Automobile test bench

A technology of automobile test and bench, applied in the field of automobile parts test and automobile, to achieve the effect of improving work efficiency, increasing installation convenience and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

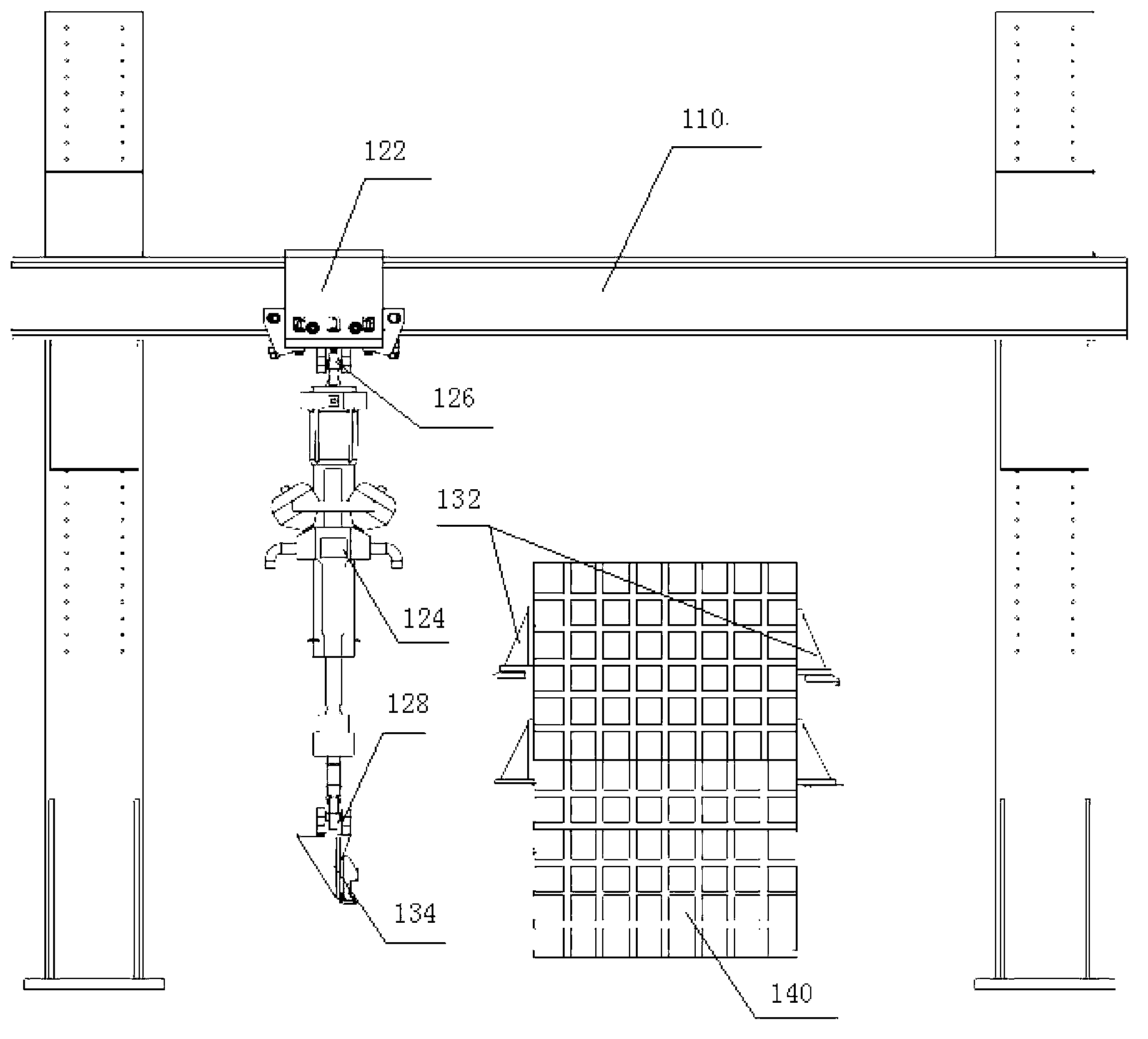

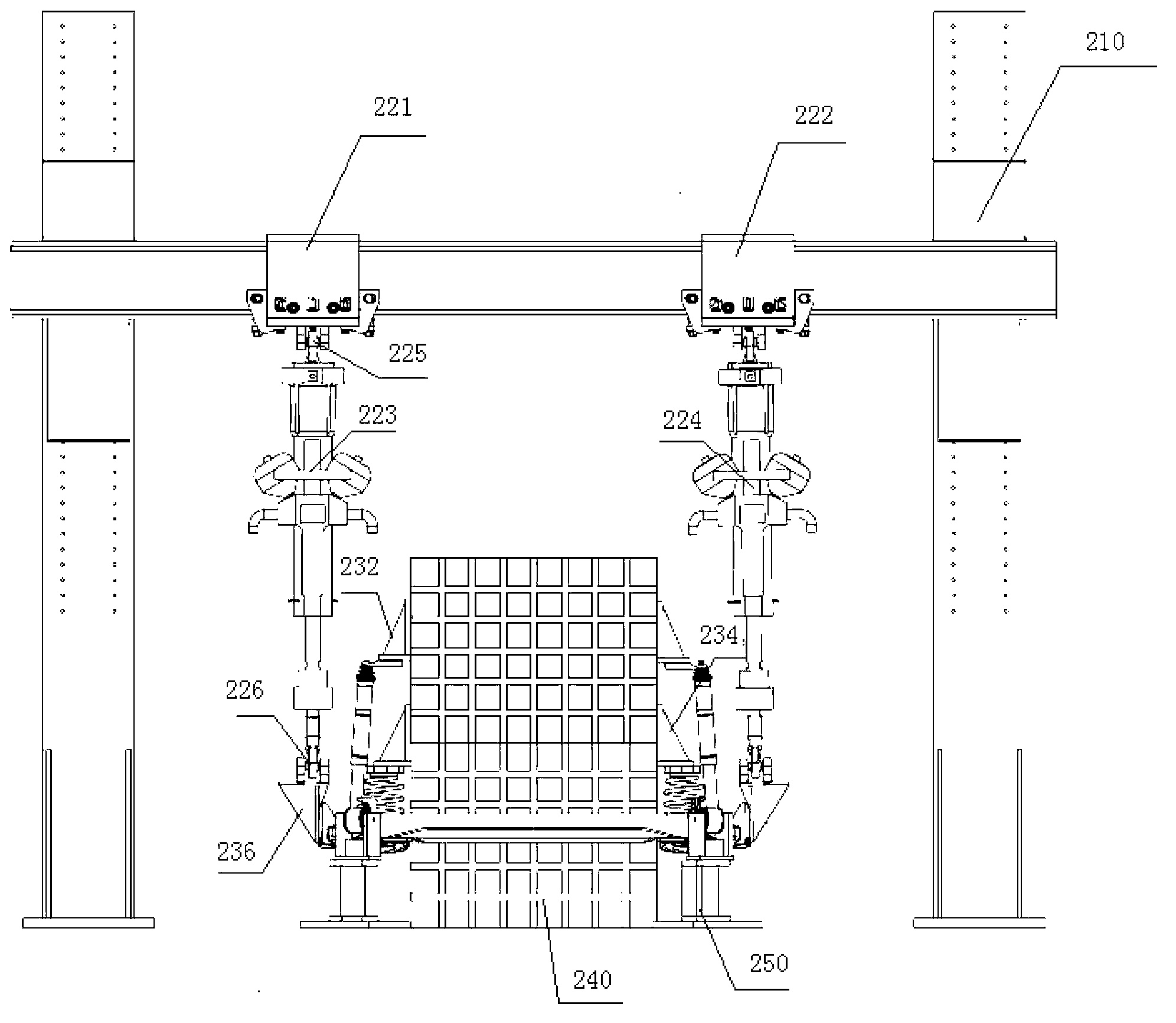

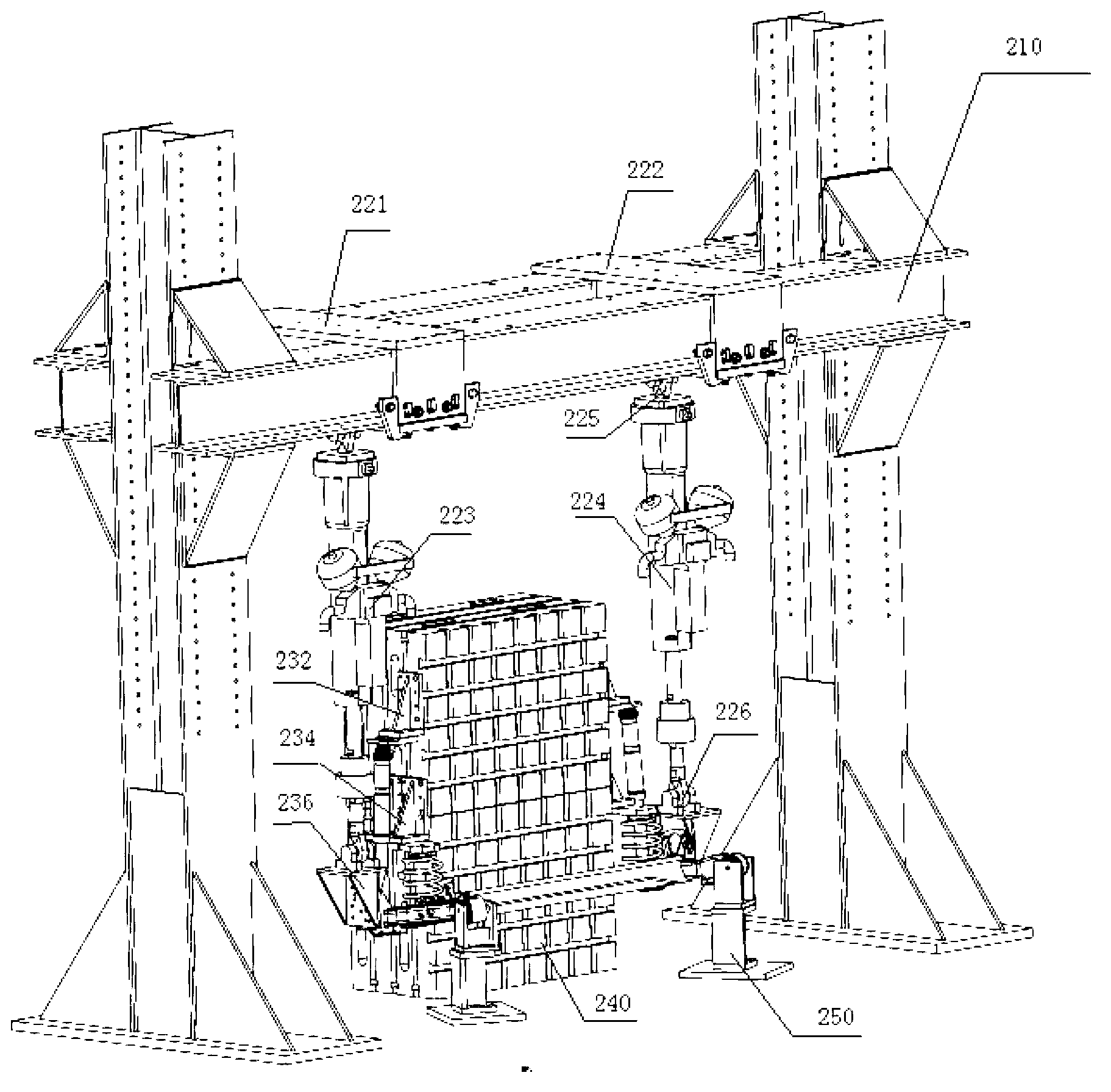

[0032] Such as figure 1 As shown, the present invention discloses an automobile test bench, including a gantry frame 110, at least one set of actuators, a clamp mechanism and a support mechanism 140 supporting the entire test bench structure, and the clamp mechanism is connected to the actuator and the support mechanism 140 respectively , used to fix the test piece, the actuator is installed on the gantry 110, including the sliding mechanism 122 installed on the beam of the gantry 110, the actuator 124, and the ball joints located at the upper and lower ends of the actuator 124, sliding The mechanism 122 is connected to the actuator cylinder 124 via the ball joint 126 at the upper end, and the clamp mechanism 130 is connected to the ball hinge 128 at the lower end of the actuator cylinder 124 .

[0033] The clamp mechanism includes at least one set of clamps 132 movably installed on the two side walls of the support mechanism, and one set of clamps 134 located below the cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com