Moveable-gantry-based ultrasonic automatic flaw detection system for bent steel tubes

An ultrasonic and mobile technology, which is applied in the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. It can solve cumbersome processes, low detection efficiency, and unsatisfactory detection accuracy. The large-volume bending pipe production requirements of enterprises and other issues can achieve the effect of simple motion control, reduced labor intensity, and improved ultrasonic detection efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

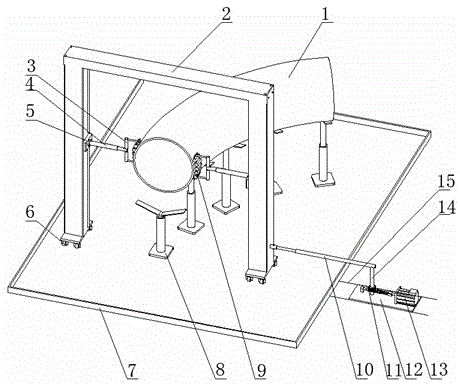

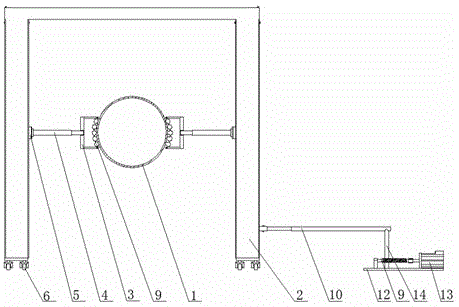

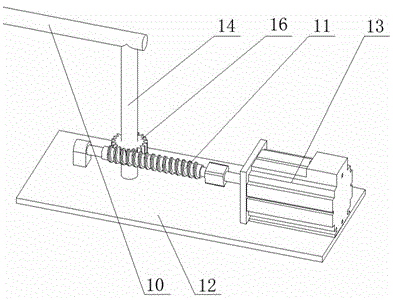

[0029] combine figure 1 As shown, the present invention adopts a method in which the mobile gantry 2 is fed axially along the bent pipe 1 to be tested, and the chain-type ultrasonic probe frame 9 moves circumferentially on the surface of the bent pipe for detection when performing ultrasonic testing. The system consists of a bent pipe holding base, a moving gantry type feeding mechanism and two sets of bent pipe ultrasonic detection mechanisms with the same structure. The bent pipe holding base includes a set of hydraulic cylinders 23, hydraulic piston rods 24 and V-shaped support frames 25 The hydraulic support frame 8 constituted, the mobile gantry type feed mechanism includes a mobile gantry 2, a feed pneumatic telescopic rod 10, a transmission worm 11, a transmission worm wheel 16, a transmission rod 14, a motor mounting plate 12 and a feed servo mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com