Open-air drilling coal cutter

A coal shearer and drill-type technology, which is applied in the field of drill-type coal shearers, can solve the problems of high cost per ton of coal and high labor intensity of workers, and achieve the effects of reducing cost per ton of coal, reducing labor intensity of workers, and easy machine relocation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further explained below in conjunction with the accompanying drawings.

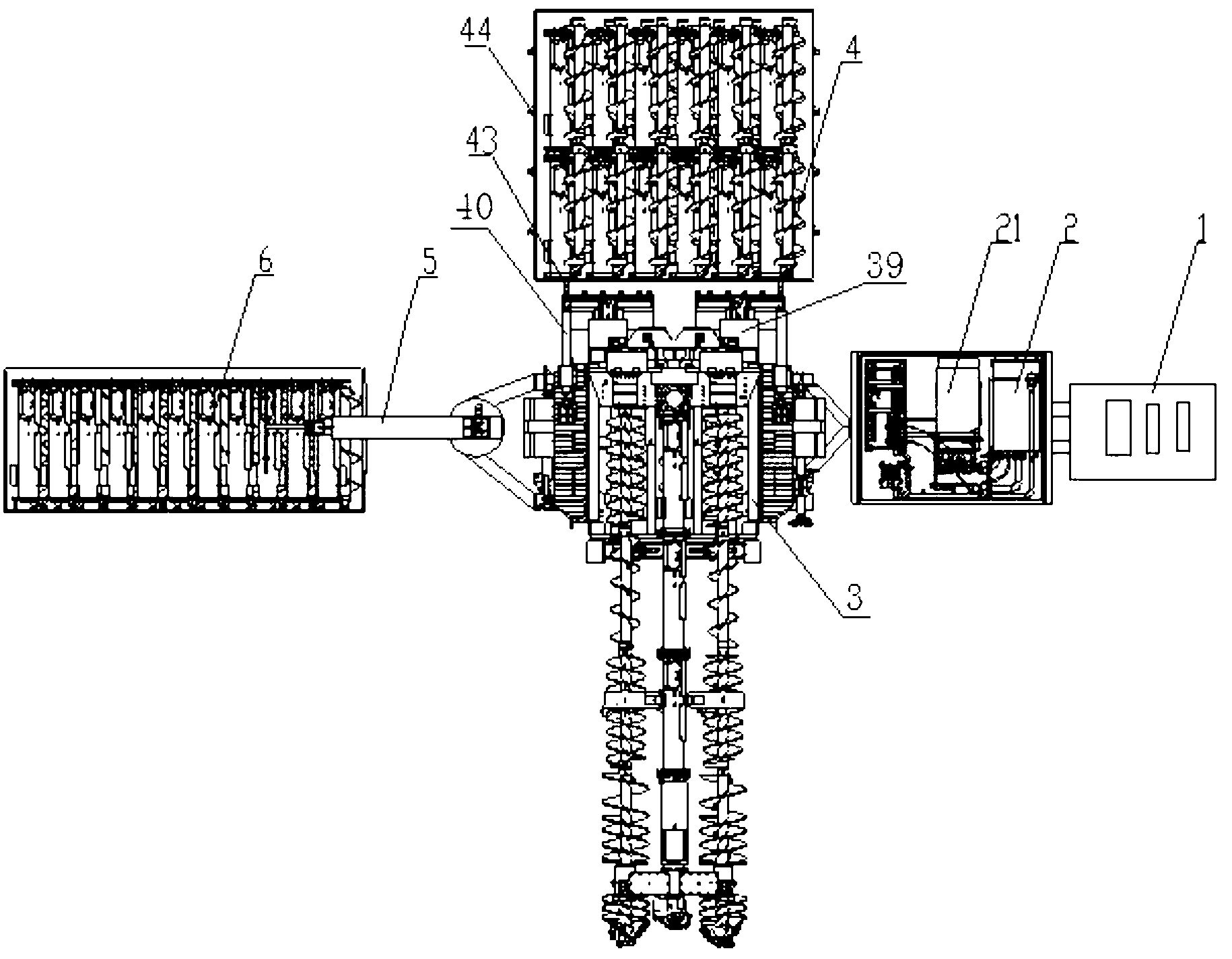

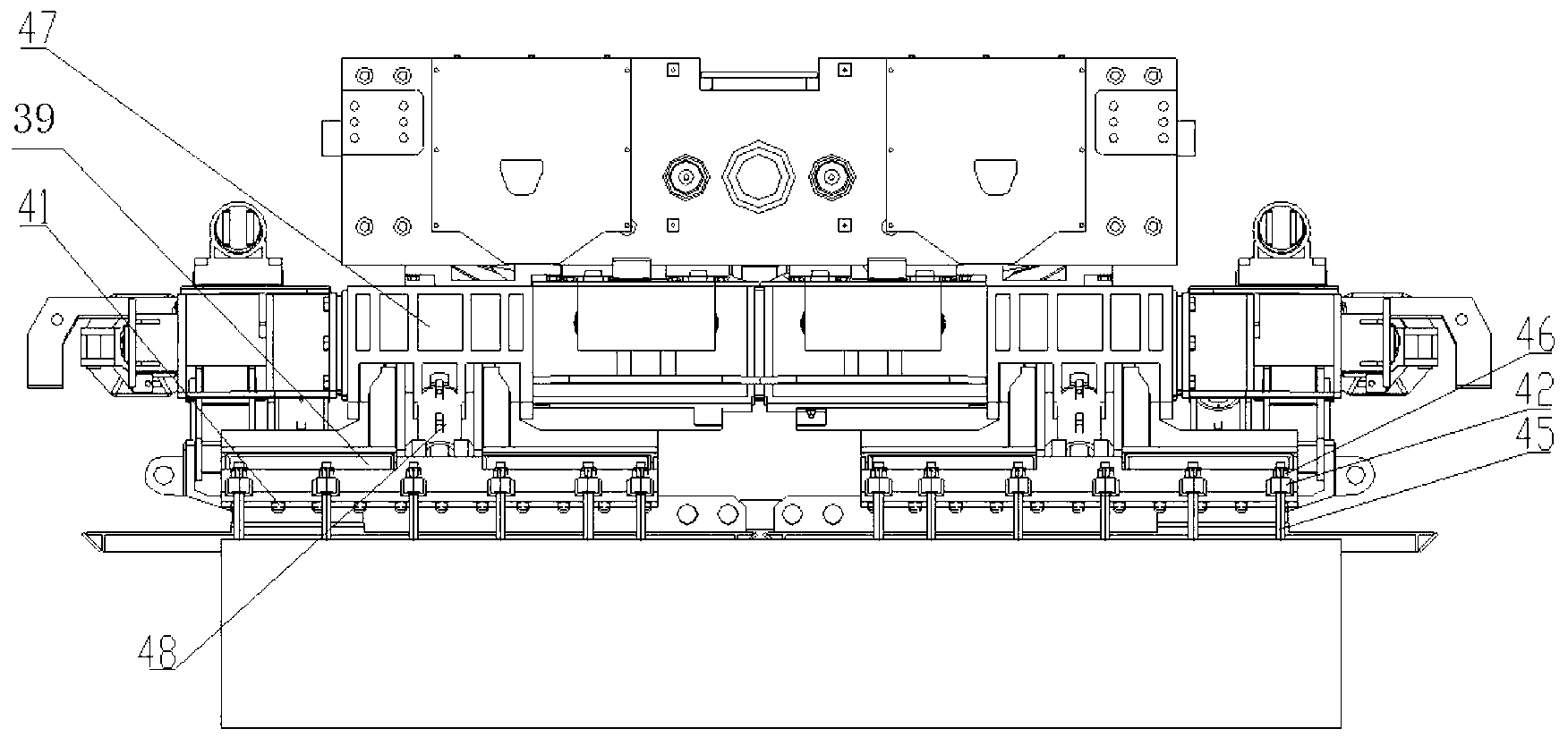

[0018] Such as Figures 1 to 5 As shown, the open-pit mining shearer of the present invention includes a generator set 1, a mobile pump station 2, a main engine 3, a backseat drill rod warehouse 4, a telescopic boom type auxiliary transport device 5 and a main drill rod warehouse 6.

