Confirming method for turbine standard backpressure in thermal power generating unit energy consumption assessment and coal consumption check test

A technology for thermal power units and steam turbines, which is used in the measurement of fluid pressure, instruments, measuring devices, etc., and can solve the problems of inaccurate data, lack of representativeness, and poor data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

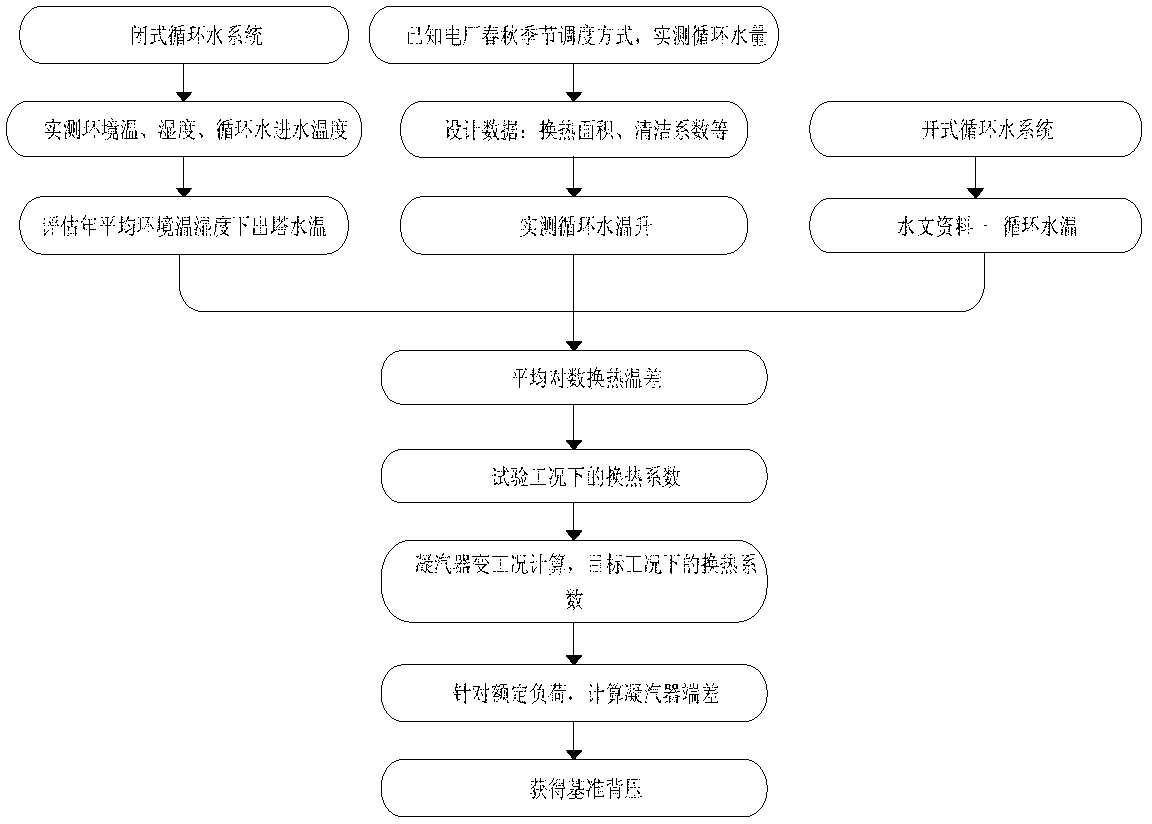

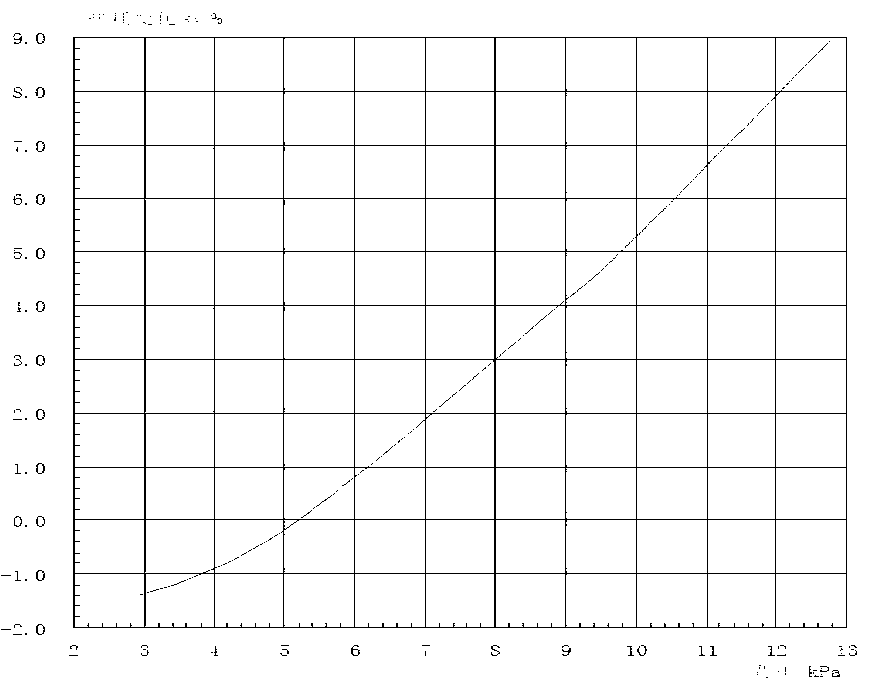

[0030] An example of determining the reference back pressure of a steam turbine in a thermal power unit energy consumption assessment and coal consumption verification test, see Figure 1 to Figure 3 , is to replace the rated back pressure with the reference back pressure, including obtaining the thermal performance of the cooling tower, the circulating water flow rate and temperature rise data of the condenser, and the heat transfer coefficient data through tests, and calculating the circulating water temperature and condensing steam according to the general process and formula The difference at the end of the condenser, and finally obtain the reference back pressure according to the characteristics of the water vapor. The general process and formula refer to: according to the inlet water temperature of the condenser, the temperature rise of the circulating water, and the end difference of the condenser, the saturation temperature corresponding to the reference back pressure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com