Method for stripping graphene with ultrasonic assist

A technology of exfoliating graphene and ultrasonic waves, which is applied in the manufacture of electrical components, circuits, semiconductors/solid-state devices, etc., can solve the problems that the area of graphene cannot be effectively controlled, the complexity of the process is increased, and the force applied to the manual tearing tape is uneven.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

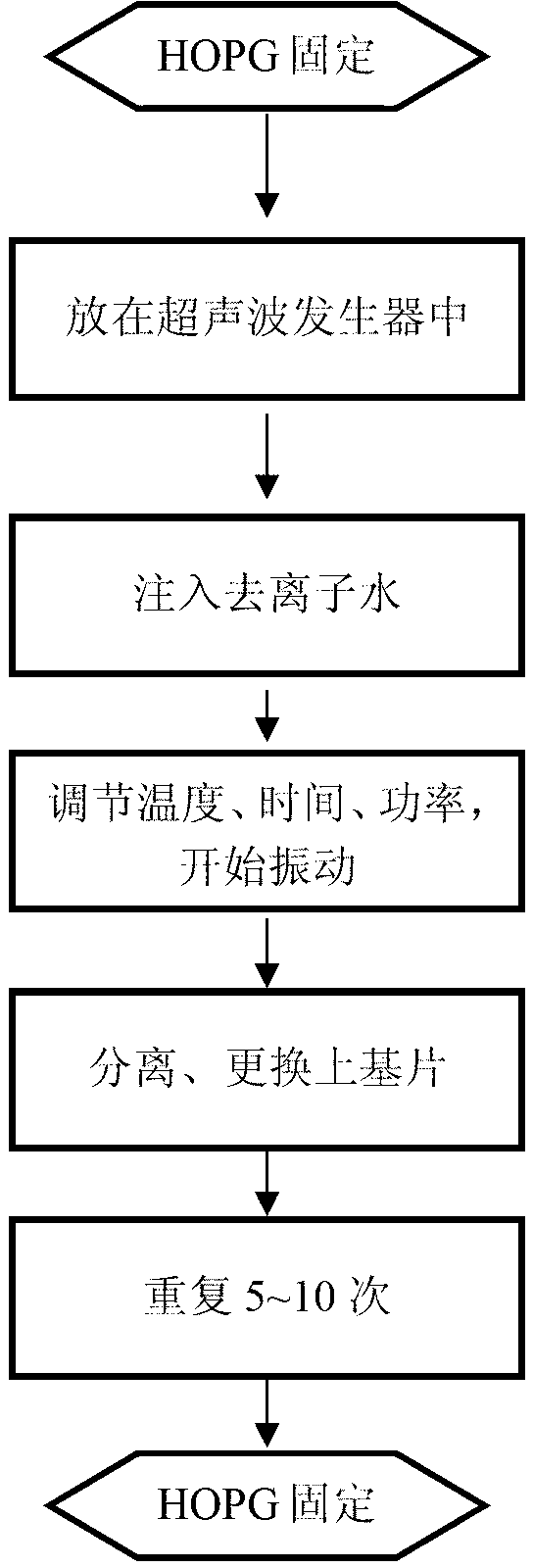

[0046] The realization steps of the present invention are as follows:

