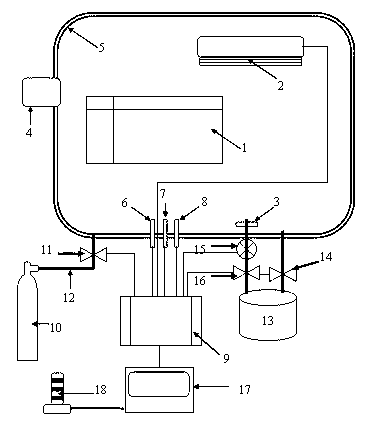

Selective laser melting (SLM) atmosphere protection system

A laser melting and protection system technology, which is applied in the direction of improving process efficiency and energy efficiency, can solve the problems of easy increase of oxygen content of forming objects, increase of production cost, impact on parts performance, etc., and achieve the effect of convenient quality traceability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below by specific embodiment:

[0021] As shown in the accompanying drawings, the selective laser melting SLM atmosphere protection system includes a metal airtight cabin 5 with a selective laser melting SLM forming working mechanism 1 inside. The air conditioner 2 is controlled and connected with the central control system 9 outside the metal airtight cabin 5, and the central control system 9 communicates with the host computer 17 with a man-machine interface. The airtight cabin body 5 is connected, and the inert gas pipeline 12 is provided with an air intake solenoid valve 11 that is connected to the central control system 9. The oxygen purifier 13 has two pipelines that are connected to the metal airtight cabin body 5, one of which is One pipeline is provided with a first valve 14, and the other pipeline is provided with a second valve 16, a circulating fan 15 and a molecular sieve 3 extending into the metal airtight ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com