Drive arrangement for a railcar and reversing gear

A drive device and transmission device technology, which is applied to the transmission device, transmission device, gear transmission device of a reciprocating piston internal combustion engine, etc., achieves the effects of balancing alignment errors, reducing manufacturing costs, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

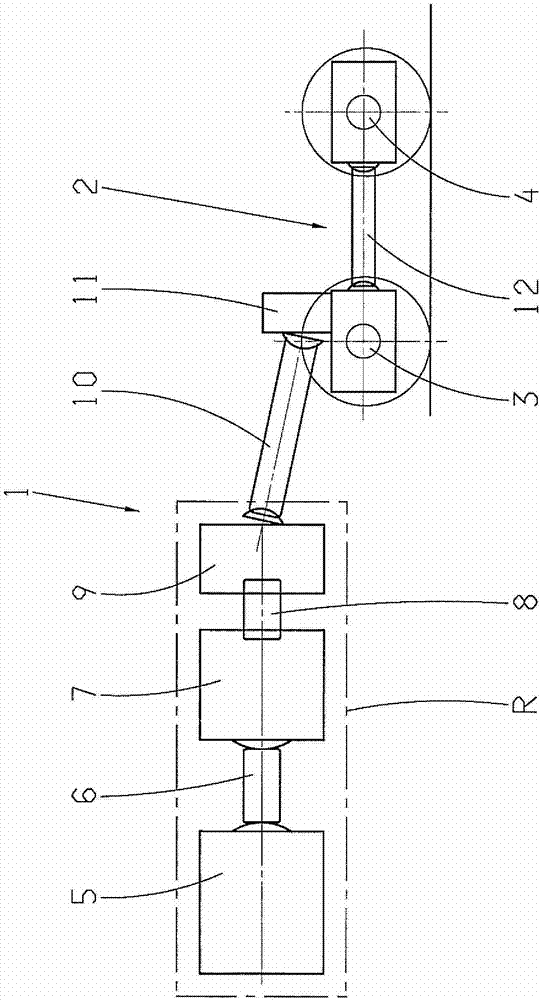

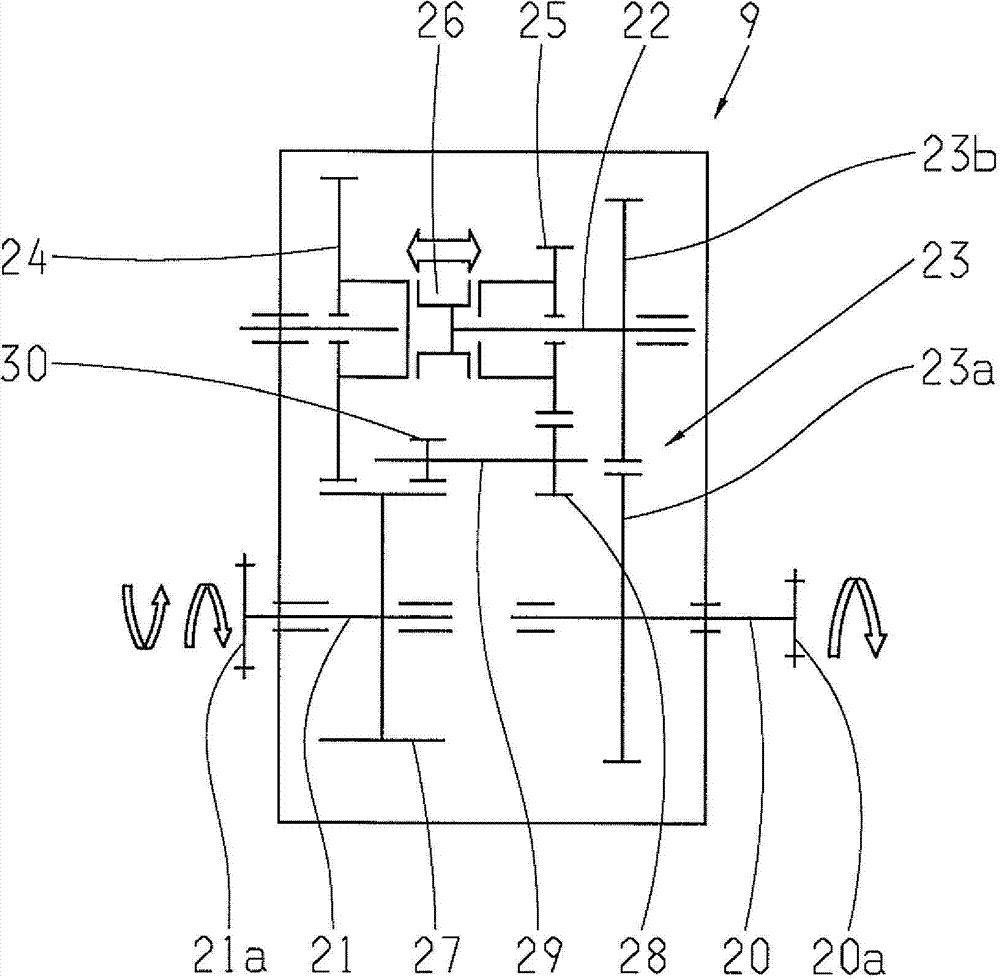

[0018] figure 1 A drive device 1 is shown for a motor rail vehicle (not shown), that is to say for a rail vehicle, which drive device is also referred to as a drive system. Seen in the direction of power flow, the drive device 1 comprises: a drive machine 5 designed as an internal combustion engine, preferably a diesel motor; a first cardan shaft 6; an automatic transmission 7; a clutch device 8; 10. Embodiments are also possible in which the drive machine 5 and the transmission 7 are directly flanged to one another, so that the cardan shaft 6 is omitted. The not-shown motor railcar has a frame, schematically indicated by a dot-dash rectangle R, and at least one bogie 2 . The drive assemblies 5 to 9 are arranged and fastened on or at the frame R. The bogie 2 is connected in a manner not shown to the vehicle frame R and carries the vehicle frame. The relative movement of the bogie 2 relative to the frame R is balanced by a second cardan shaft 10 , which drives the first veh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com