Test bed for hydraulic oil pumping device

A technology of pumping units and test benches, which is applied to the testing of machines/structural components, measuring devices, instruments, etc., can solve problems such as unrealistic and impossible oil well detection by manufacturers, and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

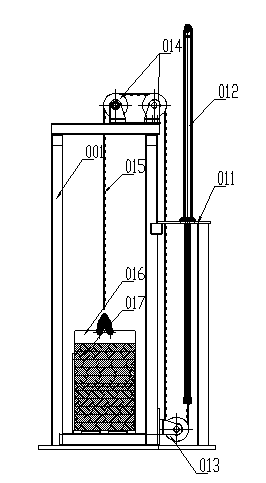

[0009] The hydraulic pumping unit test bench includes a frame 001, the frame 001 is a rectangular frame structure, a hydraulic cylinder mounting seat 011 is fixedly connected to one side of the frame 001, and a hydraulic cylinder is vertically arranged in the hydraulic cylinder mounting seat 011 012, the piston rod of the hydraulic cylinder 012 extends downwards into the cavity of the hydraulic cylinder mounting seat 011, and a direction-changing pulley 013 is fixedly connected to the frame 001 near the bottom of the cavity of the hydraulic cylinder mounting seat 011, and the frame The top of 001 is provided with a pulley block 014, and one end of the piston rod of the hydraulic cylinder 012 extending into the cavity of the hydraulic cylinder mounting seat 011 is connected with a steel wire rope 015. The load-bearing basket 016 in the framework of the frame 001 is connected, and a load-bearing code 017 is arranged in the load-bearing basket 016. The pulley block 014 is a plural...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com