Novel optical fiber docking device

A docking device and optical fiber technology, which is applied in the field of optical fiber connection devices, can solve the problems of long-term reliability decline, failure of optical fiber docking, and easy breakage of bare fibers, etc., and achieve the effect of simple structure, high docking quality and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

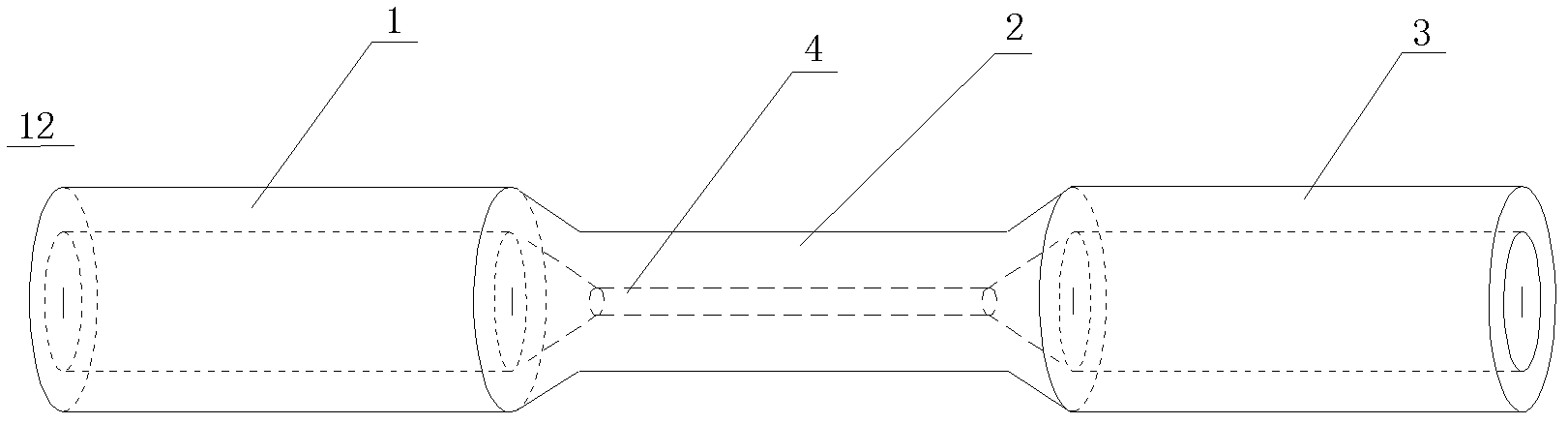

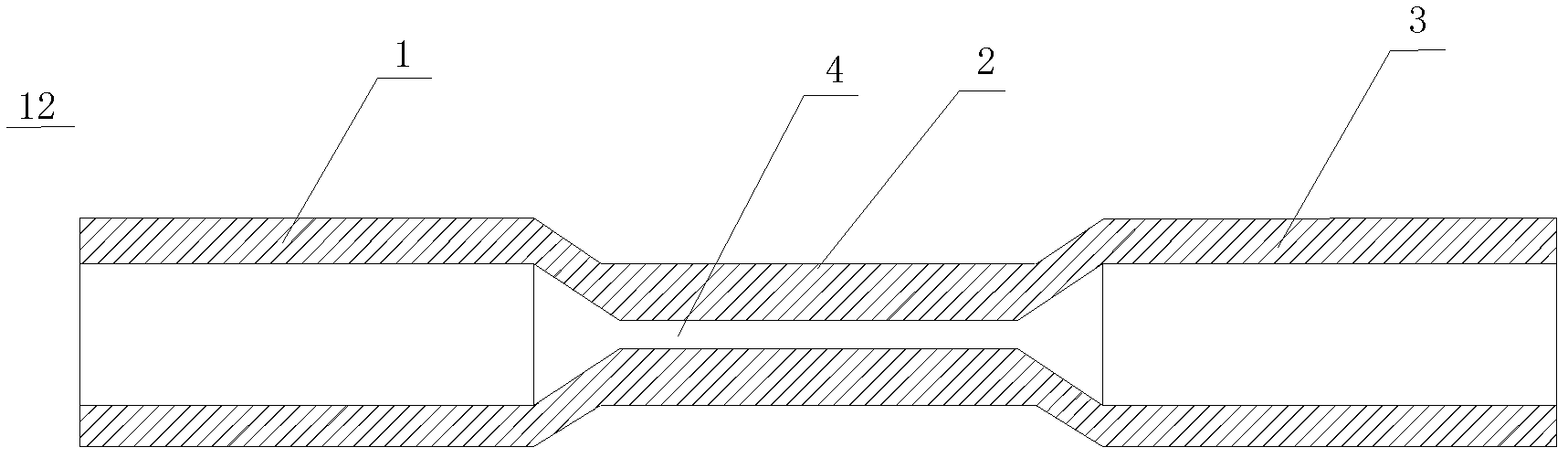

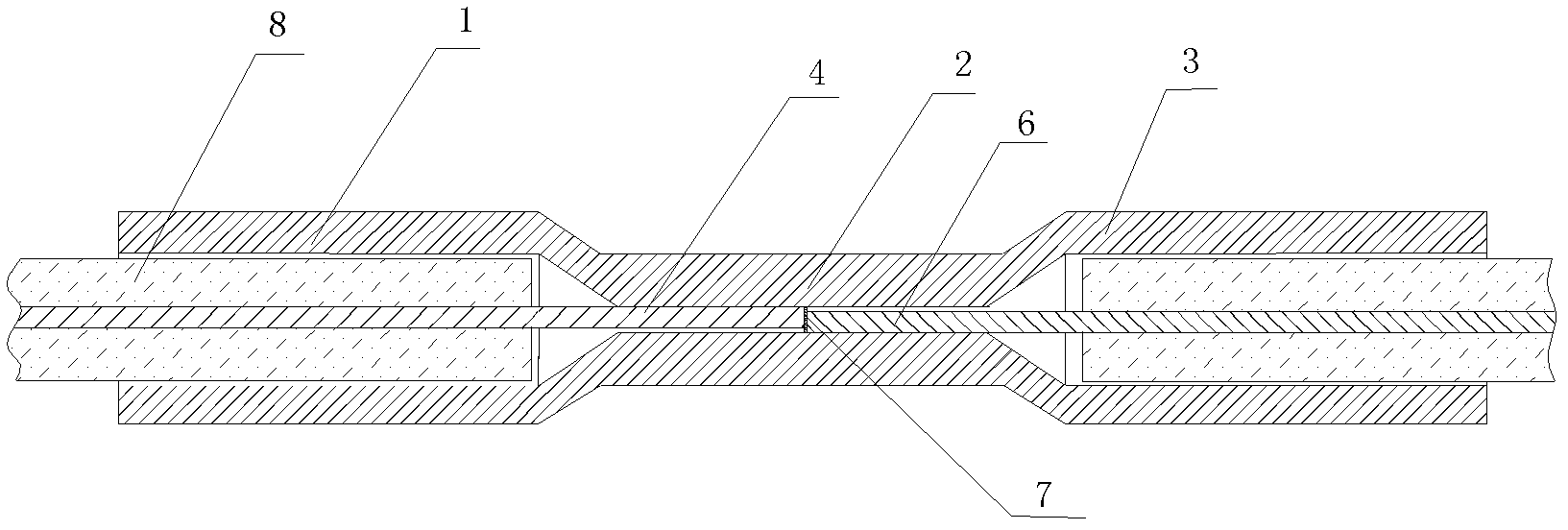

[0043] Such as figure 1 , figure 2 , image 3 and Figure 4 As shown, it includes a fiber optic connector 12 with a tubular structure made of a memory alloy material. In particular, the fiber optic connector 12 is composed of three tubes with different inner diameters, which are the first tube 1 and the second tube 1 respectively. Tube 2 and the third section of tube 3, wherein the inner diameter of the lumen 4 of the second section of tube 2 is the smallest, and its initial inner diameter D T1 , Inner diameter D after low temperature expansion T2 The relationship with bare fiber 6 is:

[0044] [1-(1-S)×K]×D F T1 F (5)

[0045] D. F T2 F ×(1+S×K) (6)

[0046] D. F is the outer diameter of the bare optical fiber 6 when docking, K is the shape memory strain coefficient of the optical fiber connector 12 made of memory alloy material, and S is a selected proportional coefficient.

[0047] The inner diameter of the first tube 1 and the third tube 3 of the optical f...

Embodiment 2

[0066] Such as Figure 6 As shown, in this embodiment, the difference from Embodiment 1 is that there is a sleeve 11 outside the tubular structure made of memory alloy.

[0067] Preferably, there is a filler 15 between the sleeve 11 and the tubular structure made of memory alloy.

[0068] Preferably, the filler 15 is a material with good thermal conductivity. Such as thermal silica gel, thermal grease, thermal resin.

[0069] Preferably, the filler 15 has adhesive properties.

[0070] In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

Embodiment 3

[0072] Such as Figure 7 As shown, in this embodiment, the difference from Embodiment 1 is that both ends of the optical fiber connector 12 have tapered inlets 10 . This structure can facilitate the introduction and docking of the bare optical fiber 6 . In this embodiment, the structures, connections and working principles of other parts are the same as those in Embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com