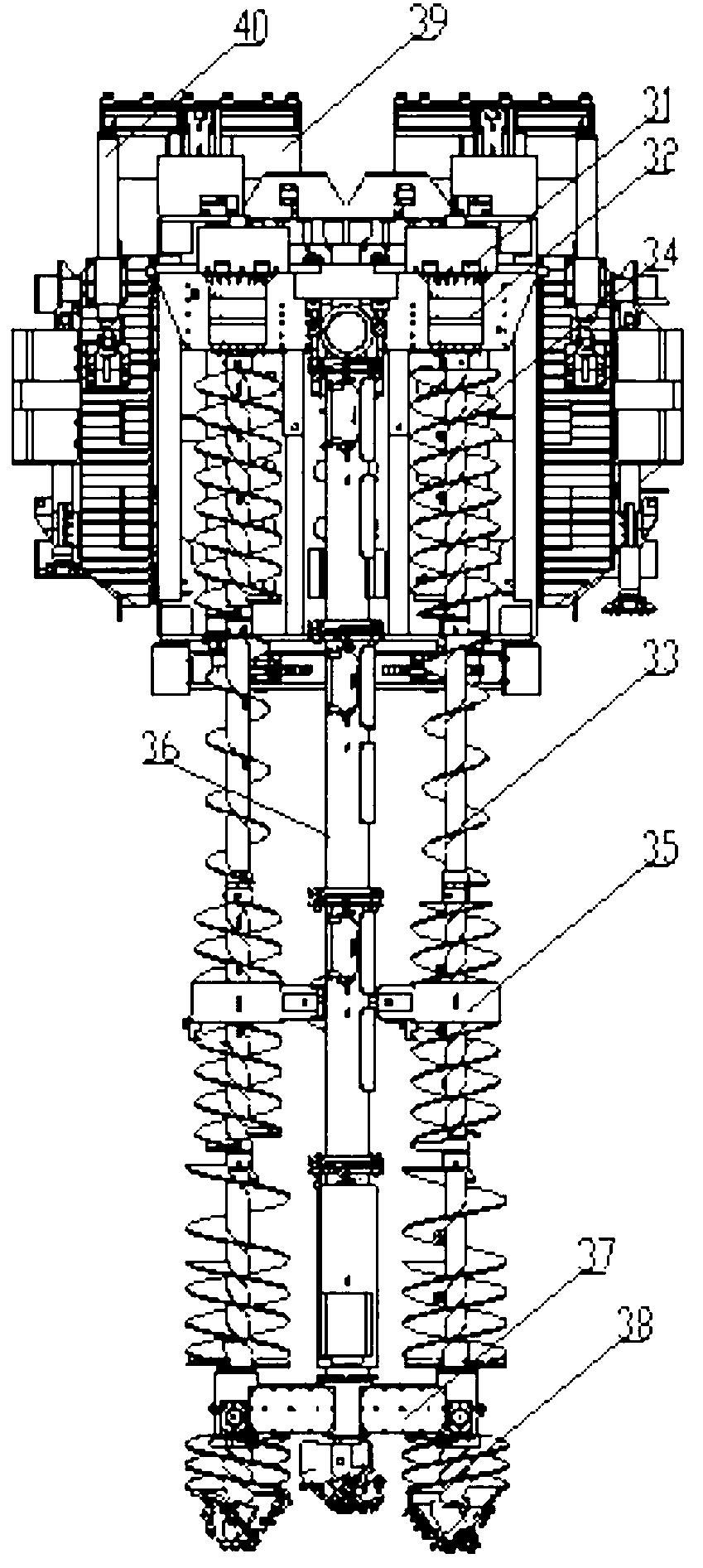

[0019] Main frame 3 comprises two drill rod drive motors 31, each drill rod drive motor 31 all connects the input shaft of front transmission box 37 by a drill rod mechanism, is provided with drill bit 38 on the output shaft of front transmission box 37, and two An intermediate ventilation pipe 36 is provided between the drilling rod mechanisms. Drill rod mechanism is made up of drive reducer 32, middle long drill rod 33, double helix conveying drill rod 34 and stabilizer 35.

[0020] At the afterbody of the main engine 3, a backseat drilling rod storehouse 4, a rear palm bolt support 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com