Deflection automatic measuring device and measuring method thereof

An automatic measurement and force sensor technology, applied in the field of deflection measurement research, can solve the problems that the accuracy is difficult to meet the requirements of bridge deflection measurement, the accuracy and linearity cannot be satisfied, and the accuracy and stability are doubtful, so as to achieve simple structure and stable measurement data , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

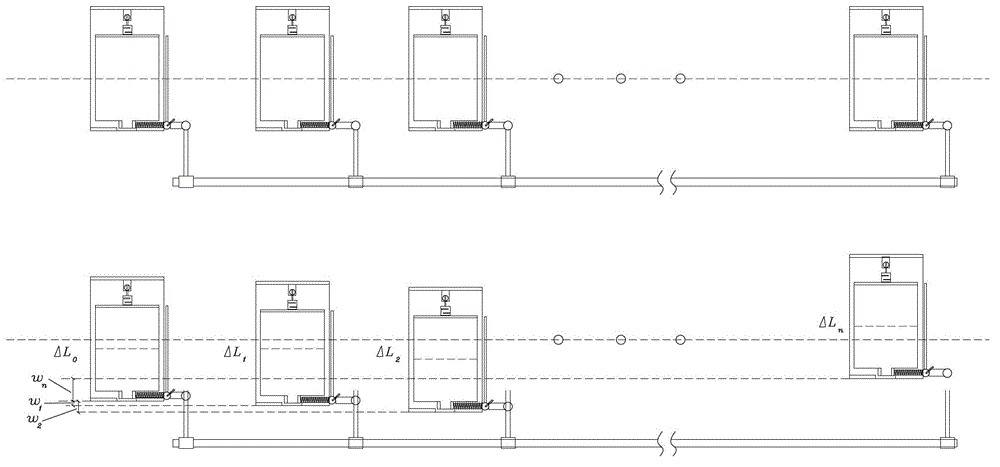

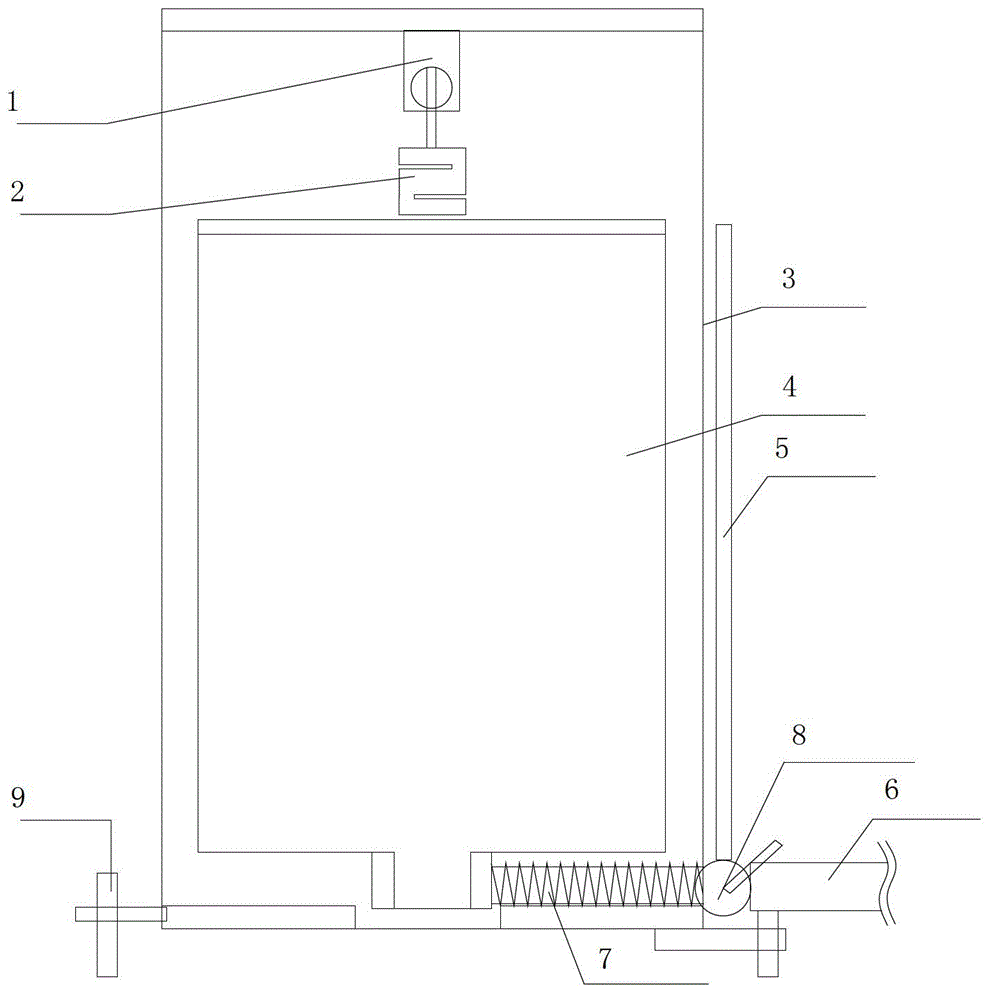

[0041] This embodiment uses multi-point measurement of bridge deflection to illustrate the specific measurement method and measurement device. Such as image 3 As shown, the simple and convenient connecting pipe 15 is laid out, then filled with water, and an elevated block is laid at the measuring point position, placed as figure 2 The shown measuring device 17 makes the initial water surface height of the transparent tube 5 equal to the initial line of the standpipe 4, and balances the vial on the outer frame 3. Turn on the switches of the flexible pipe 7 and the water inlet pipe 6 to allow the vertical pipe 4 in the measuring device to enter water. Connect the sensor signals of various places to the strain gauge and connect it to the computer. At