Rigid pavement deflection test device and test method thereof

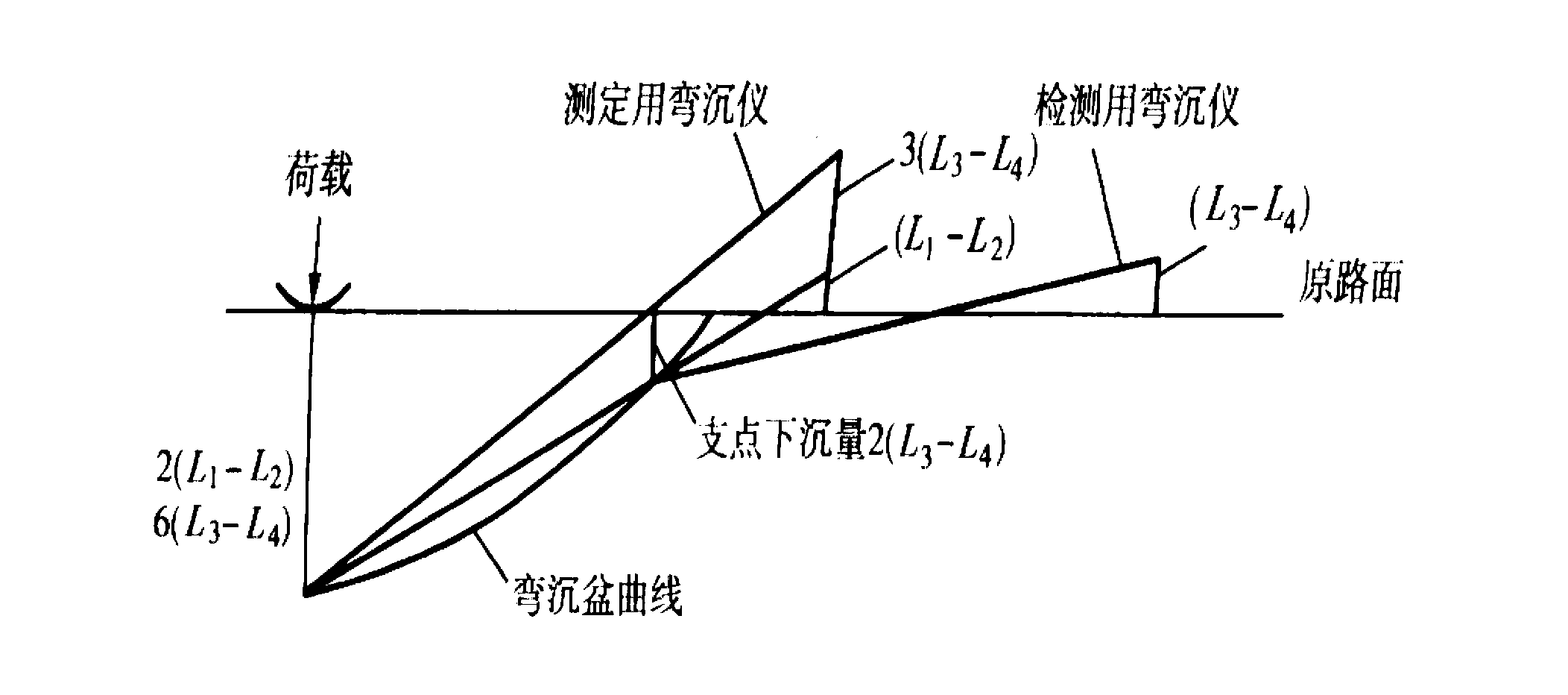

A pavement deflection and testing device technology, applied in roads, roads, road repairs, etc., can solve the problem that the radius of the deflection basin increases, the shape of the deflection basin cannot reflect the dynamic characteristics of the pavement structure, and the dynamic deflection value of the road cannot be measured and other issues, to achieve the effect of easy assembly and disassembly, easy to carry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

