Safety self-locking quick joint

A self-locking and fast technology, applied in mechanical equipment, couplings, etc., can solve the problems of lack of self-locking device, insufficient stability, and no safety effect, and achieve high work efficiency and good sealing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

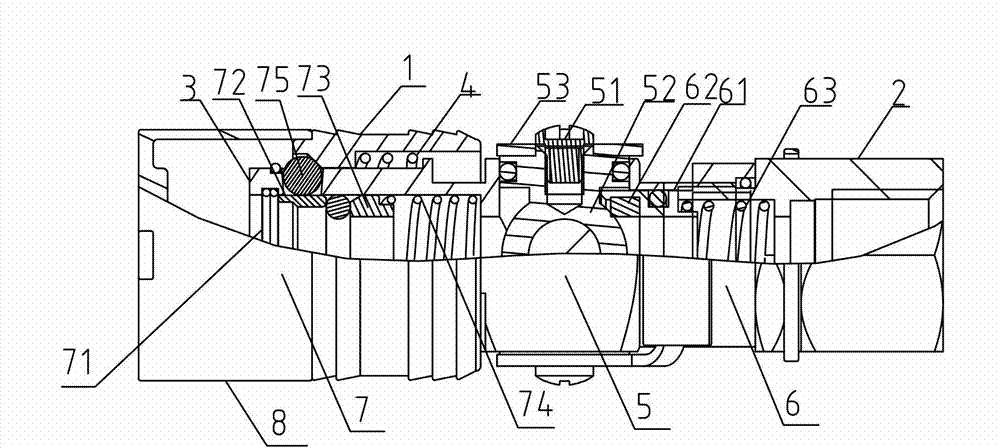

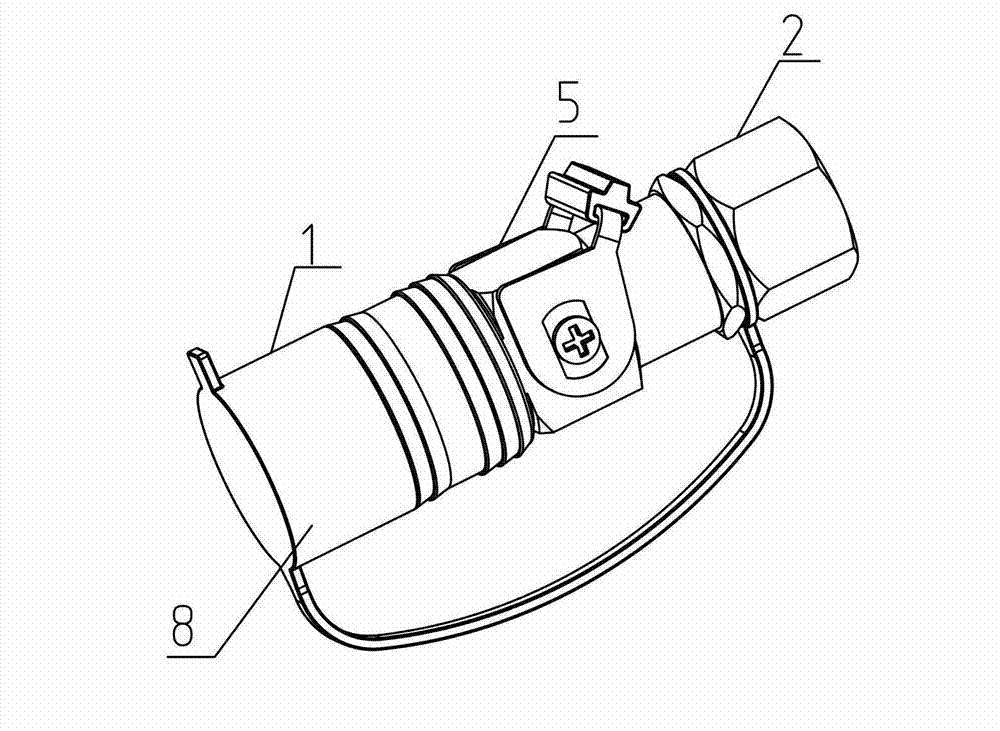

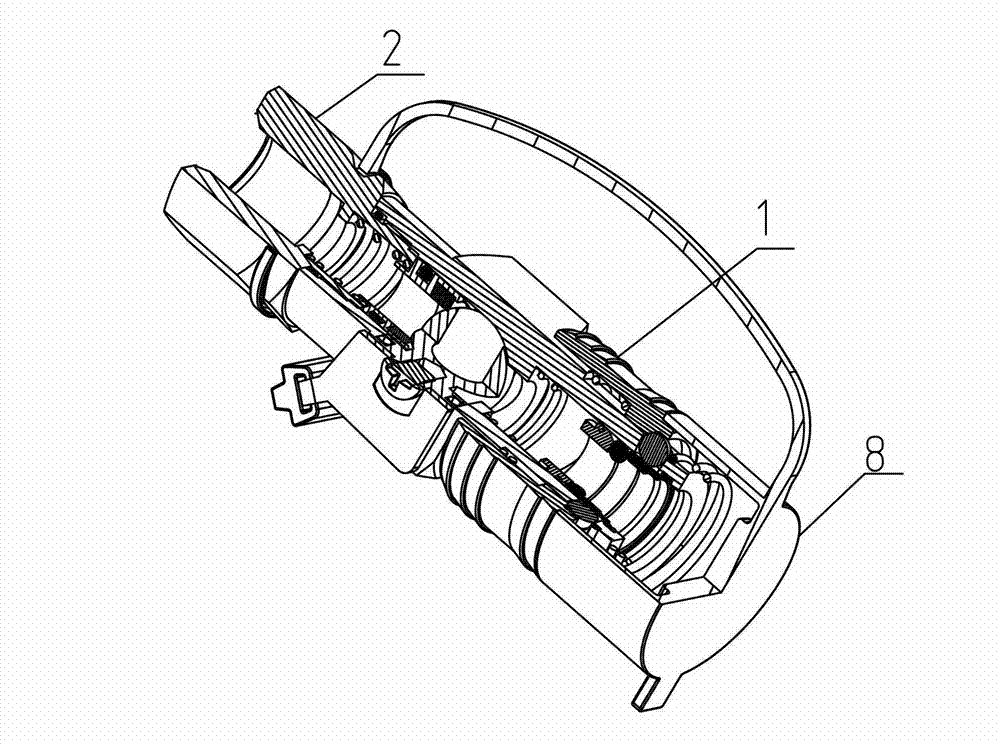

[0014] Such as figure 1 , figure 2 , image 3 As shown, a safety self-locking quick connector includes a quick-connect outer cover 1 and a connecting screw 2, an inner sleeve 3 is provided on the inner wall of the quick-connect outer cover, and a first spring 4 is set on the inner cover, and the quick-connect outer cover 1 is connected to the inner sleeve. The sleeve 3 moves relative to the axial direction. As an improvement of the present invention, a ball valve 5 is provided between the quick-connect outer sleeve 1 and the connecting screw 2. One end of the ball valve 5 is sealed with the inner sleeve 3, and the other end of the ball valve 5 is passed through a sealing device. 6 is sealed and connected with the connecting scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com