this time, the data can be cleared. When the bridge is loaded, each measuring point will rise or fall, such as figure 1 and 3 As shown, according to the principle of the connector, the liquid level of each measuring tube will d...

Embodiment 2

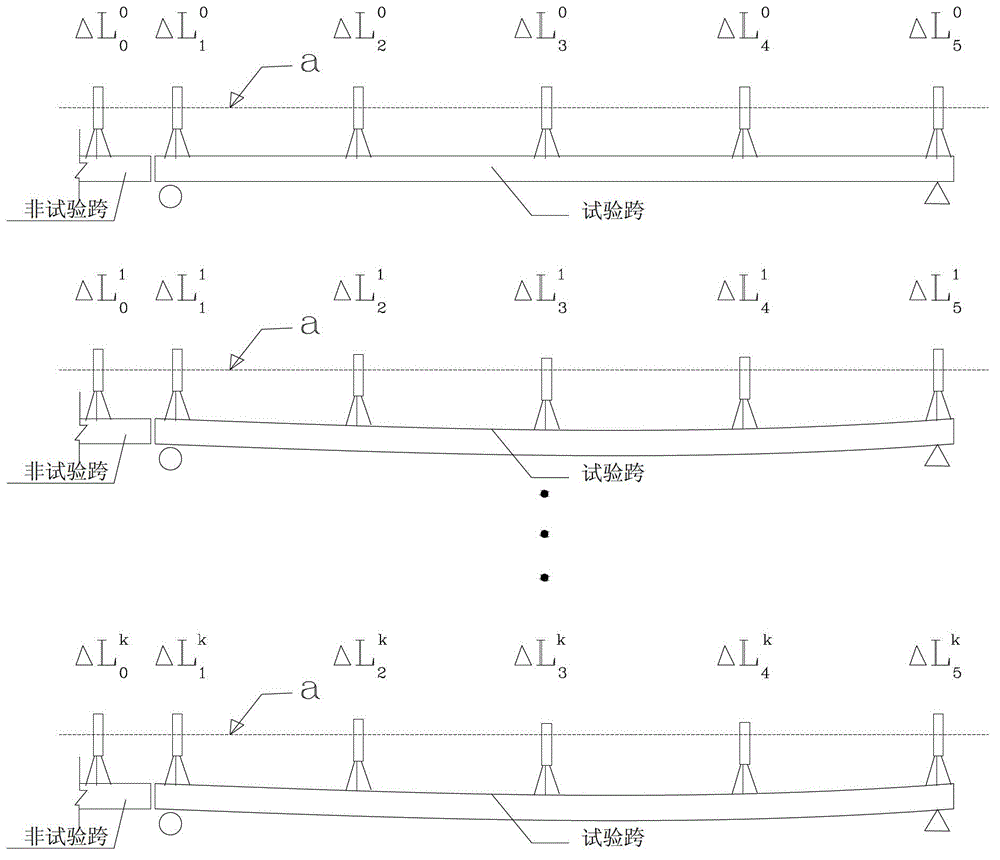

[0052] This embodiment has the same structure as Embodiment 1 except for the following features: in this embodiment, the device and method of the present invention are applied to measuring elevation or elevation, such as Figure 4 , 5 shown.

[0053] Choose vertical pipes of different lengths according to the total elevation difference of the measured structure (the measuring range needs to be large enough). On a reference point (such as the horizontal plane represented by a in the figure), the measuring device of the present invention is arranged, filled with water, and then another measuring device is installed on a movable mark post 16, which can be provided with a vial ( Or directly use the vial on the measuring instrument). Mark the position of the measuring point in advance according to a certain length (for example, the horizontal position of the measuring point represented by b in the figure), move the benchmark 16 to the measuring point in turn, and read the reading...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com