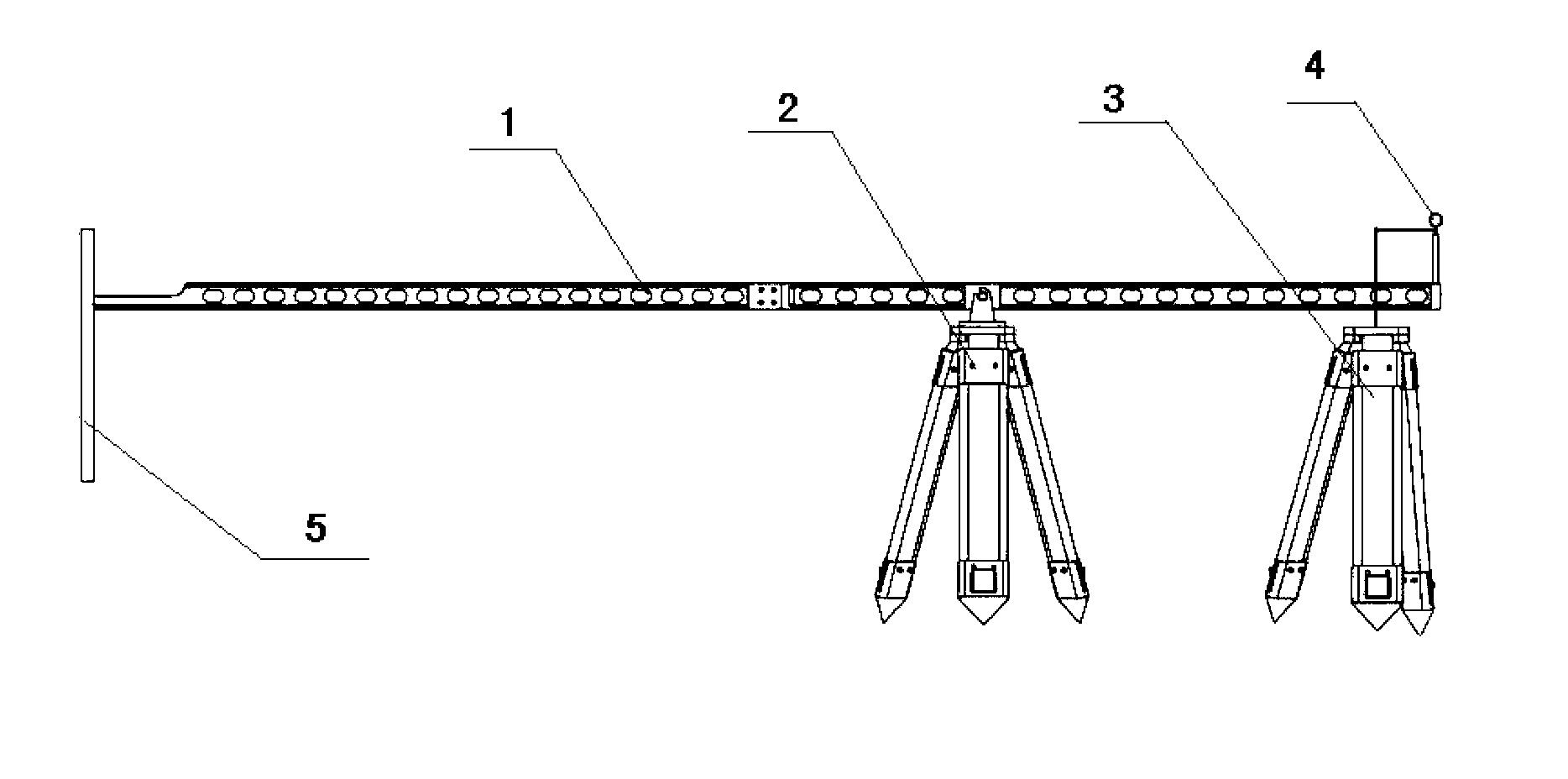

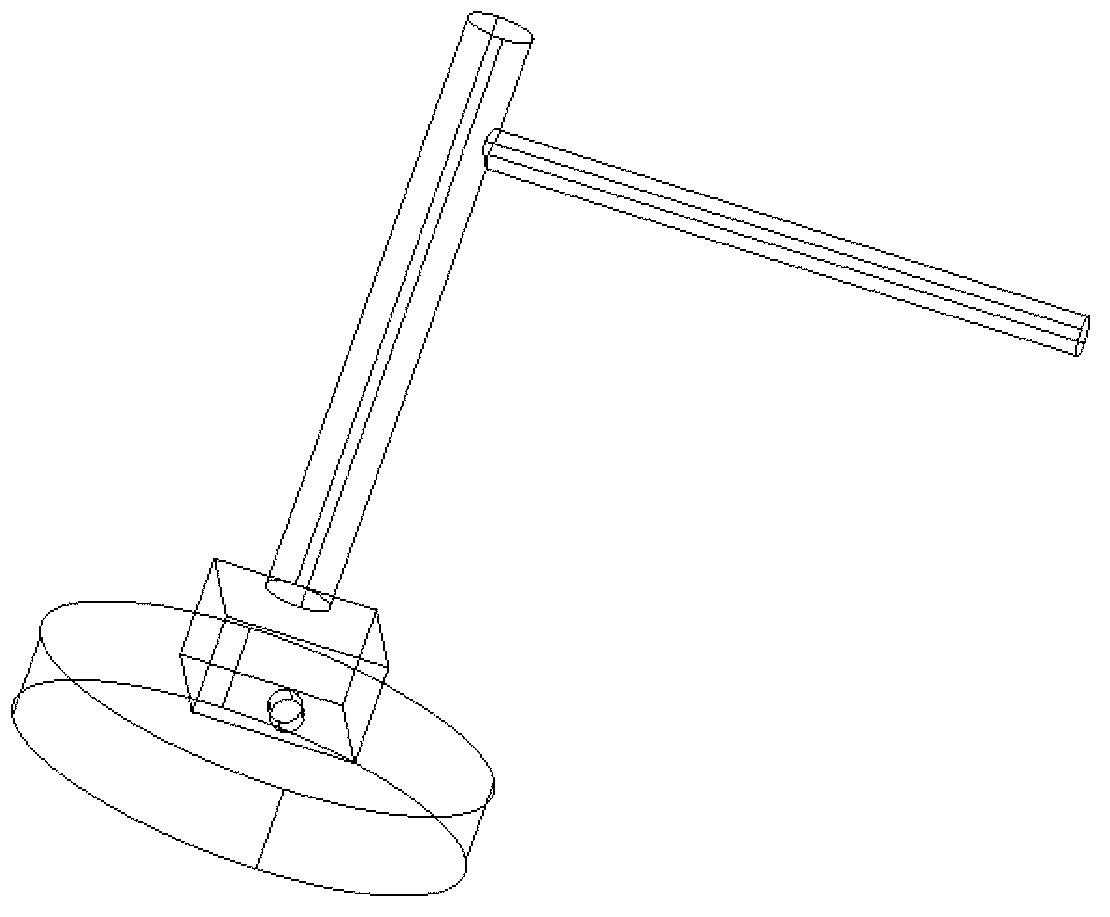

[0030] refer to figure 2 , is the rigid pavement deflection test device of the present invention, mainly comprising Beckman beam 1, the probe 5 that is arranged on the front end of Beckman beam 1, the support that is arranged in the middle of Beckman beam 1, the height of the fixed support is adjustable and the dial indicator 4 arranged at the rear end of the Beckman beam 3, the instrument frame for fixing the dial indicator 4, and the height-adjustable auxiliary tripod 3 for fixing the instrument frame. Among them, the Beckman beam 1 is 5.4m long and made of aluminum alloy. The length ratio of the forearm to the rear arm is 2:1; The adjustable height of the auxiliary tripod 3 is also 500mm-1500mm. The dial indicator 4 adopts the existing Beckman beam dial indicator. instrument rack such as image 3 As shown, its height and direction can be adjusted to adapt to complex road conditions.

[0031] refer to Figure 4 , the support includes a fixed plate 6 connected to the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com