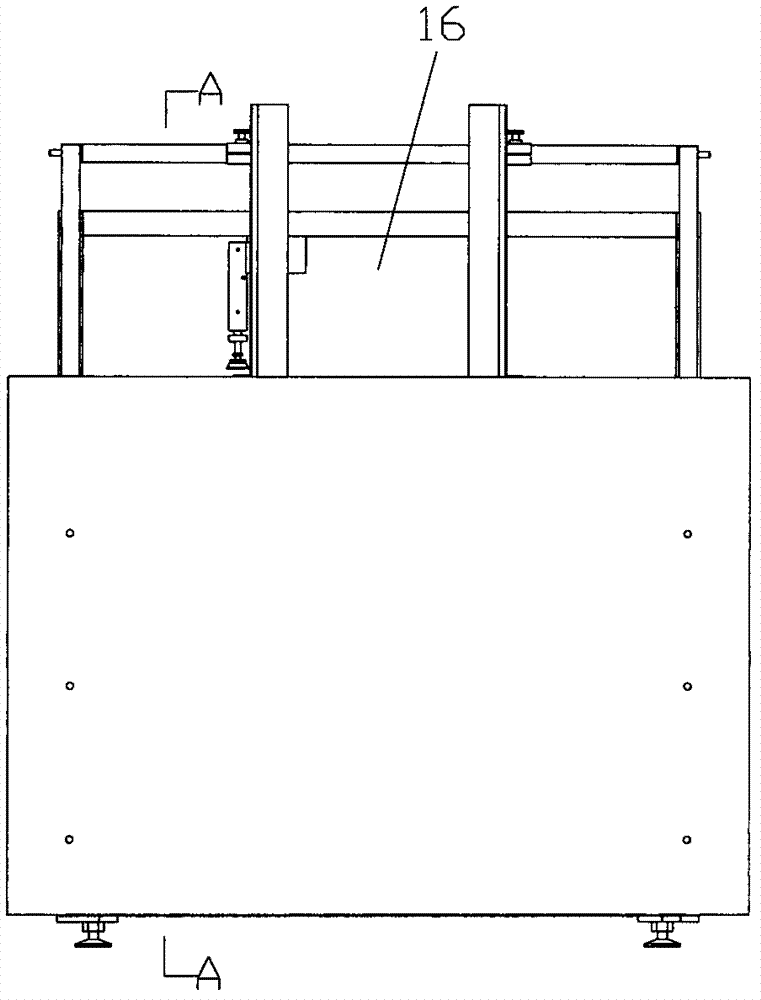

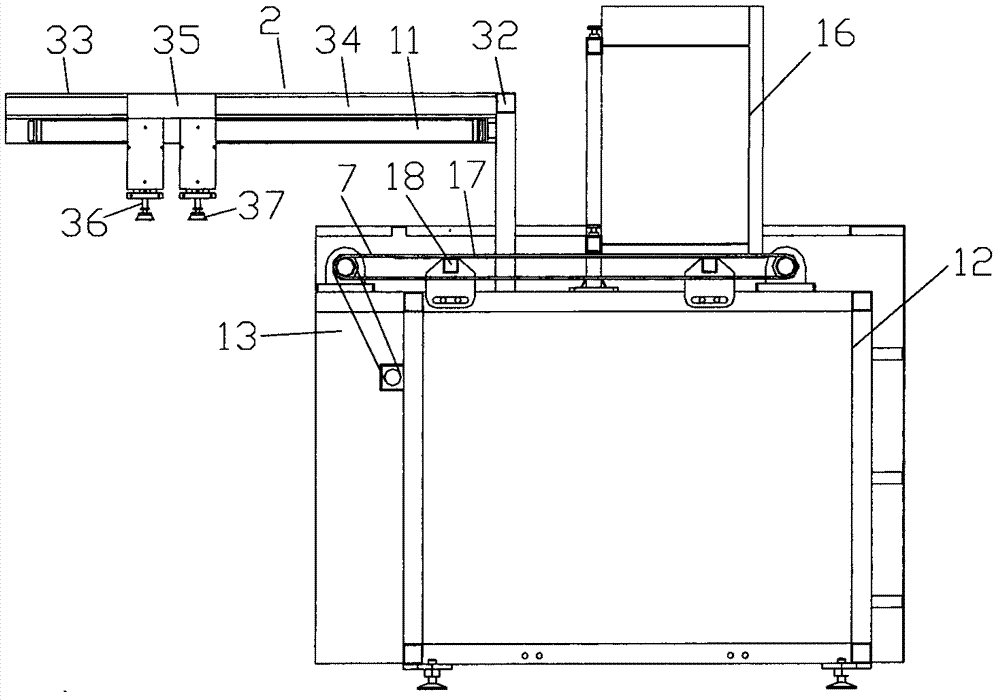

[0035] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0036] The product production method in the production line of corrugated paper buffer liner that the present invention relates to, the method comprises the following steps:

[0037] A. Feeding--place batches of corrugated paper on the feeder 1, through the feeder 1, send each piece of corrugated paper to the discharge end of the feeder 1 one by one through the conveyor belt 7, and place it through the feeding manipulator 2 Blanking work plate 3 position;

[0038] B. Blanking--When the corrugated paper is obtained in step A, the blanking working plate 3 is moved and recovered to the right below the blanking machine 4, the blanking machine 4 is pressed down, and the excess waste is cut off through the blanking mold, and the required bending engrave the upper bending indentation, the blanking work plate 3 returns to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com