Detecting method and detecting device of driving board of inverter compressor

A variable frequency compressor and detection method technology, applied in the direction of electronic circuit testing, etc., can solve the problems of the detected drive board damage, the detected drive board breakdown, and the inability to make quantitative judgments, so as to improve the detection accuracy and efficiency , the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

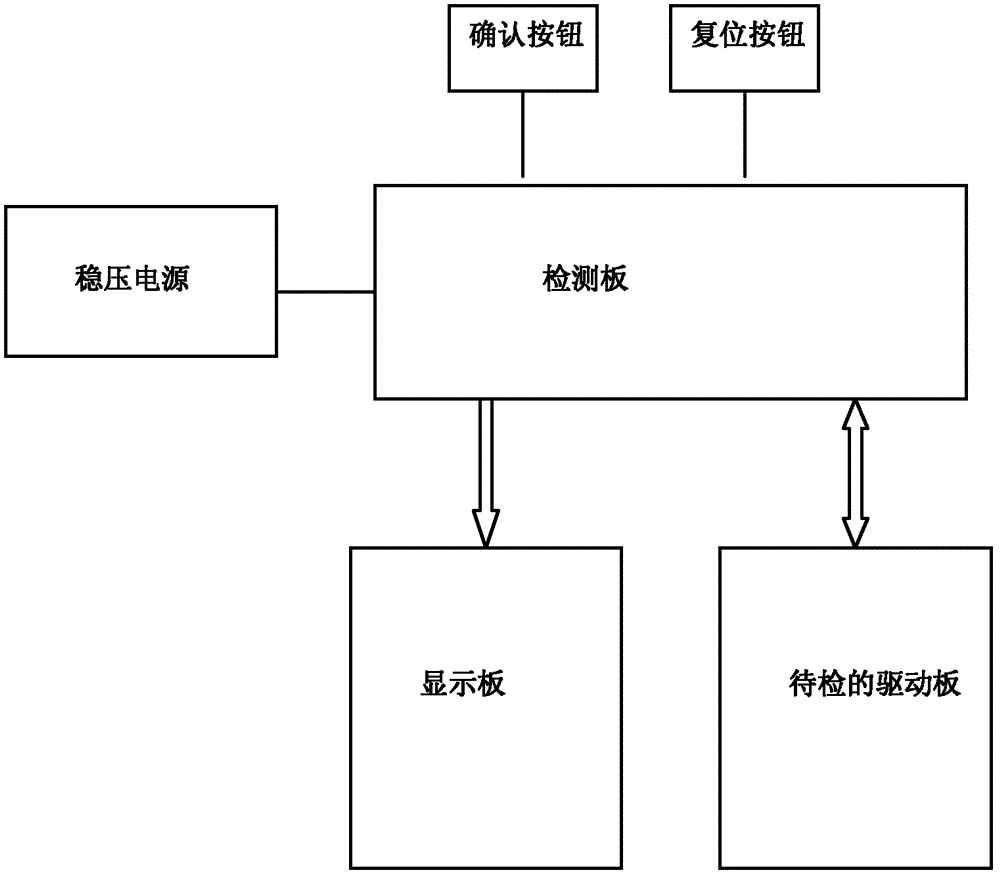

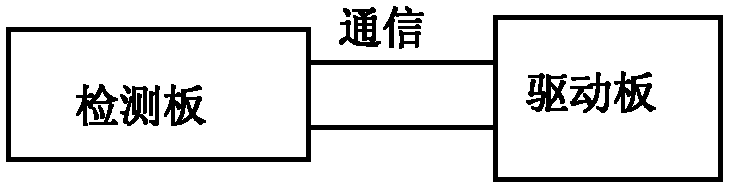

[0053] Example 1, such as figure 1 As shown, the detection device of the variable frequency compressor drive board externally receives the detection drive board and provides at least two isolated DC regulated power supplies.

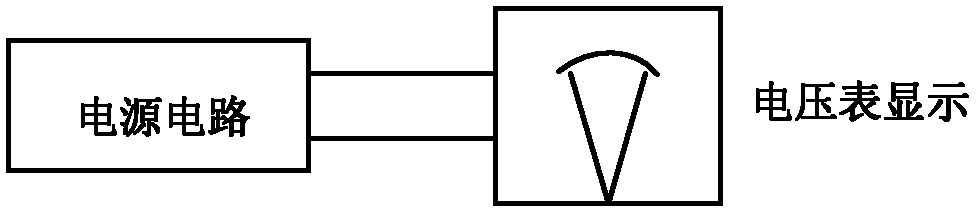

[0054] The detection device includes a detection board with an MCU, a DC stabilized power supply, a display board, a DC voltmeter, and an AC voltmeter on the periphery of the detection board, and a relay for timing control is arranged on the detection board.

[0055] The detection board adopts two independently provided, mutually isolated +15V weak power supplies to detect the IPM and IGBT functional circuits on the drive board to be detected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com