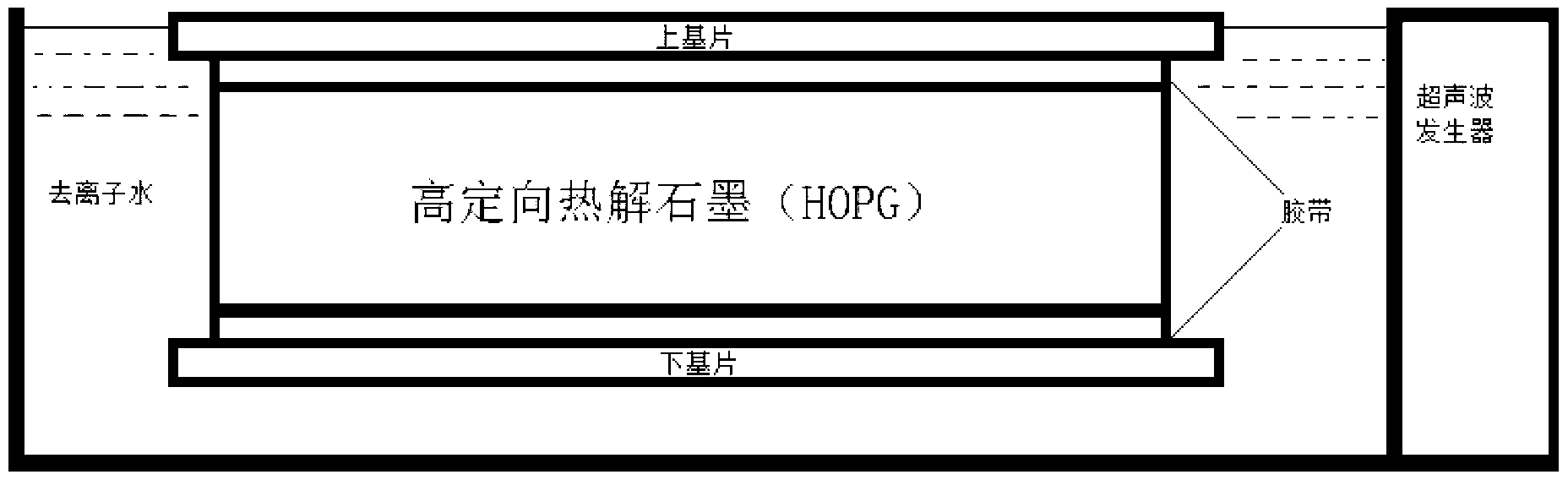

[0047] Step 1. Fix highly oriented pyrolytic graphite (HOPG) between the upper and lower substrates with double-sided tape.

[0048] Step 2, put the fixed HOPG into the ultrasonic generator, immerse in deionized water, adjust the ultrasonic power to 0.1×10 5 J. Time 10min, temperature 10℃;

[0049] Step 3, start the ultrasonic generator for lateral vibration;

[0050] Step 4, separate the HOPG from the upper substrate, and fix it under the new upper substrate with double-sided tape;

[0051] Step 5, repeat the above process 5 times until graphene is obtained.

[0052] Step 6, use analytically pure acetone to remove residual tape components on the graphene surface.

Embodiment 2

[0054] The realization steps of the present invention are as follows:

[0055] Step 1. Fix highly oriented pyrolytic graphite (HOPG) between the upper and lower substrates with double-sided tape.

[0056] Step 2, put the fixed HOPG into the ultrasonic generator, immerse in deionized water, adjust the power of the ultrasonic wave to 1×10 5 J. Time 300min, temperature 30℃;

[0057] Step 3, start the ultrasonic generator for lateral vibration;

[0058] Step 4, separate the HOPG from the upper substrate, and fix it under the new upper substrate with double-sided tape;

[0059] Step 5, repeat the above process 8 times until graphene is obtained.

[0060] Step 6, use analytically pure acetone to remove residual tape components on the graphene surface.

Embodiment 3

[0062] The realization steps of the present invention are as follows:

[0063] Step 1. Fix highly oriented pyrolytic graphite (HOPG) between the upper and lower substrates with double-sided tape.

[0064] Step 2, put the fixed HOPG into the ultrasonic generator, immerse in deionized water, and adjust the ultrasonic power to 2×10 5 J. Time 50min, temperature 40℃;

[0065] Step 3, start the ultrasonic generator for lateral vibration;

[0066] Step 4, separate the HOPG from the upper substrate, and fix it under the new upper substrate with double-sided tape;

[0067] Step 5, repeat the above process 10 times until graphene is obtained.

[0068] Step 6, use analytically pure acetone to remove residual tape components on the graphene surface.

[0069] The present invention has the following advantages:

[0070] 1. The production efficiency of graphene is improved due to the ultrasonic-assisted exfoliation.

[0071] 2. The production quality of graphene is improved thanks to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com