Multi-station full-automatic ore conveying equipment

A fully automatic, multi-station technology, used in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of fixed transportation stroke, low operation efficiency, large floor space, etc., to achieve high transportation efficiency, prevent ore The effect of scattering and saving system floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

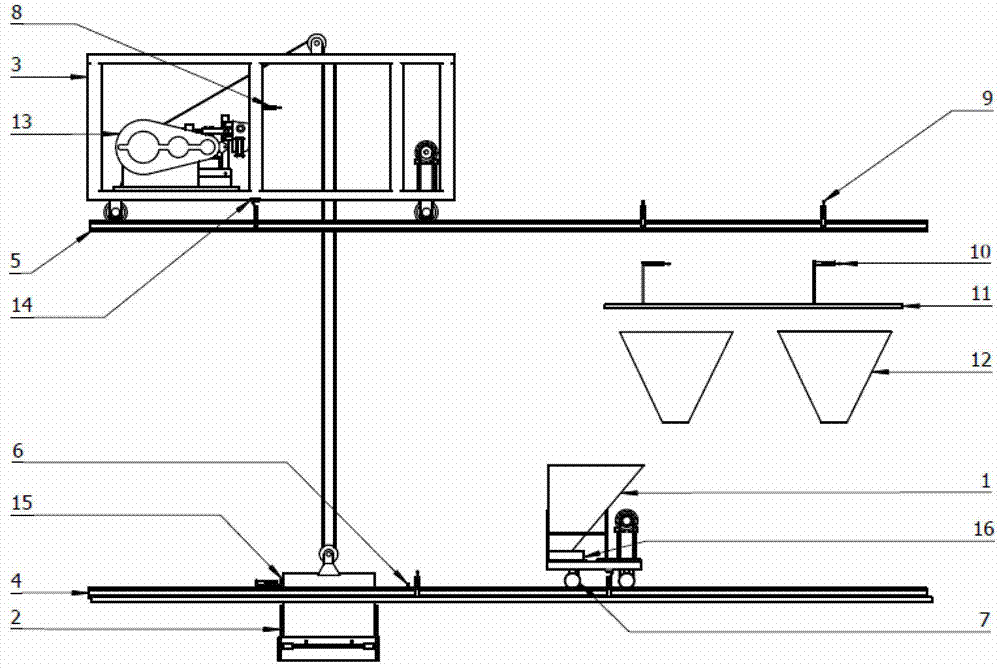

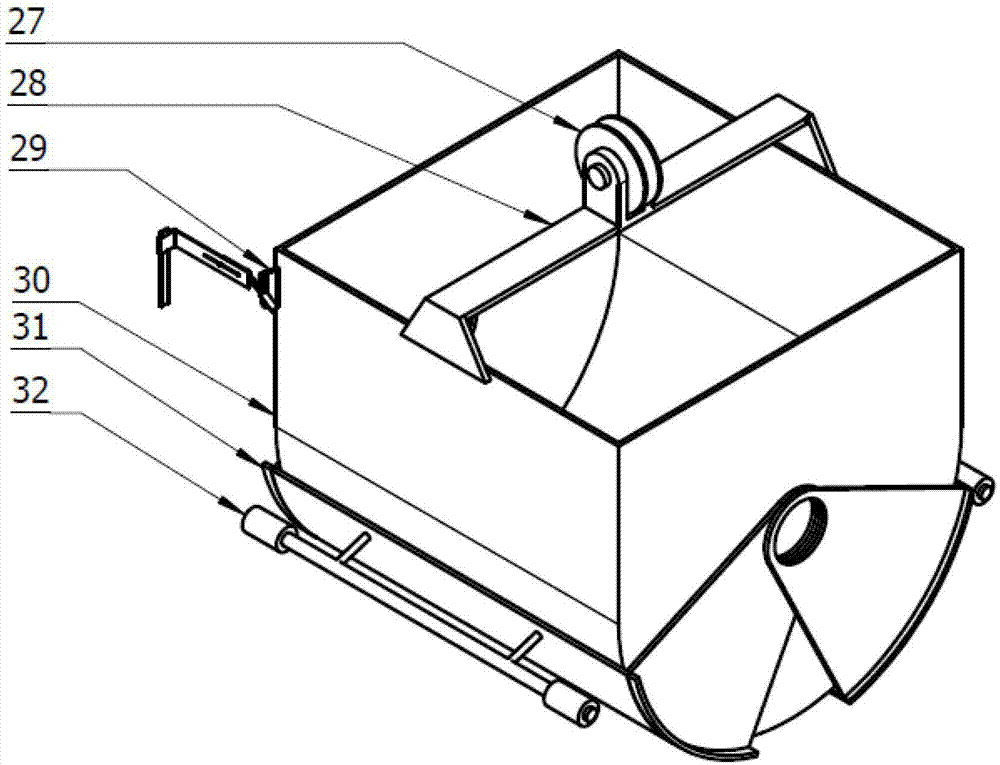

[0022] The multi-station automatic ore conveying equipment of this embodiment is composed of a loading car, a self-gravity opening and closing hopper, a ferry car, a track, a block, a bar, a travel switch, a discharge port, a touch screen, a programmable controller, It is composed of contactor, frequency converter, braking resistor, winch motor, traction motor and loading car motor.

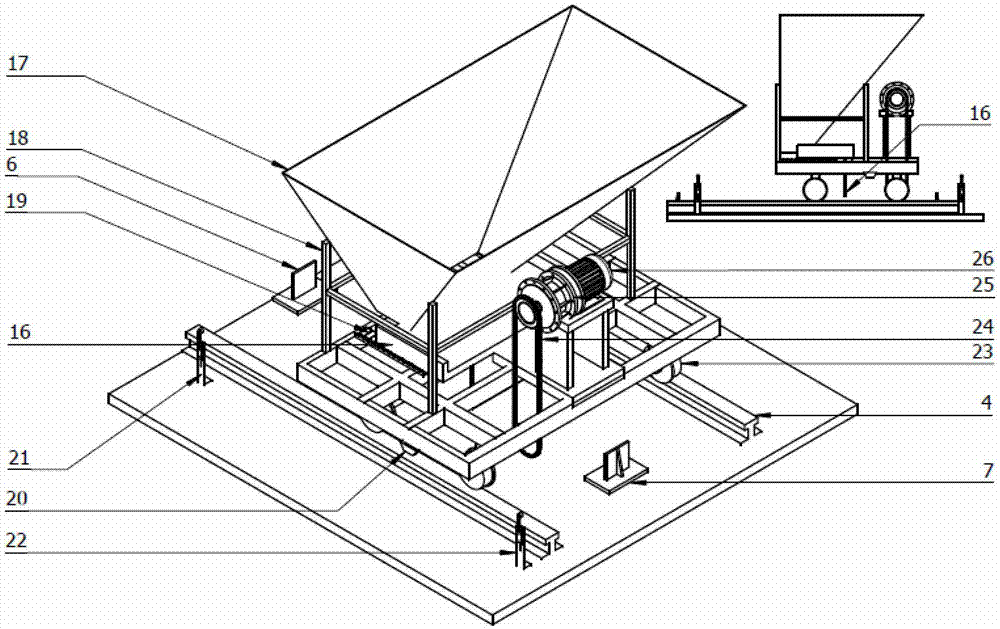

[0023] The loading vehicle cooperates with the track A on the ground, and its specific composition can be found in figure 2 , the car body support frame supports the loading hopper, and the hopper door baffle and rollers are sequentially assembled under the opening of the hopper. figure 2 In the side view of the upper right corner, it can be seen that a part protrudes from the bottom of the hopper door baffle. When this part hits th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com